Rules and subtleties of the choice of pipes for the fence

Arrangement of any private site involves the construction of fences. These designs are made of various materials, among which special attention should be paid to metal pipes. Production differs in the small weight and a practicality that allows to carry out installation even independently. When buying it is important to consider the rules and subtleties of the choice of pipes for the fence. This will create not only durable, but also beautiful designs that will fit into a particular exterior.

Special features

The pipe is one of the most demanded materials at construction of fences, protections of balconies, terraces of a country house. It can be used as the main and auxiliary element. Very often of this raw material make support columns.For such purposes, use several materials:

- Metallic pipes. The main products with which it is very easy to work. The material perfectly bends, which allows you to give the design of various shapes and dimensions.

- Asbestos pipes. This raw material is durable, but it is rather fragile, which does not always allow its use with other substances. Fence of asbestos cement pipes are most often found in industrial plants.

Some professionals may complement fences. PVC pipes. But this product is not the main one, as it is intended for solving completely different tasks.

The design of the pipe intake is practically no different from systems of other substances. There are also supporting pillars, between which there is a decorative layer.

It can form both from the same pipes, and other construction materials.

Fences of this type have several significant advantages:

- Durability and strength. The metal frame can withstand significant loads, and with proper care does not give in to corrosion. Structures resist external physical loads well, which is much better than wood.

- Pipes can be mounted in spans of any length. This is important because it allows you to build not only durable, but also beautiful structures around the perimeter of the territory.

- It is easy to restore the fences simply by replacing the broken part or by welding an additional piece of steel.

- Products are perfectly combined with other materials. Therefore, pipes are often supplemented with a metal profile, stone, forging and other structures. Sometimes fences are formed from only one pipe, giving them a different geometry.

One of the drawbacks of the fence from the pipes is that the material does not cover the territory. If you need to protect the site from prying eyes, you will have to sheathe the metal with a profile or polycarbonate sheets. This, in turn, may already affect the decorative appearance of the surface.

Types and materials

Fences in most cases are made of metal pipe, which has a certain margin of safety. Conventionally, these structures can be divided into several types:

- Sectional fencing. This design consists of several sections, which are made in factories. Their installation involves the installation of a profile support pipe and suspension of the partition to it. This option is not always convenient, as it does not differ in beauty and originality.But all modules are qualitatively protected, which allows extending the service life of the metal several times. To perform such welding work at home is quite difficult and time consuming.

- Welded fences. Receive them directly at the construction site. For this, a frame is welded from the profile to which the decorative elements are then attached. Designs of this type are much more reliable than the previous version. But at the same time they require more thorough treatment with protective compounds in order to eliminate the rapid formation of corrosion.

Depending on the section of the pipe, materials for fences are of several types:

- Square. The profile tubes are durable, but not always practical. Squares are good to dock with each other, which gives this type a special popularity.

- Rectangular. Pipes of this type are the most popular in the construction of fences. Metal profiles have an optimal ratio of strength and cost.

- Round. If we take into account the strength characteristics, then such products are the most durable and reliable. They withstand the loads that the profile construction is not able to transfer.Of these pipes, screw supports are often made, supplemented with a special thread. Such a structure allows the screw to be screwed into the ground, without using concreting for fixing.

The use of plastic structures is rare, since the material is not particularly durable and can not withstand high loads.

In the manufacture of pipe fences can also be used several auxiliary materials:

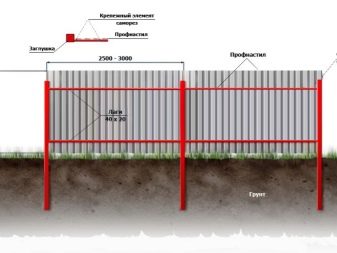

- Decking. Sheets fit perfectly with the profile structures. Mounting them is relatively easy and quick. Therefore, this combination is very common.

- Tree. With wood, simply decorate the frames. Both vertical piers and longitudinal decorative boards can be attached to the pipe.

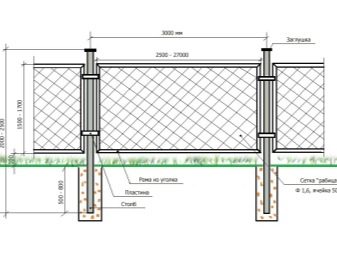

- Metal grid. This product is used to create simple and practical fences. For the connection of these materials can be used as spot welding, and special screws. Such structures are often prefabricated, as they are made in factories.

- Forged Products. Pipe designs are often decorated with forging, which gives them originality.It uses curved fittings and decorative elements in the form of flowers. Such materials require good welding skills, so it’s best to trust its experienced specialists.

What pipe sizes to choose?

Fences of any type are subject to significant loads that the frame must withstand. Therefore, when a professional pipe is selected, it is important to consider this factor. To determine the optimal dimensions of the structural elements can, following simple recommendations:

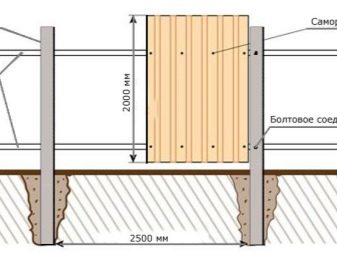

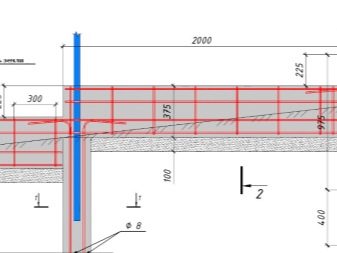

- The cross section of the pipe depends on the height of the fence. With a fence height of 1.8-2.2 m, it is better to use profile products with a section of 8x8 cm. If you decide to use round elements as a stand, then the optimal indicator is 6 cm in diameter. For small fences, the cross section of pipes can be from 40x40 mm to 40x50 mm . It should be understood that a thin frame will not be able to withstand heavy finishing and strong winds.

- To get a solid system, you should use elements with a wall thickness of at least 3 mm. This value increases in proportion to the load on the fence.

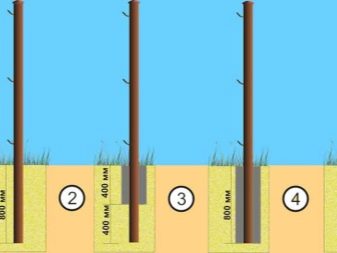

- If the support posts will be buried in the ground without a concrete foundation, then it is advisable to dig them in to a depth of 0.8-1.2 m, depending on the density and structure of the soil.The softer it is, the deeper the metal should be placed to ensure optimal resistance to wind loads. This characteristic is important to consider when selecting the length of the workpiece for the uprights.

- The cross section of the longitudinal lag is slightly smaller than the indicator for support columns. Often for a classic fence need a pipe size of 40x20 or 40x25 mm. It is desirable to increase this parameter only when the distance between the supports exceeds 2.5 - 3 m.

- When the installation of the gate with the fence is planned, then thick structures should be used for such purposes. The cross section for support under the gate should be not less than 10x10 cm, and the thickness should exceed 4 mm. But it is best to replace them with solid metal blanks that will last much longer. It should be understood that the round tube is much better suited for solving such problems. Therefore, it is used in the construction of the gate.

To do fences from polypropylene pipes is undesirable. The material is poorly welded and is not able to withstand temperature extremes and high loads.

Features of the installation of the intake frame

The installation of a metal fence is a relatively simple process, requiring only experience with welding and other plumbing tools.The construction of the framework of this type can be divided into several successive steps:

- Design and selection of materials. Externally, the frameworks for fences are rectangles that are constructed from several shaped pipes. In order to calculate the amount of materials, it is necessary to measure the perimeter where the fence will be located. After that, you decide on the dimensions of the canvases, and on the basis of these data you can find out the necessary amount of products. Here it is important to take into account also the cross section of each attribute, which will allow you to select the desired amount of profiled pipe.

- Perimeter markings. This process involves the formation of smooth lines along which the fence will be located. For this you can use several pegs and thread. It is important to note where the posts will be installed in the future. It is desirable to consider their thickness in order to cut even horizontal lintels in the future.

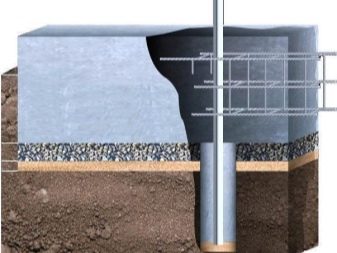

- Digging holes under the pillars. They can be made by special holes, which will exclude the use of shovels. If the fence is not long, you can form a small foundation for it.This minimizes the risk of contamination of the decorative layer during rain, and also strengthens the entire structure. For this method, one should dig a small trench along the entire perimeter.

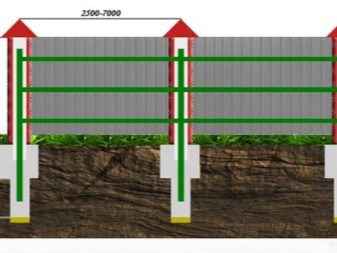

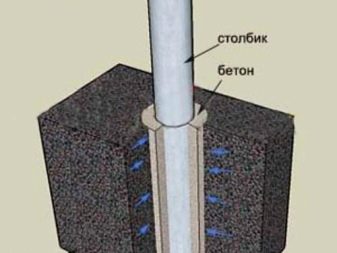

- Pillar installation. This process involves the strengthening of the support in the pit. The simplest option is to fill the structure with concrete. If you do not have the opportunity to do it, then you can simply seal the pillar with rubble and sand. It is important to place the support strictly vertically so that it does not move. In the case of concrete, it is advisable to install additional struts that will not allow the metal to deviate from the vertical. After the mixture hardens, these elements are removed.

- Jumper installation. They are simply welded to the posts by welding. If you do not know how to work with such a tool, then you can fasten the elements with metal screws. But the latter method is not particularly effective, since it is difficult to obtain a solid structure of high strength. Please note that the number of jumpers should be selected depending on the height of the fence. If this parameter exceeds 1.5 m, then 3 horizontal binders should be used.In another case, 2 elements are enough.

- Installation of decorative coating. Fastening technology depends on the material used for plating. For example, the metal profile is simply screwed with special screws with sealing rubber on the head.

To protect the metal from corrosion, it is desirable to cover it with several layers of protective paints.

It uses both primers and compounds that are intended for external climatic conditions.

Successful examples and options

Proper selection of pipes for the fence to make it possible to make this fence not only reliable, but also beautiful.

Although it was mentioned in the article that fences do not make plastic pipes, however, someone managed to make quite an attractive fence from this material. Of course, it will not save from large animals and intruders, but it will demonstrate skillful hands and creative master and will allow to determine the beginning of private ownership.

Metal pipes for this welded fence are selected in its exact style.

And in this case, asbestos pipes were painted in red, and metal caps of the same color were put on top.The latter are selected under the metal lining on the wooden fence, from which the fence itself was built. In the end, everything turned out quite decent and interesting.

For how to install the fence post, see the next video.