How to make the gate with your own hands?

Arrangement of any territory involves the presence of a fence. Mandatory attribute of this design is the gate to ensure smooth penetration of the object. Such systems are used both in industrial enterprises and in private areas. Products of this type may vary in complexity and design. Preliminary training will allow you to choose the best version of the product, taking into account all the nuances.

Special features

Gates are universal fencing structures that are installed at the entrance to a specific object or private territory. Today, there are many varieties of such structures, which allows you to select them depending on the destination.

No matter what type of gate is considered, the product consists of several basic elements:

- Canvas. This part is the main part of the whole system. Depending on the design, there may be several webs. Some models may have a complex geometric shape, attached to create a unique design.

- Supports. These products take the main load created by the sash or leaf. The shape and technical features depend on the method of fastening the gate.

Gates have several distinctive features:

- Simplicity. Making some modifications does not require knowledge and experience with different materials.

- Durability. Quality products can last up to 15-20 years with proper care.

- Ease of management. Today, all types of gates are complemented by special hinges, rollers and other systems that simplify the opening of the valves.

- A variety of designs. Products are made using various materials and approaches. This allows you to get not only durable, but also beautiful products.

Kinds

Gates are an integral element of many enterprises and private estates.These designs should solve several universal problems. You can build them today yourself, using special drawings or sketches. Depending on the technical parameters, the door systems can be divided into several types.

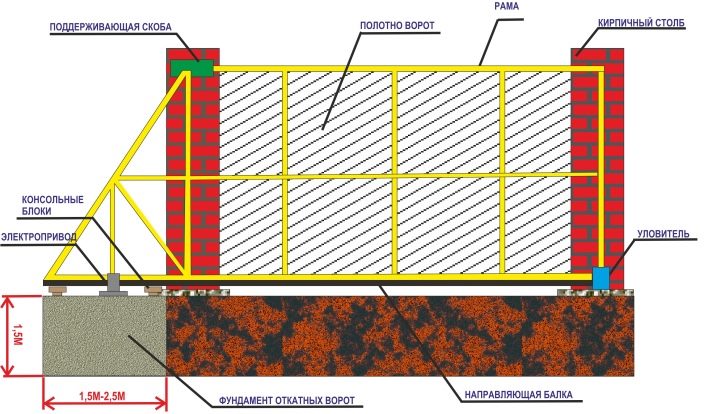

Recoiling

The leaf of such a gate moves parallel to the fence or one of the walls. The main components of the products are canvas, cantilever beam, rollers and supports. The attachment scheme of these attributes depends only on the selected type of sash and its location.

The displacement of the frame is due to the cantilever beams and rollers.

The most popular type are cantilever gates, but there are also suspended, and rail systems. The latter, for example, are very similar to the console, but the movement is carried out on a special rail. There are also so-called folding gates. As if the sash enters into itself. This is achieved by the use of metal profiles of various thickness and its fastening. Sliding gates are universal, as they can be installed both at the cottage and at an industrial facility.

Among the shortcomings can be identified the need for free space on one side, as well as the high cost of production.

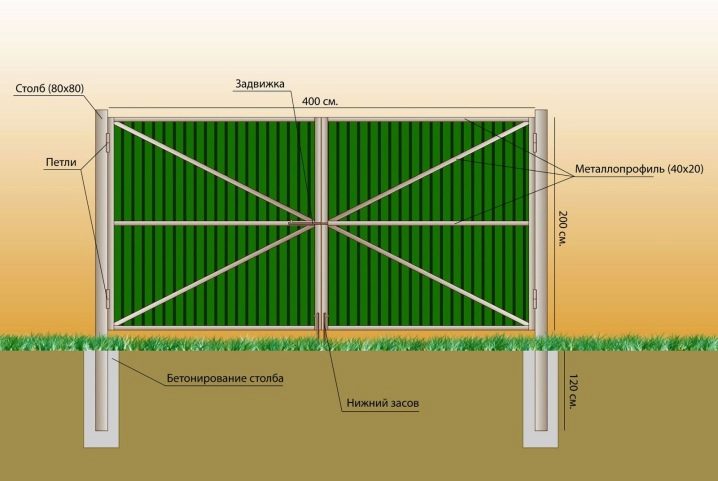

Swing

Gates of this type consist of one or two leaves that open in an arc. The use of swing systems today is very diverse. They are used both in private households and in large agricultural enterprises where additional fencing is needed for the territories. The construction of this gate is one of the simplest, which led to their wide distribution. For their installation, you will need metal and welding, with which the frame of the canvas is welded, and after the gate is installed in the right place. Today, swing gates are used as entry gates.

One of the drawbacks of the canvases is the need to have space in front of them for their free opening.

Rolled

A feature of such structures is that the web is wound on a special shaft when moving up. This was made possible by dividing the web into small sections that are interconnected. Theoretically, the rolling doors can be installed on the street as protective systems, but this process is quite labor-intensive, so they are mounted in garages or in warehouses, where you can attach the frame to the base of the building.Among the disadvantages of these structures can be identified their small strength.

There are varieties in which the canvas does not curl into a roll, but folds into an accordion, but they are used quite rarely, since they are not so practical.

Sectional

Gates of this type consist of a large canvas of several sections, which moves along special guides. Apply these systems in the construction of large warehouses, garages and other industrial facilities. In order to increase the heat insulation, a heater is inserted inside the web. The gates go up, so no extra space near the base is required. Some modifications can be supplemented with windows and wickets.

Among the shortcomings can be identified high cost and limited use (installation is carried out only on solid grounds).

Swing-out

This type of gate is a type of sectional modification, only here the whole canvas is used as the base. The rest of the functionality is practically no different from a similar type.

Materials

Theoretically, the gate can be made from almost any material.Today for such purposes apply several types:

- Metal sheets. Often for such purposes they use a professional sheet, which is selected in thickness and color. From it form the canvas itself. Pay attention that with iron sheets not only sheathes a skeleton, but also form the top layer of rolled mechanisms. To protect the metal surface coated with PVC solutions.

- Pipes. Both round, and profile products are applied. Self-made doors are often made from the profile: you just need to properly weld the workpiece.

- Metal corners. They are necessary to create or strengthen the frame. For heavy gates this material does not apply.

- Wood. This material is the most accessible and common, but the wooden gates are less common today, as they are quite demanding of climatic conditions.

- Metal rods. They make decorative items. They are the basis of wrought iron gates, which are distinguished by originality and beauty.

How to do it yourself

Gates can drastically differ from each other in design and technical parameters.The construction of some modifications is technically impossible at home. These include suspended or rolled varieties.

Before you start building the gate in a private house, you should consider a few recommendations, act in stages.

- Decide on the type of construction that you plan to build. Today, many prefer rolling systems, but they need free space along the fence. This must be considered when planning. At this stage, it is advisable to make all measurements in order to have data on which the basic parameters of the web will be calculated.

- Calculate all the parameters of the canvas and the gate (if it is). To do this, it is better to make a small drawing on which you should put all the main dimensions of the future sash. Particular attention should be paid to the console and fan systems: for them the accuracy is most important.

- Stock up tool. The construction of certain types of gates requires not only the presence of a hammer and welding, but also other auxiliary tools: circular, Bulgarian, and many others.

- Before starting work, buy building materials in the right amount: plastic pipes, tubes, rollers, hinges and the like. The required set is determined by which gate you are going to build.

Installation of supports

Technically, supports can be called the elements of the system that hold the canvas in a certain position. These structures take the main load, so they are constructed of durable materials. The easiest option is to install fence posts for swing systems.

It consists of several consecutive steps:

- Initially determined with location. Often, for double-leaf gates, supporting columns are positioned at a distance equal to twice the width of one leaf plus a small margin. It is also important to take into account the direction of motion of the web If it opens into the courtyard, then you need to leave room for plowing.

- Concreting pillars. Concrete structures, a wooden bar or a metal channel of various thickness are used as supports. They are selected depending on the weight of the gate. When concreting, it is important to deepen the pillars not less than 50 cm. It is desirable to expose them strictly vertically, since any displacement may affect the possibility of closing the valves.

- When the concrete is poured and the pillars are exposed, it is necessary to mount the brace so that the pillars do not change position during the hardening of the mortar.

Installing a support system for sliding panel doors is a more complicated process.

It can be described in several points:

- Digging a ditch under the lower support beam. It will take the bulk of the departure sheet. The moat is located along the opening, and its length often does not exceed half its width. The depth of the pit reaches 1-1.5 m.

- The construction of the beam. This construction consists of a steel channel and metal supports that are welded to it. As a result, the whole structure resembles the letter "P". The channel is installed legs down, its flat side should be flush with the ground.

- Concreting. When everything is ready, the ditch with the supporting beam is poured with concrete. It is important to control that elements do not move in space. The beam must be in a horizontal plane. If you do not comply with this condition, the movement of the leaves on the rollers will be complicated.

- When the support beam froze, proceed to the formation of the side support pillars. They are needed to optimize the work of the emerging structure. They are mounted closers, support rollers, motion sensors and other auxiliary attributes. Many experts recommend making decorative fence posts first, and then attaching the rest of the parts to them.

As for armored gates or structures made of sandwich panels, they are not installed on the street. These systems are attached directly to the frame of the building, which acts as supports.

Some modifications are equipped with a metal frame, which is easy to mount, even at the factory.

Installation

Before you install the gate, they should be assembled. The most simple in assembly are swing and retractable systems. Consideration should be given to the technology of construction and installation of swing type structures.

It can be divided into several stages:

- Mounting frame. The flap can be made of wood or metal. The latter option is preferable, as the metal is more durable and durable. Initially, the profile tubes are cut into blanks, which when folded should form a rectangle. The corners of the elements are interconnected by welding.To strengthen the product, metal corners are welded to the joints, giving stiffness.

- Sheathing When the frame is ready, it is sheathed with a profiled sheet, tree or mesh Rabitz. If you want to get a beautiful and unusual design, then you can use forging elements as a decor. They require experience with the metal, because it must be bent, giving a certain shape. If you have no experience, you can purchase ready-made options.

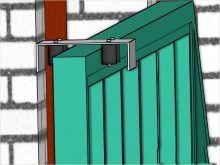

- Mount. Hinged hinges are welded to the finished canvases and supporting posts. It is advisable to do this before laying the stone so that it is possible to combine both halves of the loops perfectly smoothly. If the hinges are welded correctly, then you can simply “put on” the sash on the support pin. At the end of the set locks and gate.

Installation of sliding gates is much more difficult. He assumes performance of such operations:

- The construction of the metal frame. It is made of durable profile tube of great thickness. The length of the canvas is often about 50% longer than the width of the opening. It is necessary to create a kind of counterweight. If the width of the canvas is small, the counterweight can not be done.The technology also involves cutting the metal into blanks with their subsequent welding at the corners, which must be given special attention. Along the entire length of the frame, vertical supports should be welded, to which the sheathing will then be attached.

- Mounting support beam. Outwardly, it resembles a profile tube with a longitudinal slit. The length of the beam is equal to the width of the lower end of the gate. It is attached to it with the help of spot welding.

- Sheathing On top of the frame have sheets of profiled steel. They are fixed with the help of special screws, which are not afraid of moisture and do not damage the metal.

- Installation of rollers and upper guide. Support rolls and attached to a metal platform. It is desirable to fix it by welding on a channel, which acts as a base. The rollers are securely fastened with conventional bolts. The top rail is a small bar that moves along the rolls. Rolls, in turn, are attached to support posts. They do not allow the web to move to the sides when moving. The procedure ends with the installation of removable polypropylene plugs that are attached to the ends of the pipes, preventing moisture or dirt from entering them.

- Gate installation. When all systems are fixed, you should put the cloth on the rollers, test. All operations are desirable to perform at least two of them, as the gate is rather bulky and heavy.

For more information on how to make installation of sliding gates with your own hands, see the following video.

Automation

The frame of many gates is made of metal, which increases its weight. Opening such systems manually is not always comfortable. Solve this problem with the help of automatic drives. It is impossible to make them yourself, as this requires special equipment. Install automatics on rolling shutters, sliding and swing gates. This process can be divided into several successive steps:

- drive mount. It is an engine with gears that drive the entire system into motion. They are located inside a special case that allows you to protect them from external factors. At this stage, the device is adjusted relative to the web so that the rail moves without load.

- Mounting rack. It is fixed on the canvas so that it coincides with the internal gear.It is important to take the product in length with a small margin. When fastening the gate must be completely closed.

- Customization. In order for the engine to move the sliding gates, it is necessary that the teeth on the gear and on the rail coincide. Combine them with special methods, which you can ask experienced masters.

- Connection The engine connects to the electrical network of the house, while using sensors that allow you to open the gate using a telephone or a conventional button.

If automation is used for swing gates, then it is somewhat simpler. Systems based on pumps are applied here. To connect the mechanism, one end should be screwed to the canvas, and the other end to the brick post. After that, the system is connected to the electrical network using various sensors and controllers.

Tips and tricks

Installation of any type of door requires certain skills in working with metal or other similar materials. To get a reliable and durable design, it is advisable to follow a few simple guidelines:

- select only quality materials for the gate. Do not use recycled materials, as they will quickly become unusable,and the gate will lose all the decorative and mechanical properties.

- Before starting work on the project, it is desirable to make detailed drawings. They are needed to properly calculate the load, as well as to select the necessary materials.

- Installation of electric drives is desirable to trust experienced professionals. Do it yourself only if you are sure that you can fully understand all the nuances.

- Purchase roller systems only in specialized stores. They can issue a guarantee for the operation of this mechanism in order in case of a malfunction to replace it with a new element.

Beautiful examples

Although it is not so easy to build a gate, it is possible for craftsmen with golden hands. They often give their products a special highlight:

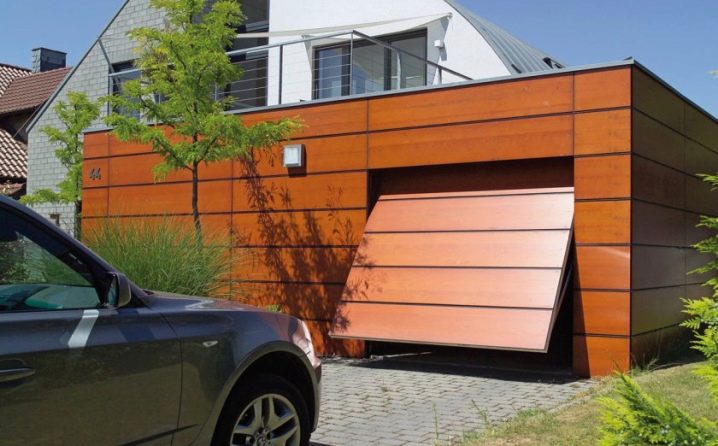

- Here is an example of an automatic lifting gate in a garage. The task of the master was to select the appropriate material for the canvas and reliable automation. He succeeded in both. The gate turned out beautiful and comfortable to use.

- This forged gate for large arches is a work of art. They are made according to an individual sketch by an experienced master, therefore, are presented in a single copy.The gates really adorn home ownership.

- A simpler option - the gate of the boards. They look simple but stylish, especially when combined with a fence made of natural stone.

- The owner of this site made a convenient folding gate-accordion of corrugated. It turned out an inexpensive and original version.

- In this picture - a great option practical suspension model, which is also called hanging. The gates are matched to the style and color of the house, so the whole ensemble looks beautiful.