Plastic fence: advantages and disadvantages

Currently, in the building stores you can find a huge selection of fences. Plastic fences in the Russian market appeared not so long ago, so not everyone is familiar with this kind of structures. Thanks to the external attractiveness and ease of care, plastic fences are becoming more popular day by day.

Special features

A beautiful plastic fence can decorate any home, giving it a cozy and modern look, while such a model will be much cheaper than other options. With the help of plastic hedge it is possible to realize various ideas of designers. The very first fencing of polyvinyl chloride appeared many years ago in America. In our country, plastic products were first used during World War II.Simple installation technology will allow you to install the structure in a short time independently, without resorting to the services of specialists. PVC fence also performs a decorative function, decorating the landscape of the infield. If desired, you can make arches, gates, gates, suitable style.

The latest developments make it possible to improve these designs. For this reason product quality is improving daily. The manufacture of fences is similar to the production of plastic windows. PVC is an excellent frost-resistant material, which is also able to withstand contact with acids, fats, alkalis, salts and other substances. In its composition there are certain additives that protect the structure from external influences.

Based on the foregoing, it can be noted that plastic is ideal for the manufacture of fences. In case you need to implement a design in the European style, such a fence will be very appropriate. Before installation, you need to carefully study the area on which the structure will be installed, as well as draw up a project. If there are any obstacles in the territory, it is important to remove them very carefully and then mark the future fence.Where there will be bearing pillars, it is necessary to drive in small pins, connect them with a rope. The optimal installation step is considered to be 2.5 m or less. Making a marking, it is important not to forget about where the gate and gate will be installed.

Essential resins are used for the production of fiberglass fences, due to which such fences have a low weight, while maintaining strength. In addition, plastic models have a long service life.

Fiberglass sheets are well suited for low cost designs. Such fiberglass fences are mounted in parts - panels, so it is easy to install them.

pros

Plastic fences have their positive sides. It is necessary to consider them in more detail:

- attractive appearance. Plastic fences are good in quality and basic, and additional design;

- environmental friendliness;

- long service life. Such fences serve up to several decades;

- resistance to various influences. Plastic products are not harmed by the sun's rays, temperature variations and humidity;

- increased strength. PVC is stronger than many materials, for example, concrete or sheeting.The main thing - do not allow strong blows;

- ease of installation. Installation is possible to carry out on their own;

- ease of care. In case of pollution, cleaning and washing of the fence is carried out without the use of chemicals;

- low weight Due to this, installation and transportation of structures is not difficult;

- fire resistance Products do not ignite, therefore they are safe enough;

- a wide variety of patterns and shapes.

Minuses

Despite the abundance of advantages, plastic fences have disadvantages:

- Often, manufacturers make fences from low-quality and toxic materials. When purchasing fences, ask the seller for a quality certificate.

- Raindrops on white and beige fences leave dirty footprints.

- Painting products should be carried out exclusively by experts and only professional paint.

Kinds

PVC fence can be of various colors, types and sizes. If we talk about the size, then, as a rule, the maximum height of the construction of plastic is 6 m. Most often, two-meter fences are used to protect the territory of the dwelling.For decorative products prefer plastic sheets no higher than 1 m. To date, several types of plastic fences are known:

- picket fence This classic version of the fence is in particular demand among buyers and is a relatively inexpensive design. Between the panels leave a gap, externally, the panels look like a wooden board. Next to this design, it is recommended to plant flowers and shrubs, as it perfectly passes sunlight and air, while protecting it from wind gusts. The fence is great for areas with frequent winds and bad weather.

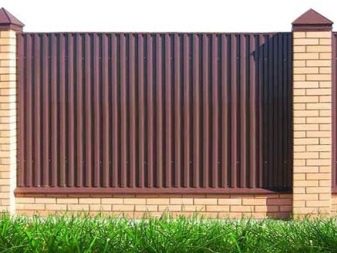

- deaf fence. Used to protect the home from outsiders views of others. The panels are mounted without gaps. A strong wind is able to destroy the construct, so to protect it set the frame of the metal.

This type of fence creates a shadow, so planting plants near it is not recommended. For additional decoration of the area, you can install small plastic fences.

- combined. On the site you can install a combined structure, giving elegance. Below is a monolith, and above it - braid.Such a fence will protect the area from prying eyes, and the owners will allow to see what is happening around;

- grid. This type of material is sold in rolls. The grid is an analog of the famous chain-link, only plastic. The strength of the metal mesh wins, but in appearance it is inferior to a plastic product. The grid is used for fencing the entire area, and for decorating flowerbeds and front gardens. To make such a fence more durable, it is additionally strengthened with metal wire;

- the fence. Current technology allows even to produce a polyvinyl chloride weave. Most often, wattle fence is installed in areas made in a rustic or ethnic style. This option of the fence plays a more decorative role, giving a special and unique look to the landscape.

Also, for decorating and isolating individual sections of a territory, they often use a sliding decorative fence.

Manufacturing

As mentioned earlier, similar plastic fences that meet the highest requirements have appeared in our country relatively recently. In the past, of course, there have been attempts to use PVC foam barriers, but the structures were not very durable, so people chose more reliable materials.Most often, a plastic fence was used for the front garden.

The situation has completely changed at the moment when the technologies used for the production of plastic windows began to be applied to the manufacture of fences. Modern fencing structures are made of polyvinyl chloride. It consists of a polymer compound and is characterized by increased strength and ductility.

Equipment for the manufacture of fencing products is a device that processes PVC. Plastic is heated to a fluid state, and then, under high pressure, is passed through molds called spinnerets. The result is a special configuration panel. They are used in the future for the production of the fence.

The panels are cut in accordance with the required dimensions, then they are joined, eventually sections are formed. For the connection used welding or mechanical elements. The fence is assembled both at the factory and directly at the facility.

A separate group of enclosing structures are metal-plastic fences. At the edges of the profiles, and sometimes in horizontal parts, reinforcing elements made of metal are installed.Typically, these elements are shaped tubes with a thickness of no more than 1.5 mm. Thus, at a fence strength increases. The quality of the coating of the fence directly depends on the components that make up the raw material for the manufacture of the product. These components include:

- stabilizers. Thanks to them, plastic gains strength. The use of stabilizers reduces the fluidity of the material, and therefore exposure to high temperatures does not deform it;

- plasticizers. They reduce the fragility of PVC. The presence of this component is especially important in regions in which the temperature of the air in the cold season falls below 35 degrees Celsius. If there is no plasticizer in the composition, then there is a risk that in the cold the structures will be extremely fragile;

- pigments. The most common color of plastic fences is white, so manufacturers are paying close attention to bleaching pigments. The highest quality and costly considered to be titanium oxide. It perfectly protects the surface from the appearance of yellowness. To enhance the attractiveness of fences used and other pigments. The higher the quality of the substance, the longer the pigment will resist exposure to sunlight without losing its original appearance.

There are cases when unscrupulous manufacturers add chalk to titanium oxide, and because of this, plastic quickly loses its former color. This applies not only to white designs, but also to all light shades, so when buying a hedge it is important to pay attention to the composition of the product.

Reviews

Customer reviews of plastic fences are varied. The owners of such structures include the undeniable advantages of an attractive appearance and the almost complete absence of the need to care for the product. As a disadvantage, consumers called expensive fences, as their price often exceeds 20 000 rubles. Also, some have noticed that plastic fencing is best placed on the site, in the yard area.

The growing popularity of PVC structures confirms that they have more advantages than a disadvantage.

Beautiful options

Today, you can find a large assortment of various types of plastic fences in various shades. Demand are white, beige, gray fences. Some consumers combine these tones in one design. Fences in bright colors are made to order.

The combined fence of white color beautifully looks.He ennobles any home, brings comfort.

It is possible to decorate flower beds and flower beds with a braided juicy green color. This option will be original, it is ideal for decorating the site of a private house or cottage.

Attractive look fences of dark shades. For example, a dark brown fence with an unusual arrangement of panels will emphasize the excellent taste of its owners.

How to install a plastic fence-lattice, see the following video.