Drying oil: varieties and uses

Decoration of premises often involves the processing of their paints. This is a familiar and convenient solution. But in order to properly apply the same linseed oil, it is necessary to thoroughly study the features of such a coating and its varieties.

What it is?

The tree returns to the number of leaders in consumer preferences, and plastics and other synthetic materials lose their demand. But it is important to understand that wood needs professional, high-quality processing, and the lintel makes it possible to cover the wooden base with a protective film, while ensuring a high level of sanitary safety. The main part of such compositions is formed by natural components (vegetable oils), and they account for at least 45% of the mass.

Application features

Lepifas was first mastered by artists a few centuries ago. The method of production has changed quite a bit since then, but there are several key types of material that need to be applied differently.

Processing the combined composition is practiced due to its great cheapness (up to a third of the mixture falls on the solvent, mainly white spirit). Drying rate increases dramatically, the reliability of the layer created is very high. Basically, such combinations are used for exterior finish of wooden surfaces, from which the unpleasant smell quickly disappears.

All drying oils, excluding natural formulations, contain substances that are prone to fire and even explosion, so you should handle them as carefully as possible.

When covering the wood, natural wood drying dries for a maximum of 24 hours (at a standard room temperature of 20 degrees). Hemp compositions have the same parameters. Mixtures based on sunflower oil after a day still a little sticky. Combined materials are more stable and are guaranteed to dry for 1 day. For synthetic varieties, this is the minimum period, since their level of evaporation is less.

Often (especially after long-term storage) there is a need to dilute the drying oil. Natural mixtures are preserved in the best condition, as vegetable oils are capable of being in a liquid consistency for a long time. Given the danger of such compounds, to dilute the thickened mixture, you need to thoroughly prepare.

For this you need:

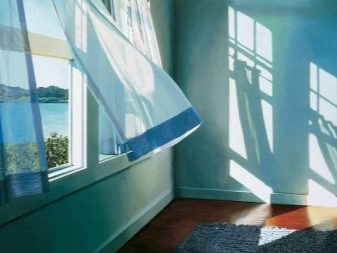

- choose a room with excellent ventilation;

- work only far from open fire and heat sources;

- apply strictly tested formulations recommended by the manufacturer for a particular material.

When working with synthetic materials, as well as with mixtures of unknown chemical composition, you should wear rubber gloves before diluting.

It is important to remember that in case of contact with the skin, certain substances can cause chemical burns.

Most often when diluted with drying oil is used:

- White Spirit;

- castor oil;

- other industrial chemicals.

Typically, the concentration of the added solvent in relation to the weight of the linseed oil is a maximum of 10% (unless otherwise provided by the instructions).

Experienced professionals and builders do not use drying oil, which for more than 12 months remained in a hermetically sealed container.Even with the preservation of the liquid phase, external transparency and the absence of a precipitated sediment, the material is no longer suitable for work and is a great danger.

With confidence in the quality of the protective coatings that precipitated, it is sufficient in most cases to filter the liquid through a metal sieve. Then the fine particles will not be on the surface of the wood, and it will not lose its smoothness. You can often hear statements that the linseed oil should not be diluted at all, because it still will not restore its characteristics. But, at least, the fluidity and viscosity will improve, the penetrating ability will increase, and therefore it will be possible to cover with a linseed oil the area that does not require high quality processing.

Stabilization of wood with linseed oil implies that the processed products must be completely immersed in the liquid.

During operation, the quality is checked in stages, carrying out control weighings at least three times:

- before soaking;

- after the final soak;

- after the end of the polymerization process.

To dry the polymer and make it harden rather, the bars are sometimes put in the oven or boiled in boiling water.Window putty can be made on the basis of a mixture of drying oil and ground chalk (they are taken, respectively, 3 and 8 parts). The readiness of the mass is estimated by how homogeneous it is. It needs to be pulled, and at the same time the resulting tape should not be torn.

Types: how to choose?

Regardless of the abundance of manufacturers, the methods of production are about the same, at least in relation to natural formulations. Vegetable oil is taken, heat treatment is carried out, and at the end of filtration, driers are introduced. GOST 7931 - 76, according to which such material is produced, is considered obsolete, but there are no other regulatory documents.

The composition of drying oil can include various types of desiccant, primarily metals:

- manganese;

- cobalt;

- lead;

- iron;

- strontium or lithium.

When meeting with a chemical formulation, you need to focus on the concentration of reagents. The safest are cobalt-based siccativa experts, whose concentration should be 3-5% (lower figures are useless, and larger ones are dangerous). At higher concentrations, the layer will undergo polymerization extremely quickly, even after drying, because the surface will darken and crack. For this reason, painters traditionally use paints and varnishes without the introduction of dryers.

Drying oil brand K2 is designed strictly for interior decorating, it is darker than the 3rd grade. The presence of such a substance increases the uniformity and uniformity of drying. To apply the material, you will need a brush.

Natural

This linseed oil is the most ecologically pure, there is also a desiccant in it, but the concentration of such an additive is small.

The main technical characteristics (properties) of natural drying oil are as follows:

- sikkativa share - maximum 3.97%;

- drying occurs at temperatures from 20 to 22 degrees;

- final drying requires exactly one day;

- composition density - 0.94 or 0.95 g per 1 cu. m .;

- acidity is strictly normalized;

- phosphorus compounds can not be present more than 0.015%.

Subsequent surface treatment with varnishes or paints is impossible. Wood fully retains its decorative parameters.

Oksol

Drying oxol is obtained with a large dilution of vegetable oils, such a combination of substances must comply with GOST 190-78. In the composition must be present 55% of the natural components, to which are added solvent and desiccant. Oksol, like a combined drying oil, is impractical to use in rooms - solvents emit a strong unpleasant odor, sometimes remaining even after solidification.

The advantage of this mixture is reasonable price. Using the composition can be diluted oil paints, as its own protective properties of the material is not enough in practice. Among the different types of oxoles, it is best to apply linseed oil-based compounds that form a stronger film and dry faster.

Oksol is divided into several types. So, the material, marked with the letter B, can only be used for outdoor work. The composition of the PV is needed when you want to cook putty.

In the first case for the production of the mixture you need flaxseed and hemp oil. Oxol category B can serve to obtain oil or dilution of thickened paint. In the decoration of floors such mixtures can not be used.

Drying oil Oksol brand PV is always made from technical camelina and grape oils. It also contains vegetable oils that cannot be used for food directly or by processing: safflower, soybean, and unrefined corn. In the raw material should not be more than 0.3% of phosphorus compounds, they should be even less, depending on the method of counting.It is allowed to open metal packaging only with tools that do not produce sparks upon impact. It is forbidden to make an open fire where the drying oil is stored and used; all lighting devices must be mounted in an explosion-proof manner.

Drying oil can only be used:

- outdoors;

- in intensively ventilated areas;

- in rooms equipped with supply and exhaust ventilation means.

Alkyd linseed oil

Alkyd varnish varnish at the same time very cheap, extremely durable and mechanically resistant. Such mixtures are needed where abundant precipitations are constantly falling, there are temperature drops and solar radiation. For at least several years, the surface of outdoor wood constructions will remain in excellent condition. But alkyd compounds are allowed only as a means of pretreatment, in an autonomous form, they are not effective enough. It is impractical to apply them indoors, because of the strong unpleasant odor.

Alkyd linseed oil should be applied on wooden surfaces with paint brushes, and they are cleaned in advance and monitor dryness.Approximately 24 hours after the first layer, you need to put the next one, while the temperature is between 16 degrees and more.

Drying oil based on alkyd resins is divided into three main groups:

- pentaphthalic;

- glyphthalic;

- xyphthalic

Basically, such materials are supplied in transparent containers, occasionally in barrels. Approximately 20 hours after impregnation, it is possible to coat the wood with a layer of paint.

Colors of drying oil are determined by the method of iodometric scale, like many other paints. The coloring is affected by the tone of hydroxy carboxylic acids and the type of vegetable oils used. The brightest tones can be obtained by using dehydrated castor oil. Where electric current flows, dark areas are formed, they can also be caused by strong heating and the appearance of significant amounts of sludge.

Regarding the expiration date, current state standards do not prescribe it directly.

The maximum storage time of drying oil is 2 years (only in rooms that are most protected from negative external factors), and for 2 to 3 days you can leave it in the open.Toward the end of the shelf life, the material can be used, if not for protective purposes, then as a means for ignition.

Polymer

Polymeric drying oil is a synthetic product obtained by the method of polymerization of petroleum products and diluted with a solvent. The smell of such a material is very strong and unpleasant, under the influence of ultraviolet radiation, rapid decay occurs. Polymeric drying oils dry quickly, give a strong film with a glossy sheen, but the joinery badly soaked with them. Since the formulation does not include any oils, the pigment sedimentation rate is very high.

Polymeric varnishes should be used when diluting oil paint dark tones intended for minor painting work; necessarily required to intensively ventilate the room.

Combined

Combined varnishes differ little from partially natural, but they include 70% of oils, and about 30% of the mass falls on solvents. To obtain these substances, it is necessary to polymerize drying or semi-drying oil and release it from water. The key area of use is the release of thickened paint, the complete drying takes place within a day. The concentration of non-volatile substances is at least 50%.

The use of combined drying oils sometimes gives the best results.than the use of oxol, especially in indicators such as strength, durability, resistance to water and resistance to weathering. The risk of thickening during long-term storage due to chemical reactions between free fatty acids and mineral pigments must be taken into account.

Synthetic

All synthetic series drying oils are produced by refining oil; GOST has not been developed for their production, there is only a number of technical conditions. The color is usually lighter than that of natural formulations, and the transparency increases. Slate varnishes and ethinol give a strong unpleasant odor and dry for a very long time. Shale material is obtained by oxidation of the same oil in xylene. It is used mainly for dark tinting and diluting the paint to the desired consistency.

It is unacceptable to use synthetic impregnation for floor boards and other household items. Etiolol is lighter than shale material, it is produced using waste material after receiving chloroprene rubber. The created film is very strong, dries rapidly and externally shiny,it effectively resists alkalis and acids. But the level of its resistance to weathering is not large enough.

Compositional

Composite linseed oil is not just lighter than natural or oxol, but sometimes has a reddish tint. The cost of material is always one of the lowest. But it is used only in extremely rare cases, the paint and varnish industry has not used such a substance for a long time.

Consumption

To ensure the minimum consumption of material per 1m2, it is necessary to choose oxol, especially since all combinations of this series dry faster than natural mixture. Linseed oil is consumed by 0.08 - 0.1 kg per 1 sq. Km. m, that is, 1 liter it can be placed on 10 - 12 square meters. m. The consumption of weight for plywood and concrete for each type of drying oil in a particular case is strictly individual. It is necessary to find out the relevant data in the instructions from the manufacturer and in the accompanying materials.

Usage tips

Drying time is reduced when choosing solutions with the addition of polymetallic driers. Natural flax material will dry in 20 hours mixed with lead, and if manganese is introduced, this period will be reduced to 12 hours.When using a combination of both metals, it will be possible to reduce the wait to 8 hours. Even with the same type of desiccant, the actual temperature is important.

When air is heated to more than 25 degrees, the rate of drying of the drying oil with cobalt additives is doubled, and sometimes with manganese ones. But the humidity of 70% dramatically increases the drying time.

In some cases, users are not interested in applying drying oil, but on the contrary, an effective way to get rid of it. From the wooden surfaces such material is removed with gasoline, which rub the desired area. It is necessary to wait 20 minutes, and the oil will collect on the surface. This technique will only help against the surface layer, the absorbed liquid is no longer subject to extraction. White spirit can be considered a replacement for gasoline, the smell of which is somewhat better, and the principle of action is similar.

It is acceptable to use paint thinner, but not acetone, because it will not bring results. It should not be confused with linseed oil and stain, the role of the latter is purely decorative, it does not have protective properties.

Save from the smell in the apartment is very important for a large number of users who make repairs.It is necessary to put furniture in the kitchen or to carry out finishing work, as this unpleasant smell begins to haunt the tenants for several weeks or even months. Therefore, after processing, you need to air the room for at least 72 hours, preferably even at night. The room itself must be tightly closed to remove unwanted "flavor".

Then the newspapers are burned. Better not even their burning in fire, but slow smoldering, because it produces more smoke. The collected smoke can not be ventilated for at least 30 minutes. It is not necessary to act in this way if the treatment has been carried out with varnish.

Without fire, you can get rid of the smell of linseed oil with the help of water: several containers with it are put in the room and changed every 2-3 hours, the release from the unpleasant smell will occur on the second or third day. Putting salt near the surfaces finished with linseed oil, it is changed daily, freshness comes on the third or fifth day.

Many are interested in the question of whether it is possible to apply varnish on top of drying oil or not. Both types of materials form a film. When drying applied to fresh varnish varnish air bubbles are formed.NC-132 dyes and some other paints are compatible with this impregnation. It is unacceptable to apply the coating at subzero temperature; moreover, oxol is applied at temperatures of at least +10 degrees.

Tile glue (waterproof) is made of 0.1 kg of wood glue and 35 g of drying oil. Drying oil is added to the melted glue and mixed thoroughly. With subsequent use, the finished mixture is necessarily heated, it is useful not only for the tile, but also for connecting wooden surfaces.

How to do it yourself?

In the absence of factory production, quite high-quality drying oil is often made at home from sunflower oil. To obtain a product based on flaxseed oil, it will be necessary to slowly warm it up, ensuring the evaporation of water, but not heating it above 160 degrees. Cooking time is 4 hours, it is undesirable to cook at the same time a large amount of oil. By filling the vessel in half, you can provide increased protection against fire and provide significant performance.

When the foam appears, you can enter the siccative in small portions - only 0.03 - 0.04 kg per 1 liter of oil. The time of the subsequent cooking at 200 degrees reaches 180 minutes.The readiness of the solution is assessed according to the full transparency of the drop of the mixture placed on a clean thin glass. It is necessary to cool the drying oil slowly at room temperature. Siccativa is also sometimes made by hand: 20 parts of rosin are combined with 1 part of manganese peroxide, and the rosin is first heated to 150 degrees.

On how to properly apply the linseed oil, see the following video.