Beautiful wrought iron gate in landscape design

The gate must be not only strong, but also beautiful. However, there are few designs that would gracefully be compared with forged products. To apply them correctly, in accordance with the principles of landscape design, is the only way to create a beautiful, elegant environment in your backyard.

Special features

Forged gates harmoniously combine such valuable properties as high security and external beauty. The widest range of patterns allows you to make the "protective shell" of the site individual and few people remain indifferent. Moreover, such a fence itself testifies to the wealth and excellent taste of the owner of the land. The problem is different: forging cannot be cheap by definition. And therefore, if you want to use it, you should try to make decorative designs yourself.

Keep in mind that forged products are quite heavyweight and require durable retaining structures.

Even if only one gate is used, their weight is still significant and strongly presses against the supports. Pay attention to whether the security of the territory next to the house is secured, whether the construction is original, whether it conforms to the requirements of landscape design.

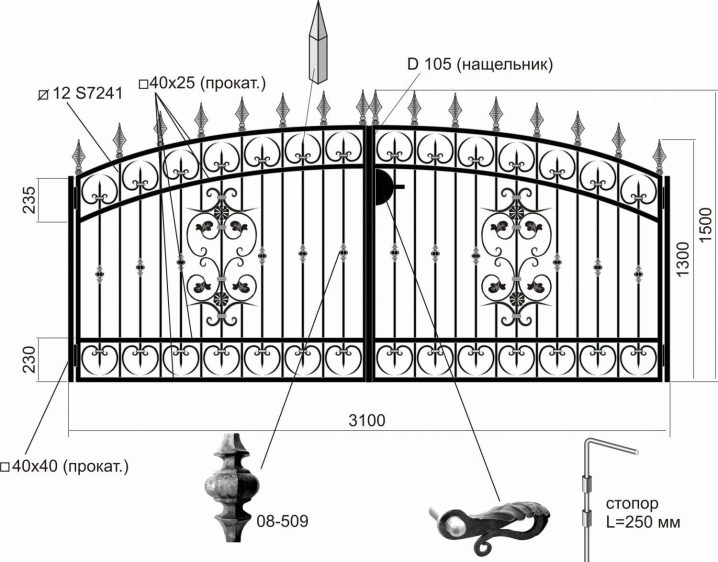

To prevent the appearance of errors help sketches, which reflect necessarily:

- frame (the shape of the whole product and rigidity depend on it);

- fasteners;

- canopies;

- decorative details;

- locking devices.

For any of these components the exact dimensions must be indicated. Also, the geometric shape of the leaflets is chosen in advance. Designing involves taking into account the location of stiffeners, gaps between them, methods of attachment to the fence. If it is intended to install the gate, its location is also marked. Drawing up more detailed schemes for conventional gates is important because a large mass of forged products increases the risk of error and also increases its danger.

Manufacturing technology

Instructions on how to make forged gates step by step with dimensions are not limited to drawing up sketches and drawings.

It is recommended to take:

- sheet steel no more than 0.1 cm thick;

- peaks;

- twisted rods, which are made of metal with a thickness of 0.5 cm and a shaped tube with four edges (the largest cross section - 0.14 cm).

If you use a thinner steel, it will look bad and unreliable. Applying a thicker material will have to turn to professionals, since it is unlikely that you have the necessary equipment and equipment for it.

As for the quantity, after preliminary calculation it is desirable to increase it, leaving a reserve of 30-40%, then you will not encounter problems if something goes wrong.

Intending to create a blind gate, immediately pick up the material that will fill the sash, also calculate the need for it. After collecting the raw materials and preparing the necessary tools, proceed to work.

Forging can be cold or hot.

When processing the second method, the metal is heated until it becomes soft, and they begin to give the product the desired configuration. At the same time do not forget that bending and cutting elements will lead to an increase in their size.

It is safer to forge a cold metal, bending it with the application of strong pressure, but you will have to spend no less energy. If you do not want to do the preparatory work, you should buy ready-to-use kits - their choice is large enough and will satisfy almost all needs.

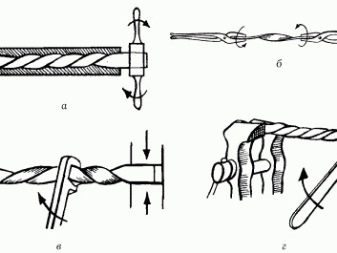

One way or another, when the forged parts are ready, they need to be welded. Initially clearing the site where they will work. Of course, everything that can burn is removed from there and warn your household. A number of channels, the dimensions of which are 0.2 m smaller than the workpiece itself, are laid on leveled ground or a welding table. The surface is required 200 cm longer than these parts.

Be sure to check this surface and the layout of channels on it, using a hydraulic level. If you need to make a broken contour or radius surface, cut a rack of that size, which is indicated by the drawing.

The accuracy of geometric shapes is verified by measuring the diagonal distances with nylon threads. Having found a discrepancy in their length, immediately eliminate it and then continue the work.The item is placed on the welding table, once again convinced of the equality of the angles between themselves, and firmly welded joints.

The bottom of the gate is always made with a right angle. If welds have appeared during welding (and it is almost impossible to avoid them), you should clean these defects with a grinder with a special disc. A broken edge begins to create, drawing a line on the sheet and cutting exactly along it. For cutting along the lines and in other necessary cases, use a power fret saw.

After the cut, the prepared block is combined with the sheet, connected by a welding semiautomatic device. The remains are attached to each other clamps, weld and wait for natural cooling. To get a radial element, make a couple of blanks, put a sash on top of the steel sheet and grab it by welding. Measure the bar going up (increasing by about 1/3 in comparison with the measurement for greater reliability) and cut off a piece. One of the sides is tied to rigid holders and bent. Thus, the required radius of the structure.

To make an element with a radius, the diameter of the part must exceed the dimensions of the profile. The same steps are repeated with the following blanks.The radii are placed on the upper lobes of the valves, cut off the edges and welded. Be sure to look before applying current to the electrode or acetylene in the hose, whether the fasteners are correct, whether there is any surplus. When the product cools, it is brought to perfection with the help of LBM.

Note: if the radius is very large, it is not recommended to receive it by the bending method.

It is better to use the template, increasing it by 1/3, and cut the metal from the right side, after which, holding the workpiece, slightly bend the opposite edge. Carefully approach the formation of the bar and the peak, because these details of the forging gate are the most colorful and aesthetically pleasing: this is what all experts believe.

Twisted rods are made of quadrangular blocks, heated in the furnace and turned after clamping as much as you want to get twists. The semifinished product necessarily ripens. Peaks are made harder. The first step is cutting the squares of steel sheets, correcting its geometry using grinding machines. The product is brought to a white tone, a stencil is flattened with a hammer.

The sharp stripes always quench, bringing to cool in the winter or spilling in summer.Then the product is examined, and the uneven irregularities are grinded. Having made a complete set of a rod and a peak, once again compare them with each other, so that all the details fit together, and proceed to the final welding.

If you prefer to use ready-made elements, rather than do them yourself, you still need to cook the frame; the required thickness of the steel sheet can reach 1.5 cm. How many exactly - depends on the complexity of the gate design: the more sophisticated they are, the more metal will be needed. It is also necessary to increase the thickness when an iron sheet is welded to one side.

The pipe from the profile is cut, from time to time it is turned, carefully making sure that the geometry of the corners is not disturbed. At first, all the details are welded on flat surfaces, otherwise the structure may twist. The frame is checked to eliminate the appearance of distortions, then the welds are welded with an inverter. Using a welding machine, a lock and a handle are attached to the resulting frame, and then the metal surface is treated with a grinding machine. If it is planned to make a blind gate, insert the metal sheets into the frame and fasten it by welding inside.

Now take the inverter and weld the decorative elements on the front side of the frame, making sure that they are symmetrical on all the doors.

Be sure to grind the resulting thing in the open areas with angle grinders, and in the narrow - sandpaper will help.

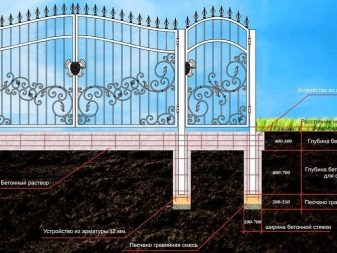

When the gate is forged and welded, it is necessary to make the supports stronger. It is best to use steel pipes lined with bricks. The posts are supposed to be buried 0, 7-1 m (so that they are below the level of frost penetration), and the width of the notch should exceed the diameter of the pipe (at most) by 0.1 m. Perpendicularly inserted pipes are covered with a layer of rubble and reinforced with cement.

When the cement hardens, the tires need to be welded to the pipes (width is 60-70 mm each, and the heaviest structures require the use of 3 tires per door). Then put a brick so that each next seam overlaps previous ones.

Be sure to need a trowel. Having completed the laying, the hinges are welded to the doors in accordance with the way of fastening the supports. From below, a pair of loops is boiled in one direction, and from above they are welded in the opposite direction.This approach eliminates the removal of the gate by unauthorized people. Be sure to arrange a full check, if somewhere the mechanism sticks, the body is skewed, then these defects must be eliminated immediately.

Finishing of wrought iron gates is most often carried out by dyeing compositions with a matte look.

The metal is cleaned with a grinding machine (even the gate just made or assembled from finished components does not relieve this duty), then it is primed and treated with anti-corrosion agents.

Kinds

A detailed description of the manufacturing technology (assembly) forged gates is very important, but no less significant is that they come in various forms. So, swing openwork constructions can open inside or outside the yard area. All depending on where there is more space. It is recommended to use the opening inward so as not to interfere with traffic and people walking. However, if your house is separate or located at the very end of the street, this consideration does not matter.

Products with a professional sheet differ in universality as the strongest steel goes on their production.As a result of processing by rolling equipment, the surface is covered with trapezoidal relief - it is not only beautiful, but also much more reliable than a smooth metal. Professional sheet is most often produced with enamel coatings. This material does not corrode a little and can be moved to another place if such a need arises.

The professional flooring is fastened to the forged gates with self-tapping screws, and fixing corners are welded in advance for their screwing in. Many enterprises and even private masters are offered ready-made kits with professional sheets (both removable and fully welded).

Exclusive in appearance of the product allows you to receive such a method as cold forging. The problem is that it requires special equipment and is expensive. Such methods are suitable only for large enterprises and organizations, and small workshops are engaged only in hot forging. Cold bend rod gives it increased strength compared with the usual state.

Geometrically and technologically complex elements, artistic decorations can be created only on special machines.

Self-made cold method gates are unprofitable.Together with them you should immediately prepare the gate, fences, entrance groups. Or sell forged items permanently to order. If both ways do not suit you, it is more profitable to buy ready-made blocks and just apply them.

Any types of forged gates, including sliding gates, can be created by hot forging. However, it will not be possible to save money on equipment; moreover, you can use it yourself only if all precautions are taken. Be sure to keep in stock running water to cool the heated metal. Using a gas torch, you can heat a rod with a diameter of up to 1.4 cm, and instead of an anvil, an inverted rail will do. Such tools are sufficient for obtaining large design details.

Sliding wrought-iron gates are divided into three main subtypes:

- rail;

- cantilevered;

- suspended

A definite advantage is that neither on the street nor in the courtyard will not need extra space. Even very heavy constructions do without loops, and the load is distributed evenly. You can open and close the entrance smoothly. In the case of suspended and cantilever gates, less need to clean the snow in winter, and the console and rails allow cars to enter any height.

The weak side of the sliding gates is that additional space will be required for the web to move, and this place is only along the fence.

The manufacture of almost all types of forged gates necessarily requires the use of welding. But not all parts are metal, often create products with polycarbonate. Using this material allows you to inexpensively create a magnificent-looking gate; while the protective properties are quite satisfactory. Polycarbonate serves for a long time, but it is necessary to carefully select it according to the level of light transmission. Painted entrance structures can be in a variety of colors, if only they are in harmony with the surrounding elements and the house itself.

Polycarbonate structures are not only simple in installation, but do not light up, are mechanically strong, can be combined with other materials and operated in various temperature conditions. If you want maximum naturalness and naturalness, you need to choose solutions with wood. Often clapboard fill the frame. You can use wood for all the doors as a whole, and for the gate separately.

Double-wing wrought-iron gates are better than single-wing ones in that there is no need to open them completely once more. When people go in or out of the yard, that's enough. It is important that the variants with a single flap have a large mass, and therefore create an increased load on the bearing elements.

Automatic forged gates are good not only because they facilitate everyday life and increase security. This is an interesting way to highlight your commitment to modern technology. Additional security features include photocells, magnetic locks.

Style and decor

Dealing with the technical features of wrought iron gates and their different types can be very long. But it is equally important to find out the details of their appearance. Note that forged fences are perfectly combined with evroshtaketnikom. But note that the elements cut from the profiled sheet do not look very presentable, they easily lose their paint. It is more correct to choose products whose edges are rounded, as it looks much nicer.

In order for your appearance to meet your expectations, there is only one way - to follow the recommendations developed by specialists.Their performance allows to achieve excellent results even for not very experienced people. Look, first of all, not at the drawing, but at the cost of the project you like. The most expensive are the blind gates, complemented by a complex ornament, and even made in an atypical geometric form.

If elite fences are unavailable to you for financial reasons, you should prefer options based on sheeting or metal pipes.

Professionals caution, even with sufficient funds, from overly elaborate decorations. This not only can create a sense of bad taste, but can also impair the functionality of the finished gate. Even fairly widespread drawings with lions are not always appropriate. Sometimes it is worthwhile to leave the canvases simply painted in a certain color and not engage in other experiments.

The selection of the appearance is clearly tied to the concept in accordance with which the house and yard are made. Keep this in mind when drawing up the door drawings. It is considered undesirable to reject the style of the garage and entrance gates, because this immediately creates a contradictory and strange feeling.It is also important to immediately determine the performance of the entrance group as a whole. It may contain deaf elements, may be made in the form of a lattice, and there are still combinations of these options among themselves.

An impenetrable barrier is suitable for those who dislike even the thought of violating the privacy secrets. In addition, these types of structures facilitate maintenance and increase safety. It makes no sense to choose deaf samples if your fence is low or made of mesh. The level of protection when using openwork gratings is not much lower, besides, the thin construction will be much cheaper, because its production requires much less metal consumption.

The windage of solid wrought-iron gates is excessively large, and no mass of them gives a guarantee that the fence will stand in strong winds. Blown through grates are much safer in this regard. If you can not figure out which considerations are your priority, choose a mixed type of fence. Most often, a solid strip in it goes from the bottom or in the middle.

For your information: its lower location makes it difficult to penetrate inside the small flightless animals, and the middle one is more stable from the wind and better covers what is happening in the yard.

The design of the sliding gates is very stingy, since any embossed protrusions will prevent you from using the gates fully and will not allow them to close. The classic style is the most common, especially as for the gate it combines a number of areas. These are not only ancient Gothic solutions, but also Baroque, for example. A key feature of the classics - the simultaneous embodiment of rigor and elegance. Often there is a coloring imitating bronze or gold, plant, leaf and fruit ornaments, as well as simple lines.

Classic gates always seem to rush to a height. At the same time, the idea of good quality and inviolability of the fence is invariably carried out. Baroque immediately stands out with festivity and an abundance of artsy elements, volumetric details.

More modern approaches, such as modern or high-tech, have their own characteristics. Thus, modernist welded doors do not have pronounced symmetry, chaotic patterns and lines, giving a smooth bend, are preferable. The furnishings of country houses and country houses are better suited to the style of the country, which requires filling the frame with wooden elements.

But remember that wood is less reliable and requires more intensive care than metal.

It so happens that you can neither choose a style nor understand whether a dragon or another drawn character is suitable as a decoration. Then it is more correct to turn to specialists. They can be considered as designers and architects.

Installation and Care Tips

The installation of the gate to the courtyard of a private house is considered to be done according to all the rules only when using pipes with a cross section of 10 cm in diameter. For the preparation of a fixing solution take 25% of cement and 75% of sand (by weight in the dry mix). Do not weld the grid on the frame tightly, because a small gap will only improve the perception. Remove excess anti-corrosion agent with a soft cloth. It is recommended to put the gate and fences at the same time.

Swinging type is most often made from a pair of shutters, whose height is 160-180 cm. If you want trucks to enter and leave, the width of the passage should be 320-350 cm. It is enough for light vehicles and 260 cm. .

Relatively light gates are suspended at two nodes, and heavier at three.

Typical width of the gates - 1 m.Her style should reproduce the overall appearance of the gate. When it is necessary to deepen the pillars into springy soil, below the freezing point, a frame in the form of a letter P is cast from concrete. A pipe should be welded to the fixture located inside the frame. Only such a scheme will prevent premature destruction and deformation. Gate clearance is usually 50 mm, and if you increase it to 100-150 mm, they will easily open even after heavy snowfall.

Doing your own hands implies rubbing with a damp sponge, treatment with aerosol preparations and napkins with special impregnation. Corrosion protection must be updated at least once in 4 years.

Locking mechanisms need to be lubricated as needed, as soon as they start to make noise, or move too tight.

Beautiful examples

To find out which option to choose after all, and which gate is right for you, we recommend looking at the following photos. Even if there is no ideal option, they can still be a good incentive to search.

Here is an unusual, truly original gate. The middle of them is filled with a unique lattice pattern,and the sides are made of solid metal. Although everything is tinged with a single tone, it does not seem to be somehow overly gloomy, it does not create bad emotions.

The two-color solution is also very attractive: the larger external rectangles are iron, and the internal shapes inscribed in them imitate natural wood. Artistic forging looks impressive on the above photo: straight lines of the peak vary in height, end with tips looking in one direction, and the main part of the grid is decorated with curls.

But street wrought iron gates do not have to be dark. For example, it looks like white fences, divided into three tiers in height. Each tier is decorated with decorative elements of a special type. But a more voluminous solution, in which the outer bands of white are harmoniously combined with a rich blue background.

Wood inserts can be the most abundant, even eclipsed outwardly metal parts of the structure. Here four vertical posts are made of metal, top, bottom, and a figured array above the main part of the structure. Everything else is made of moderately dark wood.

In the courtyard emphasize the external attractiveness of the gate and create with them a harmonious ensemble capable of railings. Here, for example, they are refined black in color, which, by the principle of contrast, is combined with the white color of the steps. Together with the unsaturated reddish tone of the porch bricks, the exterior looks even better.

Rounding out our acquaintance with forged designs of antique gates. This includes bivalve constructions with wooden filling, a symbolic image of the sun, inserted into an ordinary wooden block, and many other options.

The final decision, of course, to take you and only you. But now, having understood the features of choice and installation, having familiarized with the basic principles of gate design - it will be easier to make it!

How to make a wrought iron gate with your own hands, see below.