Subtleties of the choice of blocks for the fence

The fence is the main attribute of any dacha. One of the main requirements that impose on this design is strength and originality. Such parameters are typical for intake units. They are made from a variety of solid materials with unique technical characteristics. Therefore, before buying this product should consider some subtleties of the choice of blocks for the fence.

Special features

Blocks for fences are artificial materials of a cubic form. They are made of various solutions, which after solidification form a solid and solid structure.

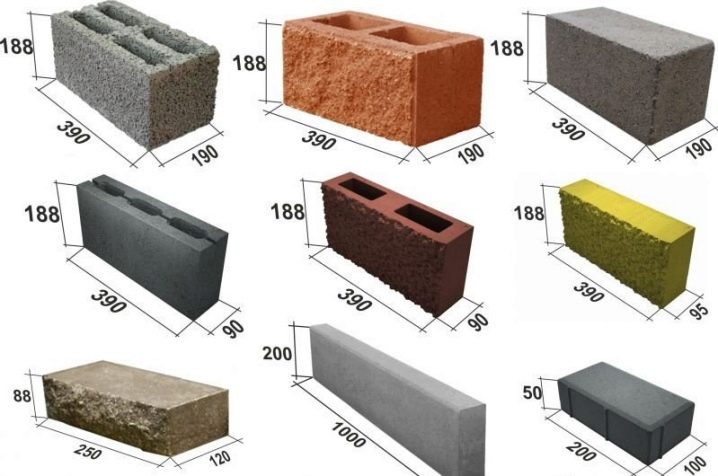

Outwardly, they resemble a brick, differ in large size. Most of the blocks for the fence hollow.Such a structure allows to obtain the optimum ratio of strength and low weight. There are also solid products, which consist of solid concrete or other solution.

Blocks are a versatile building material used to build not only fences, but also small posts or fences. Some manufacturers produce them in the form of prefabricated elements, which, when docked, form a brick with empty space inside. With the help of such products it is easy to hide the metal supports of the fences, creating a uniform style of columns and canvases.

Advantages and disadvantages

Fence blocks are used throughout construction, as they have several advantages:

- The construction of fences is accelerated several times. This is achieved not only due to the larger size, but also the correct geometric shape. Laying a rectangle does not take much time, since it is easy to align it in all planes.

- Low price. They make blocks by artificial means, which makes it possible to reduce the cost of production in comparison with natural stone. This is influenced by the large volume of the element that can replace several bricks at once.

- Strength. This indicator may vary depending on the structure of the product.Some blocks perfectly tolerate frost, do not absorb moisture, and also withstand significant loads.

- Minimal care. The fences of these products can be operated without restoration for a long time. In this case, the top layer practically does not lose its original characteristics.

- A variety of designs. Many manufacturers complement the top layer with various decorative effects. This allows you to use them when creating original landscape solutions. The blocks are perfectly combined with metal, wood and other building materials.

- Blocks do not burn and do not sustain combustion. This makes them safe for use in factories and other specific places.

- Durability. Some types of blocks can serve up to 100 years, which is not always possible to achieve from a brick or wood.

Blocks for the fence do not always allow to use them in specific conditions.

This is due to such material cons:

- Laying a substance takes a lot of physical effort, which is not always practical.

- Great weight. Withstand the fence of the blocks can only strip the foundation, which must be additionally constructed before laying material.

- High price.This feature is relative, since it all depends on the size of the fence and the products used. For example, a brick structure will be much more expensive, since it will be necessary to spend more material.

Evaluating the positive and negative sides of the blocks, it can be noted that they are great for building durable structures. In this case, all the shortcomings are leveled with the passage of time and are not so significant.

Kinds

Blocks for fences are classified according to several criteria. Depending on the structure of the upper layer, they are distinguished by the following types.

Construction

These are the usual blocks that are used for the construction of fences. They also have cavities inside, but the upper layer is completely even. Externally, such products are unattractive, so they are often used for the equipment of fences in industrial plants. Differ in considerable weight, therefore their installation is not always convenient alone.

Decorative

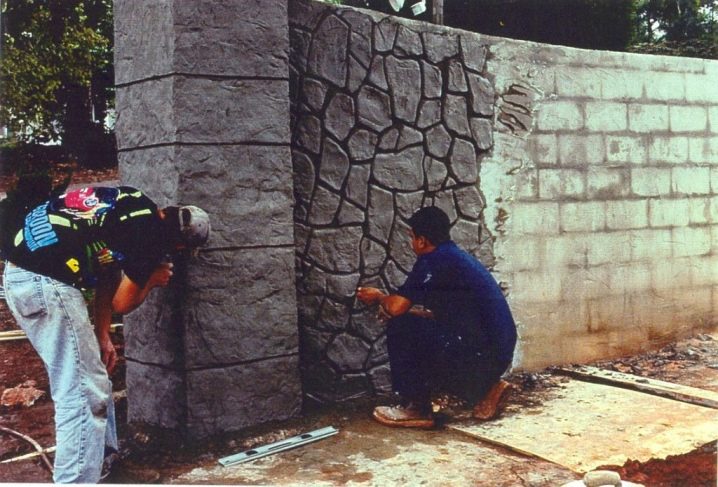

Make them from the same materials as the previous form. They differ in a textured outer layer, imitating a different structure. These blocks are valued in construction and are used almost everywhere.

By production of blocks use clay, an artificial stone and concrete.But in the manufacture of such products use a lot of fillers. Depending on this, there are several types of materials.

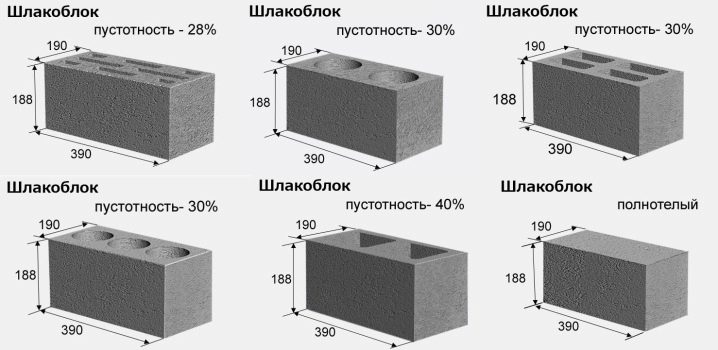

Slag

Slag is used as a filler, which perfectly retains heat and has a low weight. Different types of this substance can change the shade of the block. This allows you to change its color, but without applying an additional layer of paint.

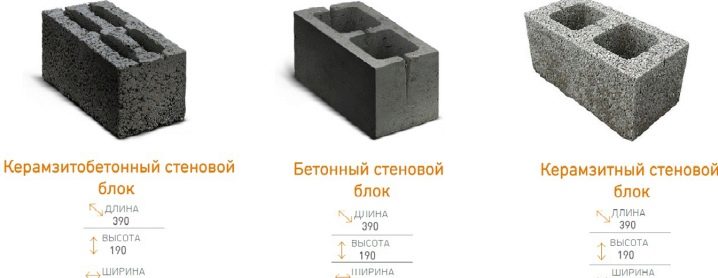

Ceramsite blocks

In their structure, they are largely reminiscent of the previous type, since expanded clay is burnt clay. With it, reduce weight, and also give the block texture.

Concrete blocks

Almost no filler is used here. Such products are also called besser, which corresponds to the well-known manufacturer of these units. Many manufacturers add gravel, sifting or gravel to the composition. They allow you to strengthen the structure and increase the strength and durability of the blocks.

Foam blocks

This group includes blocks that are obtained from various components using the technology of their foaming. Bright representatives of foam blocks are gas silicate and aerated concrete products.Most manufacturers produce solid foam blocks, but there are also hollow variants.

Products made of sandblock are used for the construction of pillars. These column materials may vary in small size and weight. Standard block sizes are 20x20x40 cm.

On the market there are other dimensions:

- 39x19x18.8 cm

- 38x9.5x18.8 cm

- 39x19x40 cm

The form

Today, all types of blocks for fences are rectangular in shape. But they can differ only in the structure of the upper decorative layer. The simplest products are made with a smooth surface. The advantage of such options is their quality docking during installation. Outwardly, they do not bear any decorative load and are used only as a building material in places where decoration is not so important.

Particular attention should be paid to the decorative block, which has a ragged surface. On the surface of these products, a piece forms a rough structure that resembles a crushed stone (the second name of these products). With the help of such products it is easy to imitate almost any texture of natural materials. But the cost of such a block is much lower than natural products.

Decorative design

Today, many manufacturers are trying to diversify the style of the blocks to give them an attractive look. This expands the scope of their application and makes popular similar building materials.

Intake blocks can imitate several types of substances:

- The brick.

- Slate

- A natural stone.

- Tile.

To give naturalness blocks painted in different colors. Colored designs can be painted directly on site after installation. This approach is often used by designers to create unique structures and styles. Particular attention is paid to the shades that are present in nature.

"Stone" products are suitable for almost any design, as they can withstand high loads and are compatible with various construction approaches. If you use flat blocks, then they can be decorated with additional finishing. It is easy to glue ceramic tiles, natural stone or apply decorative plaster on the concrete surface.

Reviews

Products based on concrete and its derivatives have been popular for quite some time. Many people buy blocks of this type, as they serve for a long time and reliably.The owners note the high strength of the fences, as well as their resistance to winds and other climatic factors. Products very well cope with the loads, and also minimizes the cost of operating fences.

The disadvantage of decorative elements, users consider poor attachment of paint on the concrete surface. According to reviews, over time, it begins to flake off and fall off. To restore the surface and give it the original look, you will need to completely remove the old coating, and apply a new layer of paint. But it all depends on the paints used for decoration.

Professional Tips

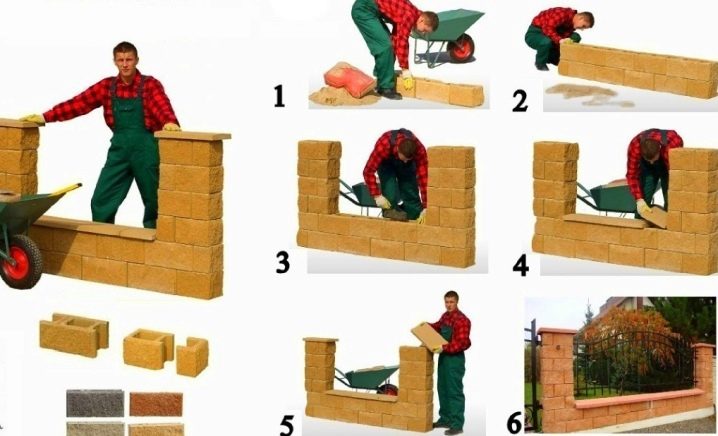

Working with fence units is not particularly difficult. But today not everyone knows how to properly stack and monitor such substances.

Therefore, in the construction of fences of such products should be guided by such rules:

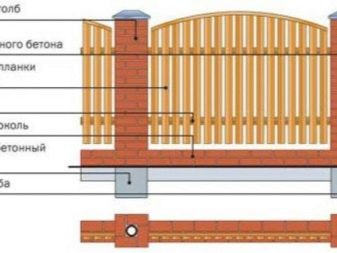

- Monolithic columns of blocks must be not less than the height of the fence itself. If you miss this, then you can get a non-persistent system. Experts recommend installing vertical supports at a distance of at least 3 m from each other.

- Colons necessarily associated with the foundation.To do this, use reinforcement, which is laid in the base at the stage of its filling. The location of the reinforcement depends only on the shape of the support that will bind the fence.

- Laying the blocks must necessarily assume their vertical and horizontal reinforcement. To do this, between each row element in the solution have a reinforcement that binds together all the components. Vertical reinforcement is done with metal meshes. They are also inserted between the blocks, but only in the vertical plane.

- Between each block should form a seam, the thickness of which should be at least 1 cm. It is important to fill them completely, without leaving air voids. If they are present, it can lead to rupture of the material with water during freezing, as well as reduce the strength of the structure.

- In construction, use only quality material from well-known manufacturers. Cheap products are not always manufactured to standards, which reduces their strength characteristics

Fence blocks are a versatile building solution. Qualitatively laid elements allow to reduce costs,and also to give the surface an original and pleasant structure, so it is advisable to install the installation team of experienced professionals who will do everything quickly and reliably.

How to build a fence, see the following video.