Gate hinges: views and mounting

Gate loops are a device made of metal, thanks to which the gate is fixed on racks. And, accordingly, the quality and reliability of the entire structure, as well as its service life, directly depend on them.

Special features

Speaking about the design of the gate, we can not forget even about the little things, especially about such an important component as hinges. One of the main properties of the hinges is their ability to turn even with the most weighty sash, while not forcing the owner to make great efforts, protecting the gate from jamming and similar problem situations. Therefore, the choice and process of welding loops requires special attention.

So, loops can be described as:

- The power element, whose main task is to take all the severity of the valves on themselves. On this basis, the hinges must have sufficient strength;

- Parsed item When the construction is fully assembled, it is worthwhile to make sure that when the gate is closed, the removal of the hinges will not occur and the crackers will not be able to disassemble them.

Features of operation and operation of the loops:

- Mandatory presence of special holes for lubrication. The mobility of the parts depends on the proper care, so they need to be lubricated regularly, even in the winter season;

- The hinge radius directly depends on the hinges. Therefore, they need to accurately and correctly welded. Before welding these elements, you need to attach them to different platforms, draw up a peculiar drawing and make sure that the flaps open without problems;

- Particular attention should be paid to the position of the hinges, if they are supposed to be fixed inside the sash. It is very important that it opens well and does not seize.

Species

According to the GOST standard, loops are divided into:

- Cylindrical bearing bearing (or with eccentric);

- Cylindrical, having a reinforced structure;

- Cross-cutting;

- Hidden;

- Three-section overhead.

Cylindrical are equipped with a ball, or, in a different way, a bearing. They are well suited for installation of light standardized gates. But it is worth remembering that the load on all the loops should be no more than 400 kg. This is the maximum weight held. It needs to be clarified at the time of purchase, as it is different for each type of loops. Therefore, it is important to know this indicator.

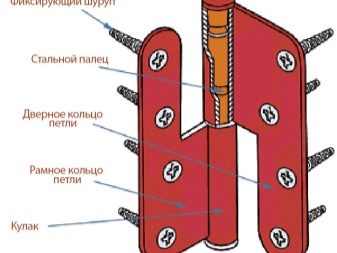

They are standard in both shape and appearance. and look like a two-part cylinder. Accordingly, on one part is located the pin, which is inserted into the second part. However, hinges with bearings are also equipped with a ball. This ball is located in the second part, which is inserted into the pin.

The ball ensures smoother operation with a large load. In addition, there is often a special hole in the opposite side of the bearing that closes with a plug. If necessary, it is removed and lubricated design. Also sometimes there are models when the bearing is located in the middle and the two parts glide over the ball, providing easy opening and closing of the valves.The downside is the difficulty in lubrication, as you have to slightly raise the sash.

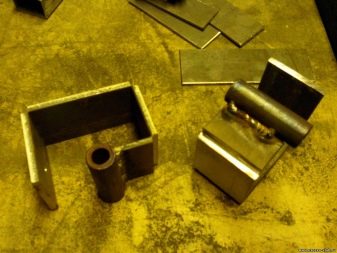

Cylindrical reinforced (with wings) loops withstand a large load, reaching up to 600 kg. They can be distinguished from ordinary cylindrical by their appearance and the presence of additional parts (fastening plates). This allows you to take the frame, sash and gate supports weight of the whole structure evenly. They are fastened by welding or screwed with screws and provide opening in two directions.

They are made of a more durable metal and therefore are able to withstand a greater load. In addition, the wall with the rod is thicker than usual, because of their increased carrying capacity. Bearings in such models are always marked.

Through (mounted) fasteners are suitable in the event that it is not possible to provide welding or screw fasteners. To attach them, you have to drill the support column of the gate and use screws or nuts. However, the loops are distinguished by a small mass of the maximum retained weight, reaching only 200 kg. There are right and left. They can equip canopies.

Through loops have a rod that passes through. The simplest designs are divided into three main elements: a pin to connect the two halves, and two loops. In more complex versions of the elements may be much more. To protect the pin from being taken out from below, install (weld or fasten) the cap. If it is not there, then a special limiter is welded on top of the pin.

Laid on three-section (magnetic) fastenings are advisable if the sash is very heavy.

They are suitable for fences and are different:

- High wear resistance and reliability;

- It does not allow the canvas to sag, as they take on almost the entire load;

- Easily and without noise open and slam;

- The most protected from hacking of all kinds.

They can be confused with end-to-end, but they belong to the cylindrical. In the middle there are two pins that look in different directions from each other. On both sides, empty bearings are attached to them and welded.

These loops literally passed the test of time, since for the first time this design was created many hundreds of years ago. Nowadays, they attract attention due to their unusual and cute design.Happen any form, are carried out in the form of different figures. Most advantageously combined with doors of wood and metal.

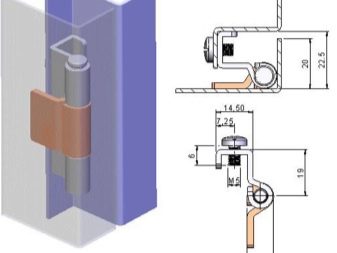

Hidden hinges with the gate closed is not visible. They are in the frame of the leaf and are welded from the inside to the frame and to the transverse side of the pillars. They are extremely difficult to find and even more hack.

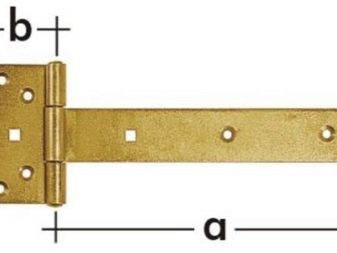

Loops-arrows are hinged and hemispherical and are suitable for fairly weighty and overall gate.

They can be:

- Ordinary;

- Figured;

- Removable.

Adjustable hinges easily allow you to change the height of the sash. They are very convenient if it is planned to shift the support legs. The maximum load on them reaches 200 kg.

Loop differences in shape:

- Cylindrical. The hinge is very tight on any gate. They have a rounded shape and easily turn around without touching anything;

- Square. The form is quite specific, so for installation requires a small indent from the frame. They are fixed more reliably, little visible on the canvas, have an attractive appearance;

- Hexagon. Looks like a square model. They are fixed approximately between cylindrical and square, that is, they are universal;

- Teardrop. Suitable for wooden and metal gates.They are very stable and are highly durable. And, everything else, quite attractive in appearance.

How to choose?

Wickets and gates can be made of wood, sheet steel, corrugated or other trim panels. The mounting of the hinges is also different. Welded hinges are characteristic for metal structures; they are also fixed with bolts and self-tapping screws (for metal). For the gates of wood is characterized by fixing screws.

On this basis, when choosing, it is necessary to focus on the canvas from which the gate is made, its dimensions and weight. For example, if the fasteners are designed for a weight of 200 kg, and the canvas is large and heavy, then they will quickly break. Therefore, it is sometimes necessary to install special reinforced hinges for heavy gates.

Equally important is the location of the loops. The most common hidden and internal.

Loops should perform the following functions:

- Ensure silent opening;

- The retention of the web - in no case should it sag;

- The hinges should turn easily;

- Long service life;

- Resistance to cracking;

- Gate opening width.

The best option is a device equipped with a ball and a thrust bearing. This model has many qualities and is durable. Adjustable models are also very good, as they are very comfortable. And finally, the choice of loops may depend entirely on the aesthetic side of the part. For example, the design of antique loops, inlay with thread or some element of forging.

Sometimes there may be questions about the difference in hinges for the gate and for the gate. In fact, they do not differ from each other, because they are selected for the gate by the same criteria and must perform the same functions as the gate.

How to install?

Based on the size, weight of the valves and the construction of the hinges themselves, the portal leaf can be hung on two, three, and even four hinges.

Installation of loops is carried out in two main ways:

- Bolts or screws. Used for mounting small-sized structures with a small weight;

- By welding It is used for large, massive gates (for example, three-meter fences).

For those who installed interroom doors at home, it will be quite simple to attach the hinges with self-tapping screws.After all, both of these methods are similar to each other. Loops are attached to the front area of the valves and the support post. In this case, they become a kind of decor element of the whole structure and are suitable for both wood and metal.

How to weld?

Hinges with an open location, it is better to cook one opposite the other. This is done with the aim of resistance to hacking. If the loops are hooked from below, they will still not be able to be removed.

Required equipment and parts:

- Selected loops;

- Mounting plates;

- Bulgarian with electrodes;

- Hammer;

- Personal protective equipment: protective gloves, mask and clothing.

Sequencing:

- We take the design and place it on a flat surface. We outline the places where the fasteners will be located;

- The loops themselves are greased with grease;

- Take the sash and put it on a plumb upright;

- With the help of spot welding, we seize two parts of the loop;

- Check the location of the axis of the loop;

- We catch the upper loop;

- Check the presence of gaps and cracks, the quality of the stroke of the valves;

- Weld all final;

- We clean the place of cooking, using a grinder, and paint it.

During welding, it is necessary to control the passage of current so that tacks do not form in the loops. The process itself is best done in a criss-cross pattern to compensate for the welded deformations.

Useful tips when welding loops:

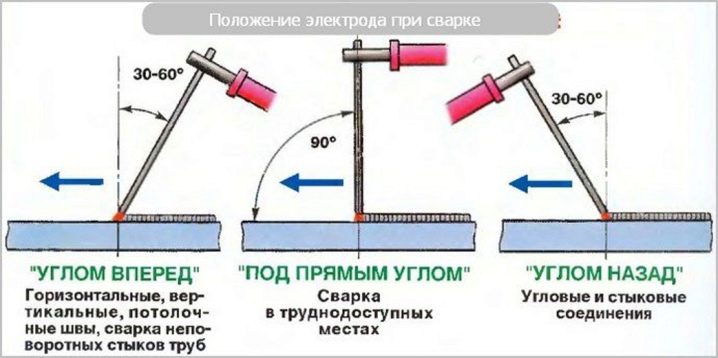

- For straight loops, it is better to choose a horizontal welding position;

- Before starting work, we take the substrate and put it under the sash, more precisely, under its lower region. The size of the substrate should be approximately ½ of the loop. The upper area of the leaf should be held with the transverse edge of the hand;

- In order to evenly distribute the mass on the hinges, additional metal mounting plates can be welded to them;

- To round-shaped pillars make a 5 mm outer release. The rectangular-shaped columns are fixed at the same level with the transverse edge of the support;

- It is more expedient to weld the hinges twice from all sides in turn with small tacks;

- We put a wooden block to the hinges. With it, you can align them, and only then weld;

- Before internal welding, you need to check how smoothly the flaps go. If the movements are like jerks, then we do a few more stickings outside;

- Before you finally weld the hinges, you need to close the sash and put a substrate under them. Thus, the fabric will not sag and welding will be correct;

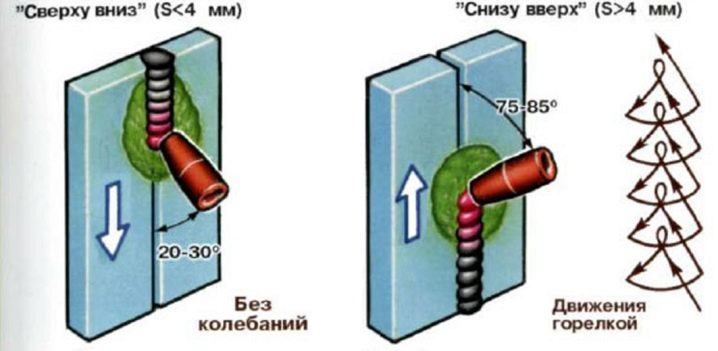

- The weld seam goes upwards;

- Until the weld seams are completely cooled, the gate cannot be opened;

- Hidden attachments should be installed by a professional.

Gate from a professional flooring:

- It is necessary to make jumpers parallel to the vertical side of the flaps;

- The lintels need to be fixed where the hinges will be welded. It should be that the shutters are divided into three areas;

- After fix to the loop jumpers;

- Disguise lintel tracks and the welding area can be small pieces of corrugated.

Personal Security Rules:

- It is important to ensure that the welding machine is functioning properly;

- You can start cooking only on a completely dry surface;

- Work items must be clean, free from contamination by flammable substances, such as gasoline or oil;

- If parts are subjected to pressure, they cannot be boiled;

- Under no circumstances should a rag moistened with flammable substances or stained with them be placed on a gas cylinder. This may cause a fire.

What to do if rusted?

To iron loops served for a long time and without any hitches, you need to take care of them. Paint with paint to avoid corrosion. Every three months they need to be treated with grease so that the metal does not deform.

Rapid wear of parts in most cases occurs due to the fact that the load is distributed unevenly. If they are correctly welded, the load is distributed evenly and the axes are strictly followed, then the problem lies in the poor quality of the fasteners.

To prevent abrasion and corrosive processes, elements should be lubricated and occasionally inspected. In some cases, minor repairs will be needed.

The best option is to remove the loop and clean off rust, old grease and dirt. This can be done with the help of small skins. Using a paste for grinding, rub the pivot shaft and remove the excess with a solvent. After the loop hole, clean and lubricate abundantly, for example, with grease. So that metal parts are not frozen, the work should be done only in the warm season.

Successful examples and options

As mentioned earlier, the choice of hinges depends on the gate.For large, heavy and high gates (for example, three-meter), reinforced and three-section hinges are better suited.

For decoration of the gate in the old style, you can pick up decorative forged hinges, which can be beautifully shaped.

For easy gates and gates fit hidden fasteners that will not be evident.

How to weld hinges, hinges on the gate, see the following video.