Dryers: properties and application

Preparing for painting, people choose enamels, lintels, solvents themselves, learn what to apply and how. But there is another very important point that is often missed, not taken into account. We are talking about the use of siccatives, that is, special additives that accelerate the drying of any paintwork material.

What it is?

Sikkativ is one of those components, the introduction of which allows manufacturers to diversify the recipe and adapt it to specific situations, to areas of use. It is added to various paints and varnishes to speed up the process of their drying.

Varieties of compositions

By chemical composition, siccatives are high valence metal salts. Also in this group may include salts of monobasic acids (the so-called soap from the metal). Reagents accelerating drying are applicable to any existing type of paintwork material.

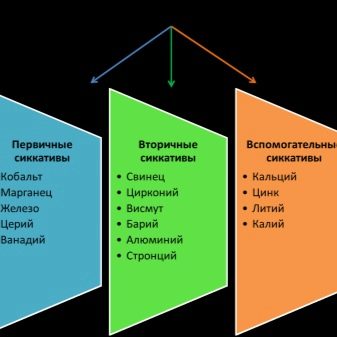

Cobalt and manganese reagents, as well as lead, were first used. A little later, the use of zirconium salts and some other elements began. The vast majority of modern blends are lead-free, because they have a negative effect on human health. Chemists and technologists subdivide the catalysts into first row substances (true) and second row compounds (promoters). A real accelerator is a salt of a metal with varying valency, which, upon contact with the target substance, enters a reduction reaction, then is oxidized to a substance with increased valence.

Helping compounds are salts of metals with unchanged valence. These include zinc, barium, magnesium and calcium compounds. Their role is to increase the effectiveness of conventional mixtures by reacting with carboxyl groups of substances forming a film.Developers take this into account and are increasingly using combined formulations.

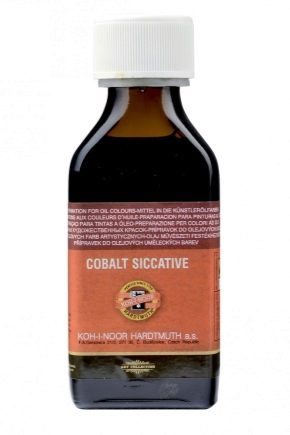

- One-pack dryers On the basis of cobalt, they are recognized as the most effective, but their effect affects only the surface part of the paint film. Therefore, such a metal is suitable only for a very thin layer or on the threshold of hot drying can be used by itself.

- Lead dIt acts in its entirety, it is quite toxic and is capable of forming sulphide stains, as an independent preparation it is rarely used.

- Manganese active and on surfaces and in the thickness. The trivalent metal type is dark brown and this can distort the appearance of the coating. When working it is required not to deviate from the standard formulation - an excess of manganese only weakens the effect, despite the evidence.

Two manufacturing methods - melting and precipitation. In the first case, a thermal effect on oils and resins is practiced, which are then fused with metal compounds. This is a very simple and effective technique. Precipitated substances are obtained by conducting a reaction between metal compounds and salt products of acid processing.Such driers differ in clarified color, contain a stable concentration of intensively acting metals.

- Zinc makes the drying of the surface slower, and the main volume - faster, thus forming a strong film.

- Calcium acts as a promoter in complex mixtures, thanks to him drying becomes easier in the cold.

- Vanadium and cerium act in the volume of paint, but their disadvantage is the yellowness that appears in the applied coating.

- Lead replacements in modern preparations are combinations of zirconium and cobalt.

As for organic acids, there are four main groups of desiccants:

- naphthenate (made from petroleum);

- linoleate (obtained from linseed oil);

- rubber (made from rosin);

- tallish (on the basis of tall oil).

Fatty acid mixtures (such as FA) are formed by dissolving a polyvalent metal salt in a fatty acid or by mixing such solutions with naphthenic acids. The use of such substances is possible both with varnishes, paints of the alkyd type, and in combinations with flax oil.Externally, it is a transparent liquid for light, in which there is from 18 to 25% non-volatile substance. The concentration of manganese ranges from 0.9 to 1.5%, and lead may contain more, at least 4.5%.

Fatty acid siccatives interact with linseed oil, not giving turbidity and sediment. The minimum flash point is 33 degrees of heat. Important: Ready-to-eat siccatives of this group are poisonous and can cause a fire. If it has been 6 months after the release date, you must carefully check the substance, if it has not lost its qualities.

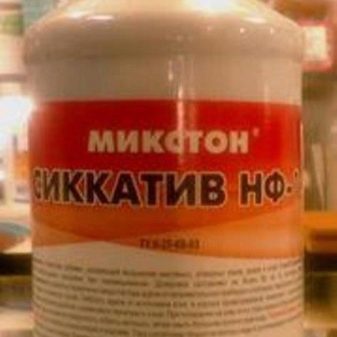

The drug NF1 is a combination of "lead-manganese." It is a liquid substance obtained by the deposition method. Earlier analogues of this mixture are NF-63 and NF-64. It is necessary to add drying accelerator in dyes of oil and alkyd nature, in enamel and varnish materials, drying oils. NF1 is ideally transparent and homogeneous, does not have the slightest sediment or impurity. Acceptable combined use in conjunction with catalysts based on Co. Among them, the best NF-4 and NF-5. When mixed with paint and varnish materials, the chemical is injected in small portions, maintaining a concentration of maximum 5% of the amount of film former.The digital index after the letters NF indicates the chemical composition of the drug. Thus, the number 2 indicates the presence of lead, the number 3 - the presence of manganese, 6 - calcium, 7 - zinc, 8 - iron. Index 7640 shows that the drug is formed by a combination of cobalt rubber with oil and a solution of lead and manganese salts in white spirit. Such a tool can also be used in the restoration of a lost moire enamel pattern.

Important: applying whatever sikkativ, you need to pay attention to the dosage. Excessive introduction of the reagent dramatically lowers the rate of drying of the films and can even change the shade of the coloring composition, especially if it is white initially. Cobalt octanate, dissolved in white spirit, can have an effect of opalescence. The largest proportion of non-volatile substances is 60%, the concentration of metals ranges from 7.5 to 8.5%. There are no copper driers, only pigments are produced on the basis of this metal.

Manufacturers

Among the various brands of siccatives, it is deserved to put the company's products first. Borcherswhose production is very perfect and meets the latest technological requirements. Judging by the reviews, it is necessary to introduce such mixtures in very low concentrations, they are quite economical and practical, and allow you to avoid many problems.

Another leading German manufacturer - concern Synthopol, he also produces high-quality and good-quality products.

Making your own hands

The recipe for the dryers is relatively simple. To obtain a mixture suitable for processing linseed, corresponding to GOST, it is necessary to use fused rubber. Porcelain (in extreme cases, metal) dishes filled 50 g of rosin. It melts at temperatures of 220-250 degrees Celsius. After melting, the substance is stirred and 5 g of quicklime is added to it. By replacing lime with 15 g of lead choke, which is ground with linseed oil to a paste, and then introducing small portions into the rosin, you can get lead rubber. To interfere with both versions of the compositions need to form a homogeneous mass. Drops are periodically removed and placed on a transparent glass, as soon as they themselves become transparent, it is required to stop heating.

You can also prepare manganese oxide, obtained from sodium sulfite and potassium permanganate (more precisely, their solutions). When mixed, a black powdery precipitate is formed. It is filtered and dried in the open air, no heating is needed, it is even harmful.

Scope of application

The use of driers for oil paints has its own subtlety; if an excess of oil derivatives forms in the paint layer, it may re-soften. The reason - the polymerized oil is subject to colloidal coagulation. Combined varnishes, according to some experts, may not include dryers, because the inclusion of cellulose nitrate increases the speed of drying. But in water systems, as with the need to get the most rapidly drying varnish, it is necessary to add desiccant.

Practical experience has shown that significant temperatures eliminate the need for hardening accelerators. Dryers should always use exactly those recommended by paint manufacturers.

Usage tips

The calculation of the amount of desiccant that must be added to the alkyd varnish PF-060 for effective solidification ranges from 2 to 7%. With the introduction of such additives drying time is limited to 24 hours. This result is achieved even with the abandonment of lead-containing preparations in favor of more modern technological solutions, which are often found with mistrust. In most cases, the shelf life of dryers is six months.

Important: for any ready-made mixtures recommendations for the introduction of a desiccant do not apply in principle. Already in production, the necessary amount of all substances was initially introduced there, and if not (low-quality goods), it would still not be possible to assess the problem and fix it at home. With respect to the film former, you can enter from 0.03 to 0.05% cobalt, from 0.022 to 0.04% manganese, from 0.05 to 2% calcium, and from 0.08 to 0.15% zirconium.

Attention! The proportions are given in terms of pure metal, and not on the absolute volume of the mixture, its quantity, of course, is somewhat larger.

In the presence of soot, ultramarine and some other components in the composition of the coloring matter, the surface effect of the desiccant is weakened. You can fight this with the introduction of increased doses of the drug (both immediately and in separate portions, more detailed recommendations can be given only by a qualified technologist).

How to apply desiccant with linseed oil, see the next video.