Making a convenient and safe staircase to the basement: what are the options?

Erecting the stairs to the basement, first of all, it is necessary to determine its purpose and operating conditions. This will allow you to choose the appropriate type of construction, as well as the material for its manufacture. Next, you need to make the necessary calculations and, having familiarized yourself with the methodology of the phased construction, to translate the project in wood, metal or concrete.

What to consider in the project?

First of all, you need to make a project. The following criteria should be considered:

- basement size;

- estimated size of the staircase;

- intensity of use of the stairs;

- load, which will be subjected to the stage;

- the staircase to the basement starts in the indoor or on the street;

- the quality of use of the intended staircase: how convenient it is to rearrange the legs, the height of the steps, the slope of the descent, the space width and other features;

- if the staircase starts inside the room, how much does it correspond to the interior;

- constructional features with complex specificity; it is important to evaluate possible critical moments;

- project cost.

Types and design choices

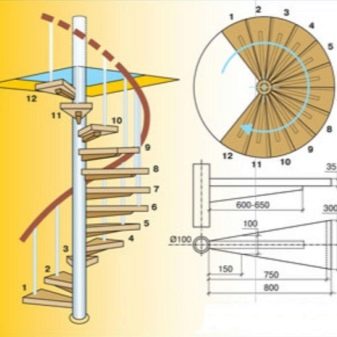

Screw

The main advantage of the screw descent is its compact size. This staircase consists of the following main parts:

- the rod serves as support for the whole structure, steps are fixed on it in a circle. Installs the rod on the support flange;

- steps;

- railings are almost always necessary, except in the case of a lined brick or other material.

Spiral staircases are made of metal and wood, less often - of concrete. Wooden options are almost always bought ready-made. In the manufacture of metal stairs using wooden steps due to low noise.

For such purposes, conifers, oak, larch are better suited.

Kosoura

The ladder on kosoura is notable for its ease of construction, low cost of materials and steps that can withstand high loads. Structurally, such a descent consists of several basic elements.

- Kosour is a beam supporting steps from the bottom. There are two main types: on the filings, they are the same teeth and filly. There can be several kosur, most often from 1 to 4. The kosour itself can be made of solid or glued board. The most durable species are oak, beech, ash.

- Steps can be with overhangs and risers, without overhangs with risers, without risers.

Boltsy

The technology of mounting the steps directly to the wall with special pins - bolzie. Between themselves, they can be fastened or be isolated. The main advantages of the design include: ease of installation, visual lightness that does not interfere with the review, durability and reliability. The main elements of the staircase are the following:

- bolza;

- steps Their thickness should increase with the width;

- railings, handrail, ceiling suspension.They become necessary with increasing width of the stairs;

- sometimes one string is added to the structure, which tightens the steps from the outside.

Performance materials

For the manufacture of stairs in the basement most often used three materials: metal, wood and concrete.

Each option has its own advantages and disadvantages appropriate for solving the problem with specific operating conditions.

- Tree - it is durable and lightweight material that has an excellent appearance, lends itself well to processing and has an affordable price. The main problem is the protection of wood from moisture, which is often present in the basement. In addition, she is interested in bugs and insects, as well as mold fungus.

- Metal - This is the most durable material for the stairs. It is easy to use: it is enough to mark and cut the sheet and the corners into the necessary parts, and then weld them among themselves. The main problem is corrosive processes, the entire surface should be covered with a layer of paint or enamel. At cost, the metal staircase is more expensive than wooden.

- Concrete. The main advantages of this material is its enormous strength and durability.The main disadvantages can be attributed to the large size, long construction time, high cost.

Concrete stairs are built only in large basements and preferably at the stage of construction or reconstruction of the house.

How to calculate?

Step width

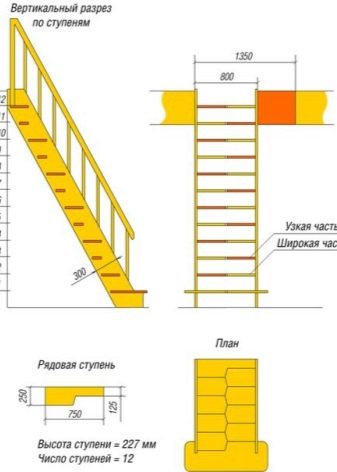

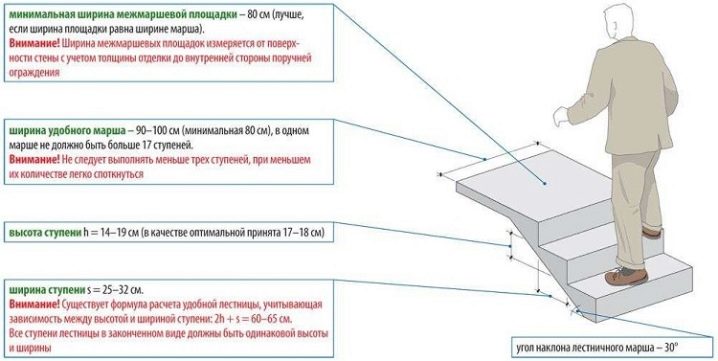

The passage should be quite wide, so that 2 people could disperse on it. The approximate width of steps from 80 to 90 cm will provide comfort and safety. Staircase of 2 marches, connected by a platform width equal to the steps. The staircase can be both steep and shallow.

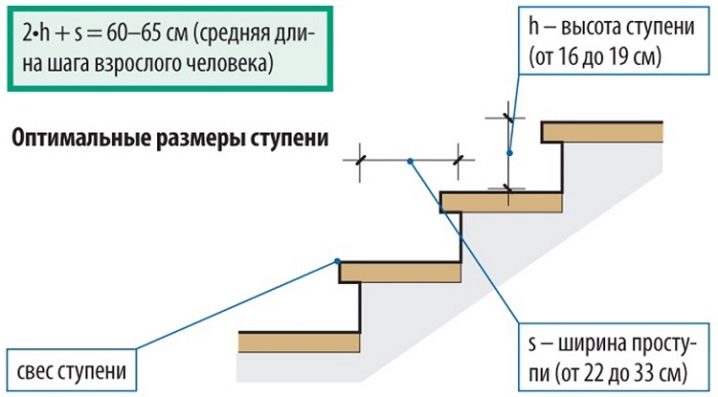

The standard is the ratio where the sum of the tread and the two risers is equal to the step length.

Step length and height

Suppose that the height of the basement is 3 m, the average height of the steps is from 15 to 18 cm, then it turns out from 17 to 20 steps. The average length of a human foot is 30 cm, therefore the length of the step should also be 30 cm. If additional finishing of the stairs is planned, all dimensions should be calculated adjusted to them at the planning stage.

Rotate the structure

Spiral staircases are compact and make a turn of 360 degrees - this is a great option for small basements.However, the descent of such a staircase is very steep and it is dangerous to carry loads along it. Marching structures are rotated by 90 and 180 degrees, less common are U-shaped variants. For the turning part is used playground or trapezoidal steps.

The variant with the platform is more simple in construction and operation due to the squareness of all the elements.

Manufacturing technology

Of metal

The metal ladder has the simplest design and is mounted on site faster than other types. To create it will need such details as:

- steel channel number 10;

- reinforcement bars;

- steel corner 50x50 mm;

- welding machine;

- angle grinder (Bulgarian);

- level;

- sheets of steel or construction board for steps;

- concrete.

Works are performed in a certain order, following which the creation of a metal ladder will pass without difficulty and alterations.

- Preparation of the base. Determine the area on which the structure will be based. A pit is dug out with dimensions about the width and length of 100x40 cm, 50 cm deep. Crushed stone is laid in the pit and cement mortar is poured in, leaving 15 cm unfilled. This cavity is needed to install the ends of the stairs and the subsequent pouring of concrete.Another option is to install two reinforcing rods with a cross section of 12 mm in a hole half filled with rubble. The ends of the rods should protrude 25 cm above the pit, after which the cavity is filled to the top with solution.

- Installation of the stairs. At the top of the channel are screwed with anchors to the ceiling. The distance between the beams is 90 cm. At the bottom, the ends, lowered into a 15 cm hole, are poured with concrete or welded to the reinforcement pins. If the construction assumes a turn, then the platform is boiled from the cut channel so that the edges protrude from three sides. With the help of projections, the platform is fixed to the wall on one side. On the other two sides, where the edges protrude, the upper and lower marches are welded. Steps are made of corners and welded to the channels from the inside.

- The final stage. Grinder removed all the tabs and trimmed edges. Metal surfaces are coated with an anti-corrosion compound. Steps are covered with sheets of iron or wood of choice. Rails are welded to side channels.

From wood

It is assumed that the wooden staircase is used in dry basements. Otherwise, its service life will be short.In any embodiment, the tree requires treatment with antiseptic impregnation. The design of such a ladder includes the following elements:

- wooden beams for kosouri;

- construction board;

- screwdriver;

- self-tapping screws;

- anchor bolts or dowels;

- jigsaw;

- Bulgarian or sandpaper.

The sequence of steps for the installation of a wooden staircase consists of several stages.

- Creating a framework. Cut a tread pattern. By its dimensions, applying to beams-kosouram, marked the locations of all steps. Using a jigsaw, teeth under the steps are cut from marks in kosoura. The edges of the gash are lightly processed with a planer and polished. Kosoura set at the required angle at a distance from each other across the width of the ladder. At the top, kosoura anchored bolts to the ceiling or in another way. Bottom fixation is carried out with metal corners. To do this, holes are drilled in them: the corners are fastened to the floor with anchor bolts through one hole, and the other side bars are attached to the corners.

An alternative is to attach the kosoura to the reinforcement concreted on the floor.The pit under the reinforcement is made according to the example of a metal ladder, but less scale.

- Manufacturing steps and additional elements. Steps, cut the same way, aligned and polished. Similarly made risers. It is important to observe the same dimension of parts, otherwise the ladder will twist. In the case of a two-track structure, the platform is installed on log supports attached to the floor, similar to the base of a ladder. Or fastens on the fittings built in in a wall.

- Build a ladder. The first sets of kosouri, next - steps, starting from the bottom. First, the first riser is screwed to the kosoura by screws, and a step board is fastened on top of it. Before fixing it is important to try on the elements and check the level of the horizontal riser. Railings are made of timber with a section of 80x80 mm, cut into 1 m, mounted to each or in one step. A rail is installed on top of the railing. The assembled structure is primed and painted.

Out of concrete

The ladder of this type is characterized by high strength, is not afraid of high humidity, durable. In addition, the design assumes the following conditions:

- large basement;

- durable floor on a strong foundation.

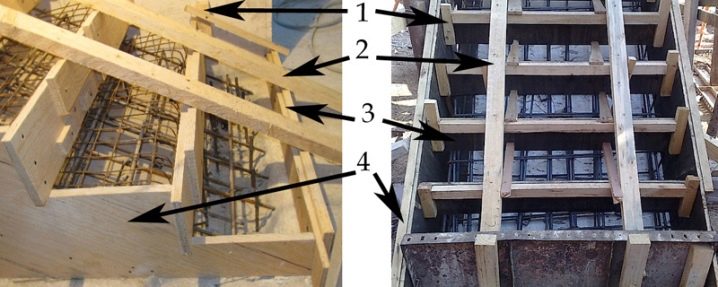

There are two options for the construction of concrete stairs. The first is a monolithic reinforced structure with the base resting on the floor as a whole. In the second set lower formwork, providing free space under the stairs.

Both designs can be performed near the wall, between two walls or in open space.

For the construction of concrete stairs will require materials such as:

- reinforcing bars;

- knitting wire;

- gravel;

- cement mortar;

- waterproof plywood 18–20 mm;

- construction board 30 mm thick;

- polyethylene film;

- self-tapping screws;

- wooden beam with a section of 100x100 mm;

- screwdriver;

- metal corner;

- level.

The sequence of actions in the construction of a concrete staircase consists of several main stages.

- Creating a foundation. For floors with solid screed foundation is not built, the surface is leveled to the level. Otherwise, the area corresponding to the dimensions of the base of the ladder is measured. The depth of the cavity should be 50 cm, rubble is poured into it and concrete solution is poured.

- Staircase frame, formwork installation. The first layer of the frame fits under the dimensions of the base of the ladder, the next one is attached to it minus the tread width and so on to the top. If the staircase comes into contact with the wall, the rods are driven into it and fit into the frame. The main condition for the frame: when repeating the contours of the ladder, its size by 3-5 cm should be inferior to the desired dimensions of the structure - this is a reserve for pouring concrete.

- If the ladder is being constructed with a gut, then the frame is reinforced by channels welded to the overlap, and an emphasis is placed from below. The mesh is tied to the reinforcing bars, its edges are bent for better grip. Under the step size, a template is cut out, on which plywood for the side planes is trimmed. In the case of a construction with sub-scoriated space, shields are installed below the frame and propped up by a bar.

Before pouring the mortar, the formwork is covered with a film from the inside.

- Fill The solution is poured in, starting from the bottom and carefully moving up, carefully ramming and leveling the filled mass. It is important to do it all at once, otherwise cracks cannot be avoided. Under the railings, space is reserved with wooden plugs.During the initial freezing of the solution along the contour of the stairs, a metal corner is pressed in and the surface is leveled with a trowel. A day later, the formwork is removed and covered with film. From time to time, the concrete is moistened with water from a spray bottle.

- Finish. Upon request and for security reasons, a railing can be installed. For these purposes can be used: metal corner and welded, as a handrail, shaped tube of small section. Steps can be veneered with tiles or other finishing material.

Making a staircase to the basement with your own hands is not difficult if you make the drawings correctly and follow all the above recommendations.

How to make a metal ladder with your own hands, you can find out further.