How to make garden paths with your own hands?

The formation of garden paths can occur in a variety of ways. But only knowing the specific features of each of them, you will be able to avoid mistakes. Even referring to professionals, it is useful to know which steps are necessary and justified, and which ones represent only an extra expenditure of funds and forces.

Special features

Gardens, gardens, cottages for many people are no less important than city apartments or private houses. But in order for worries and anxieties to leave you, you need to take care of the infrastructure of your possessions. Their arrangement cannot be considered complete if the garden path is not prepared properly.

Everyone can create and arrange it with their own hands using the most sophisticated materials and even simply old unnecessary things.Due to this, significant savings are achieved, and an attractive element of decor appears on the site. It is important to note that the garden path is a small, carefully decorated path that allows one person to move freely. As a result, it is not necessary to spend extra building materials on its construction.

How to do?

Before you make a final decision in favor of a particular material, you need to evaluate all of its characteristics, not only positive, but also negative. There are a lot of offers how to make garden paths cheap and beautiful, but you should take into account that they are realizable only in a small area. When you want to build a wide and long path, you can forget about saving.

The cheapness of the materials at hand also has a downside - they serve too little, since the whole structure for the most part is placed directly on the ground.

The creation of a cement pad, although it increases durability, leads to additional costs.

Be sure to take care of stylistic fit. tracks to the surrounding space.If you do not agree on it, do not fit harmoniously into the garden ensemble as a whole, no amount of effort expended will justify the created bad taste.

As far as possible, avoid a combination of dissimilar materials, because the slightest discrepancy between their properties can lead to the appearance of an ugly-looking structure.

Therefore, it is worth analyzing the properties of individual materials and specific versions.

It is important to choose not only simple ways of preparing the tracks, but also those that will be reliable and convenient, guarantee safe movement exactly on your site. Even low-cost materials should be evaluated for their resistance to corrosion and decay, the appearance of mold colonies, resistance to frost, heat and moisture. Consider whether it will be easy to repair the track covering, whether it will withstand the load that is being created.

A trail used rarely can be covered with gravel, sand, or gravel. But it is desirable to elevate the passages between the beds in the country, because it is unlikely someone will like to walk on the dusty or muddy ground. Places where you will move constantly, it is recommended to pave with strong materials or make a monolithic layer.

If a car (motorcycle) will leave the track at least occasionally, the choice is small - in this case, concrete bases are used, paving stones are put.

In addition to practical qualities, the compatibility of the material with the dominant of any garden, backyard area - a residential house is very significant. It is advisable when installing the track with your own hands or with the help of professionals to choose the same material that is used to cover the facade. Pay attention to the relief of the territory - it happens that it is difficult to lay a certain material on a slope (ascent) or to lead a path from it along a curved path.

If possible, stay away from any tree, large bush; the root system eventually destroys any strong breeds of any kind and can cause a lot of trouble.

Avoid placing the tracks where water may accumulate when the snow melts or if it rains.

An important role is played not only by the right choice of material and track, but also by preparing its base, especially when using gravel and rubble. So that these materials do not crumble, do not move anywhere, use geogrids.The pebbles located in the cells will nowhere move, they cannot get lost, they cannot walk or ride a car, the bicycle will be much easier. In this case, specially selected material eliminates the germination of weeds, the accumulation of rain and melt water.

Geofabric of which the lattice consists can be used without the help of professionals. In composition, it can be very different, for example, a polyester fabric is environmentally safe, polypropylene is characterized by increased strength, is completely unaffected by the formation of mold colonies. Multicomponent coating in rolls is cheap, but at the same time its service life and reliability are not long enough compared to other options.

Geotextiles, released in the Russian Federation, by a number of practical indicators have bypassed far foreign counterparts, while it costs significantly less.

Now that the base is fully prepared, it is time to characterize the main types of garden paths.

Wood

Wood is an almost universal material, suitable for any type of work and organically combined with gardens of various types. The undoubted advantage will be the fact that the tree allows you to realize your plan very flexibly, to form exactly the structure that you want to do.

Most often, garden paths are built from planks, the width of which is chosen according to the width of the created structure. You can put them both close to each other, and with a gap of 5-10 cm, which allows you to save some material and create an original appearance.

It is recommended to lay the boards on the rubble. This solution provides a long service track. In order to increase its reliability, it is worthwhile to somewhat deepen the base material into the rubble layer, thereby reducing the risk of operational deformation.

Structures of wood cuts can be a good alternative to the plank, but you need to carefully evaluate the compatibility with the rest of the details on the site. Think about what kind of wood to choose, how to choose the original color and its appearance. The diameter of the log house is also of considerable importance for creating an elegant walkway.

Solid (unbroken) path is also formed on the lining of rubble or other bulk material, necessarily processed with sandpaper to perfect smoothness.

No matter what type of wood you use, you will always need to treat it with paint or varnish, otherwise there can be no talk about long service.

Of tires

If you don’t want to spend money on boards or a wooden blockhouse, you can use various materials that you don’t need in your household. Judging by the practice of a large number of people, practically everything that does not fail for a long time is suitable. It is easy to make a track out of old tires: you will need to cut them and put them along the intended path; necessarily need to form a frame of the boards. Despite the small attractiveness, such a track device will definitely serve for several years.

The advantage of using tires for the garden is that the rubber, even after the expiration date, is not susceptible to overcooling, overheating, precipitation, and even outwardly it does not change.

All care can be reduced to the removal of debris and its periodic flushing out of the hose. The master class will allow you to master two basic approaches to the use of tires: in finished form or in the form of rubber tiles, resulting from the processing of car tires. On uneven plots, it is advisable to use such a technique as a footpath in the “ladder” format.

Usually tires are flatly placed on the ground, moving from lowlands to elevated places of the plot; The tire will be stable if it is buried and filled in the middle with primer.You can avoid slipping in bad weather by spraying the track with a gravel layer.

From cement

It is most correct to build country cement paths in the autumn, when the harvest was already harvested, annual crops were removed, and perennial crops were covered for the winter season.

Why cement should be chosen, it is easy to understand - this is a significantly cheaper type of material than a design based on paving slabs, especially decorative stones.

Concreting using ready-made forms requires to prepare, besides sand and cement, also water, gravel or crushed stone, small boards, cardboard boxes, adhesive tape or insulating tape, and a manual concrete mixer. The first step will be an accurate choice of the place under the path, which must be leveled, not have differences in height. Before concreting the chosen strip, put a board border, pour the inside with a sand layer mixed with gravel (rubble), level the base.

To prepare the solution, you need to take a cement grade not lower than M200 (however, the M500 is the upper limit, a more durable coating is not needed in practice and will only increase the construction cost in vain). Check for lumps in the powder, and if there is such a need, sift it further.The mixture is formed by 3 parts of sand, 1 part of cement and a little less water. Moisturize it until the solution becomes easy to pour into the mold, but it should not spread.

Always prepare exactly as much cement mortar as you can use in the next 60-90 minutes, otherwise it will turn out to be of the worst quality, and then it will be completely lost. Cementing the garden path without cracking is easiest with ready-made forms. Sometimes you want to trim the wet surface with a spatula. After the solution begins to set, put it in the designated position and move the form further.

No matter how hard you try to do the job qualitatively, the missing places will still remain, since the form does not ideally repeat the track configuration. To compensate for this drawback will help fill your own prepared forms. That's when the cardboard comes in handy, which will have to be cut into strips, bend them in a certain way and put together with insulating tape (duct tape). The blanks are filled with a solution, it is left inside until it is completely cured.

Attention: when making “cobblestones” in this way, try not only to fill in the gaps, but also not to go too far from the configuration of the main part of the coating.

When a block made of concrete dries, the cardboard is carefully removed. Since intervals will still remain between the cobblestones, they need to be filled with cement chips, crushed rubble or other granular material of sufficient strength. Instead of the standard fencing of the boards it is possible to use more unusual types of borders.

For all its merits, concrete garden paths are somewhat inferior to those made of wood concrete.

Mason arbolitovyh blocks has its own characteristics. The connection between them is achieved by a cement-sand mixture in a ratio of 1: 3. Carefully check whether the purchased products do not deviate from the established dimensions, and if there are differences, you will have to increase the masonry joint to 0.8-1.5 cm. Unlike the construction of capital structures, the increased thermal conductivity of the cement joint in comparison with arbolit does not matter.

Ready-to-use adhesive formulations are allowed to be used only in the case when the value of the wood concrete block only slightly differs from the declared one.

It is very important to lay the first row properly, the accuracy of the placement of subsequent blocks depends on it.

You need to work at an air temperature of at least 6 degrees Celsius; the solution is made thicker so that it is better kept on the wood concrete, and after coupling the blocks with it, it is impossible to move them anywhere. The coloring additive will allow to give both the concrete and the wood concrete exactly the desired color.

From bottles

The use of plastic bottles in the design of garden paths is popular because of the simplicity and ease of such a solution. It is very cheap and, moreover, much more durable than the use of tires. A wide range of colors and the absence of their fading over time, the ability to fit tightly into the ground will please most gardeners and gardeners.

Keep in mind, however, that thermal deformation will cause a shift in the bottle series over time and will have to be corrected manually, and quite often.

When applying whole bottles, try to set them in such a way as to prevent spontaneous movement and escape into the ground. Any of them must be filled with sand (gravel), otherwise it will be easy to wrinkle and crack from the slightest load. Under the future path they tear a trench of 1.5 shovels deep, protecting it from all sides with wooden formwork.The substrate is made of rubble, unwanted wood, broken bricks and dry leaves - a similar basis will prevent the track from sagging.

A layer of earth is poured over the improvised foundation, tamped with it, as is an additional sand layer 20-30 mm thick. Only after that it makes sense to put the prepared bottles. Lay them either horizontally, orienting them towards the edge, or vertically - bottom up. It is necessary to walk along the bottle path for even pressing into the sand. Pour a homogeneous mixture of sand with cement into the smallest gaps between the bottles, tamp carefully with the board and pour water over it.

From natural stone

Plastic construction is economical, but still there are more durable and environmentally friendly solutions; An example of this is paving with natural stone. At the same time, natural raw materials far surpass in their aesthetic possibilities even the most sophisticated concrete blocks, bricks, special tiles. Be prepared that you will need to pay a considerable amount in order to pack all the necessary material and even just purchase it. The stone is rather heavy, and in almost every case it is required to order a truck to deliver it to the right place.

The laying technology has been worked out quite well, but an exact calculation of the need for the material is impossible, it will be necessary either to purchase another batch, or to look for alternative ways to use the surplus.

The cost only seems high: with a long period of use less wear than concrete structures, quickly pays for all costs. If you want to do all the work yourself, use sandstone, granite, quartzite, slate or shungite. The granite walkway can work for at least 200 years without external changes. From the concentration of quartz in the composition of this rock depends on its external color.

Slate is not so durable, but it is more convenient for them to pave the ground, because on sale this mineral is always represented by insignificant plates.

Avoid shale varieties with a significant amount of pores.

Quartzite differs from shale products only in the presence of mica, it is stronger, but more difficult to process.

Shungit allows you to make a track that meets the principles of classical or modernist design. The advantages of this mineral are very low abrasion, frost resistance and excellent tolerance of aggressive substances.

In most gardens, the paths are laid out with sandstone.Although it is not as hard as granite, it can still last for decades and is relatively inexpensive.

Now you can talk about how ready blocks are formed. In addition to paving stones (chipped), sawn stone has approximately the same geometric configuration. A wide variation of values and forms characteristic of the cobblestone. Plitnyak is distinguished by the fact that its surface is always flat (hence the name). Processing of the prickly borders of limestone is not performed, its laying is very fast even by non-professionals.

Only decorative paths are made of cobblestones.that look elegant among trees, bushes and grass, but walking on them is extremely difficult. The exact opposite of the cobblestone is sawn stone, which is treated very carefully. It is easy to move along the path made of such material even in high-heeled shoes.

Out of gravel

This option is bad because it is not easy to walk on it in any shoe. It is possible to fill up gravel without concreting the substrate, the only thing that is required is a bed of geotextile, so that weeds do not grow, and the formation of borders.The price of gravel materials fluctuates quite strongly, the decisive role is played by the value of the fraction and brand of the supplier. It should be noted a number of undoubted advantages, which has gravel dumping for a country house.

So, it allows you to use stones of various sizes at the same time, to lay a path directly or along a non-standard path.

Backfill is perfectly combined with wooden, concrete, stone and even metal elements.

In addition to screening, you can use a layer of rubble, make a path of various widths. There is a great variety of decorative elements - these are columns, arched structures, and “islands”. By removing the leaves, weeding the few weeds and leveling the gravel, you can consider the care of the track finished. If you suddenly need to repair the strip, the work will be reduced to adding gravel material or mixing the already used one.

The tracks of gravel are not recommended to be used where many people will go, they are not very suitable for the passage of cars.

Of brick

The undoubted advantage of brick is strength, ensuring the preservation of the characteristics of the material for a number of years, even with constant active exploitation.Among artificial materials, no other will allow to focus so clearly on the stylistic combination with the landscape and the house. If the installation was done strictly according to the technology, it will be necessary to redo the track only when creating a new landscape, with which it will cease to harmonize.

Any owner will be able to build a brick path, using a few simple tools, and subsequent care will be minimal in time and effort. It is undesirable to create tracks already 0.9 m - it will be very inconvenient to walk along such lanes.

In work even a broken brick can be used provided that its appearance corresponds to the surrounding space.

Useful tips

The classic version of the manufacture of garden path is the use of plastic covers. Of course, they will need a lot, and they are externally identical to withstand a certain style. Recommend to prepare the base of the sand. It is necessary to ram it as carefully as possible, then the path will surely serve a couple of years.

An alternative to tires can be considered the use of bat tiles, which remains in abundance after most repairs.It is very important not just to lay it out, but to arrange it so that the surface looks as attractive as possible. Most often they prepare a sandy substrate, and when forming a mosaic they act as creatively as possible. But it is important not to forget about the convenience of using the track and that all its parts should have the same height. The pieces of the tile are necessarily separated by at least a small gap, and after laying they are tied with cement mortar.

Some craftsmen act differently: they start by pouring the necessary strip with cement, after which they start laying the broken tiles. But this method requires the ability to work quickly and with complete certainty with the design of the surface, since there is no time to invent it after preparing the mixture.

From factory materials it is best to use paving slabs, especially since its use does not require significant experience. If desired, such a coating can be made by hand.

Vibrating machines are required for this. On 1 square. m cover need:

- A bucket of cement (grade not lower than А-Ш-400);

- Three times more sand;

- 0.2 kg plasticizer;

- If necessary dye.

It is unlikely to create a spectacular tile without dyes, and their consumption is relatively small, so it’s unwise to save on such reagents. Experts recommend to prepare for work not one, but at least two or three forms for receiving tiles, in order to radically speed up the process. The solution in the forms is compacted with the help of a vibrating table or vibroplatform, and when the blanks acquire the necessary strength, they can be immediately applied.

There is a scheme that does not require compaction, but it involves the use of a large form. Immediately place the container in the selected location, pour the prepared mixture into it, ensuring that no voids appear in the material. It is permissible to combine dyes of various tones, “adjusting” the type of tile to the general perception of the site.

Experts do not advise to get involved in experiments with the addition of stones, broken glass in the absence of adequate engineering knowledge and design experience.

In most cases, tile itself becomes attractive enough to satisfy aesthetic tastes.

If the goal is set to speed up the work process as much as possible, it will be necessary to abandon paving slabs and other materials and use reinforced concrete slabs. All actions will be reduced only to the choice of the necessary places and to laying of plates.The coating is not the most aesthetic, but it is very durable.

Preparing the track, take care of the design of borders. They help to make the border clearer and to avoid the destruction of the coating. Without a border, you can put concrete slabs or natural stone with fancy geometry. But sand, gravel and pebbles necessarily require external fencing.

The highest durability is distinguished by a curb of concrete placed on a concrete base. When choosing material for the track, consider how it fits into the style of the entire plot.

If you prefer a rustic style, it is advisable to draw a path with a tree. It is most correct to create curved structures using natural stone, and a brick will look perfect if there are structures built from it. Fans of original ornaments and patterns should choose paving stones of different colors. Gravel and pebble solutions are optimal in the garden with a pond.

Concrete and brick are combined between themselves. Pebbles with wood, gravel with natural stone can also be combined into an attractive ensemble. Laying gravel and small pebbles requires pretreatment of the soil with herbicides, covering it with plastic wrap or agrofibre. The outer curb is tiled or brick.

If you have chosen a tree, it is recommended to dry the sawn thoroughly and cover the entire surface of the wood with warmed linseed oil twice.

When laying the stone path there is a secret - it is better to choose those stones that have at least one flat face. After filling the voids between the blocks, the path must be watered with water, sometimes it is necessary to sprinkle it with sand a second time to close the remaining gaps.

When laying paving stones, standard technology involves preparing a trench 200 to 250 mm deep. If the coating thickness is more than 6 cm, it will inevitably rise above ground level, which requires the use of curbs. Stone blocks, even with the most insignificant defects, quickly deform and lose their characteristics.

Drawings and design options

Whichever material for the tracks is chosen, it is worth preparing a detailed plan that will allow you to avoid mistakes.

To mark the space of the future track in accordance with the drawing, usually used rope and stakes.

If the pedestrian and terraced path is broken into diamond-shaped, square or triangular blocks, an upper layer of soil is cut through the lines with a spatula or a sharply sharpened knife.Usually, when using tiles, they are placed at the level of a lawn, and on the basis of this considerations, the necessary depth of excavation is determined, taking into account the foundation, of concrete mixes. Leave a gap on the surface for laying the topcoat. Concrete should dry for about two hours (depending on thickness, weather), after which the laying of the stone begins.

When choosing wood, the harvested fragments should be at least 0.1 m in thickness and 0.2 m in diameter. Professionals prefer oak and larch as the most sustainable species.

In depth, the pit should be equal to the total thickness of the tree and sand. Stacked fragments are hammered. Notice deviations from a given depth will help the construction level. The gaps between the wood blocks are filled with sand or gravel.

Beautiful landscape examples

Having dealt with the materials and methods of design, it's time to see what a model garden path might look like.

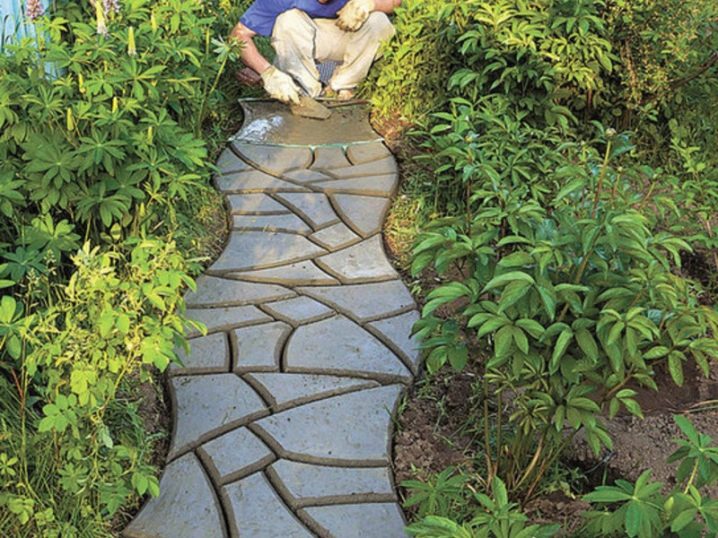

Pavement tiles intricate geometric shape laid in the geogrid, but the workflow is not over.

The chain laid out of the boards can be stylish, especially when alternating almost black and thick red tones,repeating one after another.

But this may look like a series of stones, reaching with a small separation from each other against the background of green lawn grass.

This, of course, is only a small part of the possible options. But it is already clearly visible from them how varied the garden path design can be. Think, try, look for original moves, and everything will work out for you!

To learn how to make a garden path yourself, see the video below.