Welded roof: what it consists of and how it fits?

Roof - an important element of any modern structure. It protects the house from external damage. There are several types of such structures, differing in shape and physical characteristics.

Particular attention should be paid to flat roofs, which are covered with special roll materials. This coating provides a durable design that can withstand maximum wind and temperature loads.

What it is?

Arrangement of flat roofs does not allow to use metallic materials for their protection, as they do not drain water well and quickly collapse. This is due to the fact that the design has a minimum slope.An alternative to such products is a fused roof, which is a rolled material that is fixed on the base under the influence of temperature.

The main connecting element here is bitumen or its derivatives. Produce products in the form of rolls of various structures and widths. Technically, such products act as an upper protective layer, under which several additional layers can be placed.

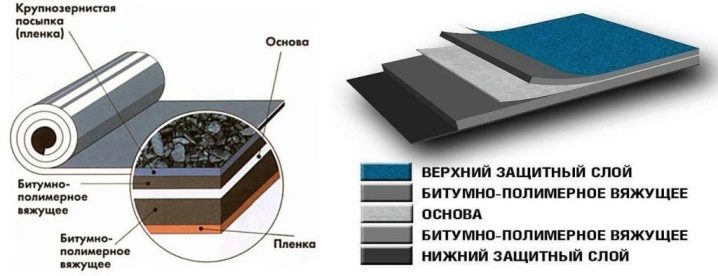

The structure of the upper protective roll implies the presence of several basic layers (bottom to top).

- Melted materials. Bottom have a special raw material, which can be melted when exposed to high temperatures. This contributes to the connection of the roll with the prepared substrate. Make this layer of various polymeric substances.

- Bituminous substrate. Its main purpose is to provide waterproofing.

- The reinforcing (base) layer. It is made of special reinforcing substances that are able to withstand high temperatures. With it, the roll retains its structure and can not be cracked or scattered.

- Bituminous substrate. Used as an additional waterproofing layer.

- Protective layer. It consists of various solid granules that are deposited on a preliminary bitumen substrate.

It should be noted that all these components can be made of different materials. Such a combination allows you to impart certain technical parameters to the product, which will easily withstand the external environment.

Features and device

Overlaying roofs can only be used for structures that have a relatively small carcass slope. Technically, laying them on pitched modifications is possible, but it requires high financial and physical costs, which is unprofitable. Therefore, such structures are often laid on the concrete flat roofs of residential houses or technical buildings.

The popularity of such a roof is due to several of its advantages.

- Waterproofing. If the installation is done correctly, a strong bond is formed between the joints of the rolls, excluding the ingress of water.

- Thermal insulation. The deposited materials retain heat very well, which does not allow the interior to cool quickly.In addition to this, the products also suppress noise well, which makes it indispensable for houses located in large cities.

- Durability. The service life of such roofs can exceed 20 years. At the same time, the upper layer during this period does not lose its original properties.

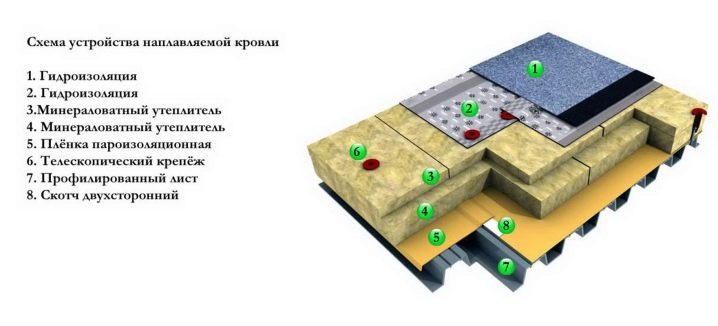

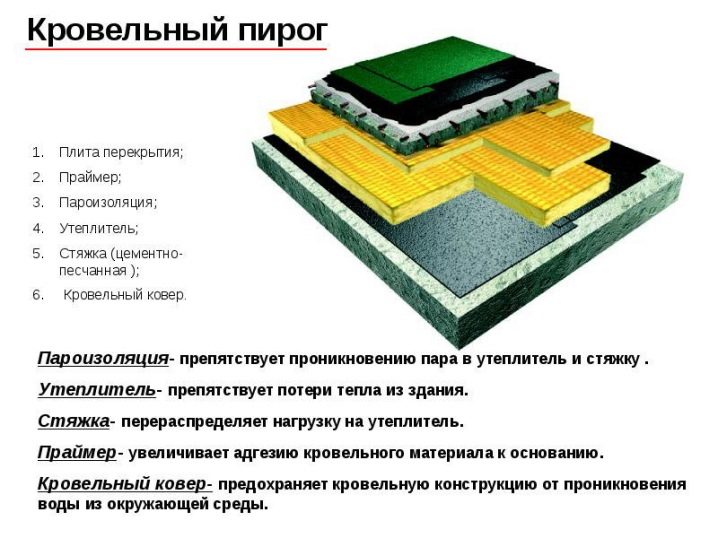

The roofing “cake” of such products assumes the presence of several optional layers.

- Vapor barrier. It is located directly on the concrete floor itself. It limits the movement of vapors of fluids between the layers of the structure.

- Insulation. This layer is not mandatory, but insulated roofs are practiced today almost everywhere. In most cases, this system may consist of several substances. Extrusive materials are used as a substrate (expanded polystyrene plates, etc.). On top of them are often laid expanded clay. But sometimes the latter type of raw material can simply be replaced by a thicker layer of piece insulation. It is from such products that a small slope is formed that allows organizing the flow of water.

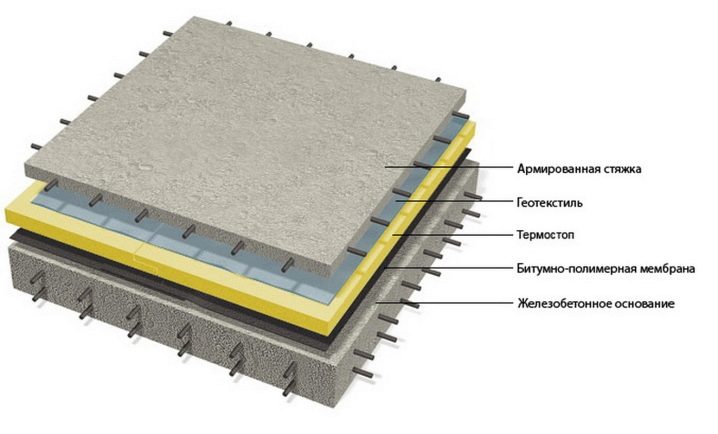

- Reinforced screed. The thickness of this layer may vary depending on what type of roof is being covered.

- Bituminous primer. The material is used as a substrate for the top covering materials.

- Rolled waterproofing. This substance is a deposited material. It is placed on the base in several layers. It is important here that the lower and upper joints do not overlap.

Types and materials

Soft built-up roof involves fixing the structure to the base by heating the substrate, which is set to the roof frame. To classify the roofing of this type can be according to various criteria.

The basis for a rolled roof can be made of various materials.

- Roofing paperboard. Relatively inexpensive substance that can withstand heavy loads. But to operate the rolls on such a basis is possible only in the temperature range from -20 to +40 degrees.

- Asbestos paper. It is not used as the main coating. But this material is a good lining for the main protective layers.

- Fiberglass fabric These rolled materials are highly durable. But it is recommended to use them only for static roofs. If the structure begins to move with time, this may lead to the tearing off of the upper layer.

- Fiberglass It is also desirable to use the material on stable structures, as it is characterized by medium strength.

- Polyester. This fabric has strong and elastic characteristics. Some varieties of this product can stretch during operation up to 30% of their original parameters.

Another important component of overlaying roofs is a binder.

Today, in the manufacture of such products use several materials.

- Oxidized bitumen. Rolls of such substances are unable to resist external loads qualitatively. Therefore, they are very often used as an additional waterproofing substrate.

- Polymerized bitumen. Impregnation of this kind allows to operate the roof already at temperatures from -15 to -25 degrees. The strength of the web material already depends on the production technology and the additives used.

- Styrobutane styrene. Excellent bonding material, which gives the coating high strength and resistance to temperature extremes. Experts recommend using it in places with a harsh climate.Such products are also called artificial rubbers, which in composition and physical properties resemble natural counterparts.

Tools and equipment

The deposition of overlayed roofs is not very complex. But it should be borne in mind that the quality of the surface depends on the observance of many nuances.

For the implementation of the installation of roll-up rolls need to stock up auxiliary tools.

- Gas-burner. It must be complemented by a long hose, which will simplify manipulation. For reliability, the hose must be supplemented with a special gearbox. The burner is used to heat the lower binder layer of the bitumen roll. Therefore, the device should be light and practical.

- Gas cylinder. The capacity is often insignificant, as it will need to be periodically transferred. If necessary, it is better to refill the cylinder with gas or use other elements. The gas hose connection must be carried out in accordance with the instructions and compliance with all safety regulations.

- Roofing knife and fire extinguisher. The first element is used for trimming rolls when laying them on complexsurface. Sometimes experts also recommend taking an ax with you.

- Metal brushes for cleaning coatings.

- Rollers and special bitumen primer.

The number and type of tools may vary depending on the technology of applying flexible roofs.

Foundation preparation

Welded roof is a kind of cake. It is laid on a previously prepared basis. The quality of the frame is very important for the implementation of such work. Therefore, it is important not only to properly prepare the base, but also to select its type.

Demand

Roof base is an important element that you need to pay attention to when choosing a material to cover such surfaces.

It is possible to use overlaid substances only with structures that meet certain requirements.

- Stiffness and evenness of the surface. It is impossible to spread the rolls on the crate, as the material will sag, forming a loose structure.

- High resistance to fire. Bituminous roofing substances burn very well. Therefore, the base itself should act as a kind of barrier.It is not allowed to install rolls on any wooden structures. Sometimes some specialists use OSB as a substrate. But it should be understood that no matter how they are soaked with protective agents, it is still a tree.

Under such requirements fits several types of bases and materials.

- Hard mineral wool. It is recommended to use plates, the tensile strength of which is not less than 0.06 MPa.

- Concrete floors. The best option for the deposition of deposited substances. The material withstands high temperatures and is also resistant to burning.

- Extruded polystyrene foam.

- Asphalt or expanded clay base.

But all the considered types of materials are often laid on concrete floors as auxiliary elements.

Training

Particular attention should be paid to the preparation of concrete frames, as they are the main places where the built-up roofs are used.

The preparation of these surfaces involves the implementation of sequential actions.

- Cleaning the base. Initially, all debris and dust should be removed from the floor. This will allow you to get maximum adhesion of the roll with the frame.

- Remove grease and rust stains. In the first case, it is desirable to completely remove the cement mortar in order to get rid of ingrained materials. If at the same time there was a big deepening, it is desirable to level it with cement mortar. Rust is cleaned with special mixtures or abrasive materials.

- If the surface has significant differences in height, then you need to additionally level it with a screed. This option is used if the drop is more than 5 mm per 1 square meter. The thickness of the screed should not be less than 3 cm.

- Vertical structural elements must be plastered and sheathed with DSP plates. In the presence of cracks and other similar damage, they should be sealed with sealants or other materials.

- Padding. As primers, special bitumen primers are used.

Mounting technology

Arrangement of built-up roofing is a relatively simple operation. Installation of such coatings is carried out in several ways, which depend on the type of roof. Regardless, experts recommend placing roll materials in at least two layers to ensure the desired level of waterproofing.

Flat roof

The technology of mounting overlaid roofs on flat roofs consists of several successive operations.

- The arrangement of the substrate. This layer is used if the insulation of the roof is carried out. Initially, waterproofing is laid over the ceiling. Then on it form a roofing cake of heat insulation and concrete screed. If you carry out such operations, you need to create a surface with a minimum bias in one direction.

- Fastening rolls. First install special bumpers at the junction of horizontal and vertical bases. Often these products have the form of corners with a bevel of 45 degrees. When the surface is ready, proceed to gluing the first layer. To do this, the material is heated and gradually rolled, pressing against the concrete base. If the roof area is significant, then you need to take into account the consumption of propane in order to stock up on the necessary amount of it. When laying sheets, special attention should be paid to the eaves nodes and other vertical elements. When they cover it is necessary to exclude the possibility of water ingress under them. If pieces are used, then they should be placed on top of the lower layers.

It is recommended to carry out laying of the built-up roofs in the summer. But with the observance of technology and proper preparation of the base, this problem can be solved in the winter.

Skat

Overlay materials are rarely used on pitched roofs. But technically, the use of these systems is possible only for structures whose slope does not exceed 50 degrees.

The algorithm for mounting overlaid roofs on pitched roofs consists of certain sequential actions.

- First of all, OSB plates are attached to the batten, which should completely cover the entire surface. Insulation and waterproofing is located directly under them. Often the roofing cake is formed between the roof beams.

- After this, the plates are covered with a special bitumen primer. This will increase the adhesion of the joined materials. For better impregnation in the composition, you can add diesel or gasoline.

- Finishing laying gluing rolls. To this end, the lower layer of the roofing material is heated with a burner and subsequently glued to the slabs. Carry it out consistently, expelling air from under the roll.Please note that installation of several layers is possible even in the transverse direction. It is important here that the upper roll rolls down from above.

Cool way

Fixing roof sheets today can be carried out by the cold method. This approach involves the use of special solvents.

Fastening technology can be described by a series of sequential actions.

- Initially, a special solvent is applied on the prepared concrete base and on the bottom surface of the roll. This action is carried out simultaneously using a special machine. She also performs rolling sheets along the roof.

- After 10-15 minutes the sheets are aligned and pressed against the base. During this time, the solution will take effect, and the bottom layer of the roll will become liquid.

Tips and tricks

Arrangement of built-up roofing is a simple process.

In its implementation, it is important to adhere to fairly simple recommendations.

- Old bases should be carefully prepared for such work. If rolls have already been applied to them, then you need to first disassemble them, then clean and repair the concrete surface.

- Be sure to consider the weight of people and structures that will be on the floor. Some types of roofing are fragile and require additional reinforcement.

- All rolls should preferably be spread in one direction. In addition, each new sheet is placed on top of another with an offset of 15-30 cm.

- When the slope of the roof is less than 15 degrees, the elements can be positioned along the longest side. This greatly simplifies operations and also minimizes waste. If this figure is above 15 degrees, then the sheets need to be laid only along the slope.

- When heating bitumen, be sure to ensure that the entire surface warms evenly. It is undesirable to overheat the material, as this affects its strength.

Manufacturers

Modern materials of this group are very popular, as they allow to obtain a durable coating in a relatively short period of time. But the quality of such products depends a lot on the manufacturer. Today in the market can distinguish products of several companies.

- "TechnoNIKOL". The products of this manufacturer are of high quality and durability.The company produces materials for both conventional and "breathing" roofs. One of the most famous built-up roofs. Here you can find both premium products and budget options with a service life of up to five years. Among the modifications of roll products can be identified options such as "Technoelast", "Vestoplast" and many others.

- "Poliruf". The manufacturer produces rolls of the same name, which can be operated in the temperature range from -25 to +90 degrees. The service life of this material can reach 25 years.

- Filikrovlya. One of the most popular manufacturers of roll materials. Technically, the products are similar in composition to products from the previous manufacturer. The service life is 25 years.

The built-up roof is an important element that allows you to get reliable protection with minimal cost and physical effects.

How to lay the built-up roof with your own hands, see the next video.