Brick: types, properties, applications

Brick is perhaps the most recognizable building material in the whole world, since its technology has been known to many civilizations since ancient times. At the same time, different nations made it from scrap materials and with their local characteristics, and today, in the century of developed technologies, its different varieties have become even more different from each other. Over the millennia of use, this unique building material has not lost its value and has not yet retreated in front of more modern alternatives. At least, therefore, it is worth considering what it is today.

Production technology

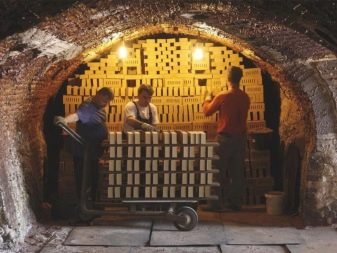

Most of the “classic” brick types (for example, adobe, ceramic, or silicate) are made from what is literally under your feet. The first two raw materials are clay, in the case of saman, it is also diluted with viscous grass or manure, in the third case lime and sand are the base material. Initially, each person was engaged in the preparation of raw materials as needed, the same way the further production of bricks took place - many enterprising owners today prefer to make saman for buildings on their own site with their own hands. In ancient times, there was no special technology; therefore, they were manually engaged in shaping (a little later, also manually, but with the help of specially made forms), usually dried in the sun, and burned in special furnaces, also self-made.

About 160 years ago, a revolution occurred in the brick industry, when mass production technologies appeared. - for example, ring kiln and belt press, and a few decades later - special clay processing machines and dryers. Due to this, the appearance of cities has changed beyond recognition - instead of wooden huts, even relatively poor people began to build brick houses, because the processremaining unchanged, they began to almost completely perform the machines, working at a much higher speed. Thanks to the organization of production in conditions of specially equipped premises, brick factories could work all year round, without being tied to the summer, as was done before, in order to dry the bricks.

Today, the variety of bricks has become much more, because the traditional “recipes” have been improved with numerous new ingredients that allow to improve the basic properties - to increase strength and durability, to reduce thermal conductivity, weight and cost, to improve the design. In each case, the production technology may be slightly different, but in general the steps are the same - raw material harvesting, molding and hardening through drying, firing or other procedures.

Types and their characteristics

Today one can count many varieties of this building material, differing not only in composition, but also in properties. Such competition persists not just because each has its own advantages and disadvantages, but also because of the focus of each type on a specific field of application.It is for this reason that before starting construction and choosing the type of bricks, it is worthwhile to figure out why you need at least the most popular types.

In the post-Soviet space, silica brick is the most popular - the very characteristic white shade. It is made on the basis of lime and sand, of which there are many in any region, because such material is inexpensive - it is easy to get raw materials for it, and the finished product does not need to be carried far. Production also does not require outstanding technology - the whole trick is usually just a very thorough pressing. Unfortunately, a mass product rarely has impressive consumer characteristics, so the silicate brick does not impress with its ability to retain heat, and even is afraid of moisture. Such a material weighs a lot, but it does not differ in particular strength, which affects its sphere of application - load-bearing walls and internal partitions are laid out of it, but not foundations, fireplaces or stoves.

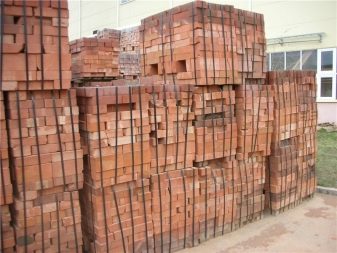

Burnt ceramic bricks are also well recognized for their characteristic red hue. By the way, the color in this case is an indicator of quality, because for too light they regretted the fire, and too dark, burnt - on the contrary, they were kept in the furnace.The firing temperature of high-quality clay, which is the main raw material for this building material, must be equal to a thousand degrees, then they will have all the best qualities - the highest strength and resistance to destruction, so that red brick can be used almost everywhere, including the same foundations and pipes. The only indicator by which this type is worse than silicate is the thermal conductivity, which is lower in the latter.

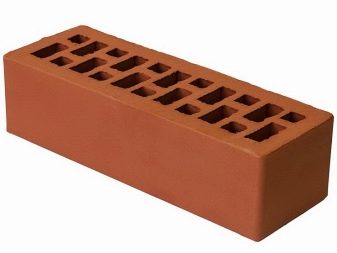

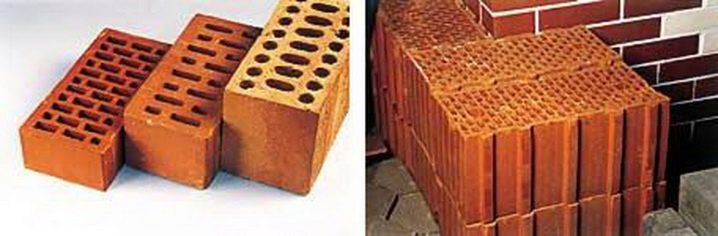

Both of the above described species, like some others, are corpulent and hollow. The first is a solid piece of material without any voids, whereas in the second case, characteristic through holes are usually noticeable, forming the same pattern on each specimen. The production of hollow bricks is always spent less raw materials, because they are lighter and quite cheap, their other advantage is the lower thermal conductivity caused by those same voids. However, this material is more fragile than reliable solid bricks, therefore it cannot be used for the construction of load-bearing walls. The latter, in turn, are often built from full-bodied building materials, but then without additional insulation can not do.

Double bricks, also known as ceramic stones, are visually distinguished by a much larger size, for which they received their name. Contrary to expectations, the elements of such masonry are not always heavier than usual, since they are always characterized by high porosity, which has a favorable effect on the price. The abundance of pores helps to reduce thermal conductivity, because the scope of application is obvious - external walls. The advantage of this material is also the fact that it significantly saves the solution, because the seams in such a wall are much smaller.

Hyperpressed concrete brick is made from concrete, but it is not poured into molds at the construction site, as is usually the case, but arrives there in the form of ready-made blocks of the same size and shape. Contrary to popular belief, such blocks are not necessarily gray - modern manufacturers allow you to choose a shade at the request of the consumer. Concrete bricks are often called artificial stone, and its universal characteristics allow it to be used for the construction of any part of a building or its entirety.

Rubble bricks are often confused with rubble stones, but they are fundamentally different things. A brick of this type, also known as building, ordinary or masonry, is more properly called zabutovochny, because its main field of application is the construction of zabutka, that is, the middle part of the wall that is not visible either outside the house or inside it. In fact, this category simply does not include the best examples of the usual red brick of baked clay - either somewhat burned out, with a characteristic blackening (but not completely burnt), or simply unsuccessful in terms of shape. In this regard, it represents the exact opposite of a facing brick, for which an attractive appearance is fundamental, although this does not mean that you cannot build solid walls out of it.

Restoration brick also does not imply any particular material or variety of bricks. Such a building material is made to order for the restoration of old buildings, its task is to imitate the original material with maximum accuracy. Naturally, in the case of each individual building, it can have a special look.

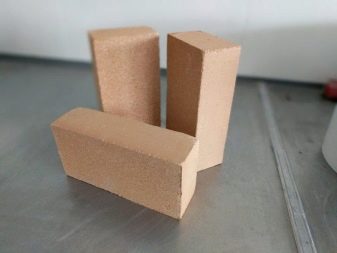

Acid-resistant brick is made of clay with numerous additives like dunite, chamotte powder and sand.Each copy is burned at a temperature of more than 1300 degrees, so it turns out an alloy of all of the above. A characteristic feature of such a building material is its chemical neutrality - it will not take even a strong acid, as well as the ability to withstand extreme temperatures. The scope of application of such a brick is rather narrow - structures are built from it directly adjacent to pipes and other utilities of the chemical industry enterprises.

Diatomite brick is made on the basis of diatomite - a special mineral formed from the fossilized remains of prehistoric diatom algae. It also undergoes firing at a temperature of about a thousand degrees, and in terms of its operational characteristics it is very similar to the above-described acid-resistant building material, although its main advantage is fire resistance. It is noteworthy that under the action of high temperatures, the laying of such a material not only does not collapse, but does not lose its basic properties, including low thermal conductivity and high sound insulation. It is used both for the construction of residential buildings, and in the process of building furnaces of industrial enterprises.

A vibro-pressed brick may contain particles of natural stone (marble, dolomite), calcareous rocks and shell rock, while the binding material for all this heterogeneous mass is ordinary portland cement. The production technology makes it possible to produce such a building material with a surface that fully corresponds to the wishes of the customer - at least ideally even, even aesthetically torn. Color can also be changed at its own discretion, because this type of bricks is usually used for cladding the outer walls of houses.

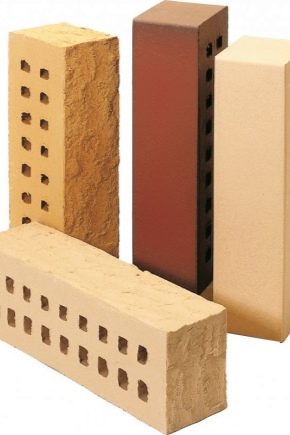

Colors

A few decades ago, when only “traditional” types of brick were in widespread use, the shade of building material spoke of the raw materials from which it was made. So, the white blocks indicated the silicate origin of the building material, and the red ones - on the clay one. In the latter case, the shade could also tell about the quality of production, because too light meant an insufficiently high firing temperature, and too dark, especially with obvious blackness, indicated an excessively strong effect of elevated temperature. Colored brick was completely absent altogether, not allowing to diversify the design of buildings.

In recent decades, the diversity of the composition of building materials began to pay increasing attention. Many manufacturers began to move away from the traditional recipe, adding more and more new ingredients. Many of them were added solely for the sake of obtaining some new properties, for example, increased resistance to extreme temperatures, however, due to their own color, which differs from the main range, they could introduce a certain variety of shades.

Over time, the manufacturers came to the conclusion that the client has the full right to independently choose the appearance of the product, because varieties of blocks began to appear that differ from their fellows only in color. At first, of course, the gamma was close to the already existing one - the first appeared shades such as brown and terracotta, ivory and chocolate. Somewhat later, it became possible to choose building materials of absolutely any color, which partially eliminated the need for additional facing materials.

In terms of cost, bricks of different colors usually do not differ much among themselves (unless the additive that changes shade does not have specific practical functions),However, building materials of unusual colors are produced in a much smaller amount than the usual ones, otherwise the first ones can simply not be sold. Often, bricks of a certain shade need to be specially ordered from the manufacturer.

Sizes and shapes

In antiquity, the exact shape and size of each brick was not always followed, but today, in an age of universal standardization, there are generally accepted size standards that allow not only to lay out a perfectly flat masonry, but also accurately calculate the amount of building material needed in advance. If a packing brick, used exclusively for laying hidden surfaces, may still have a slightly irregular shape (and even then with deviations no more than a few millimeters), then for a facing variety, compliance with all parameters with the highest accuracy is of utmost importance.

As a rule, each side of ordinary blocks on top looks like a rectangle, that is, the length, height and width of a brick are different from each other. According to this criterion, in our country there are three main groups of such building materials:

- single or simple brick - 25 to 12 by 6.5 cm;

- one-and-a-half, or thickened - 25 by 12 by 8.8 cm;

- the double is 25 by 12 by 13.8 cm.

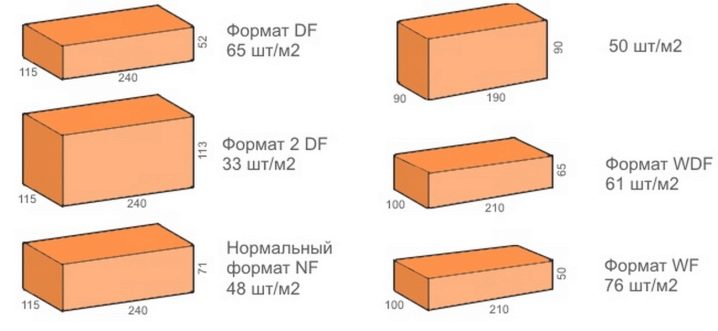

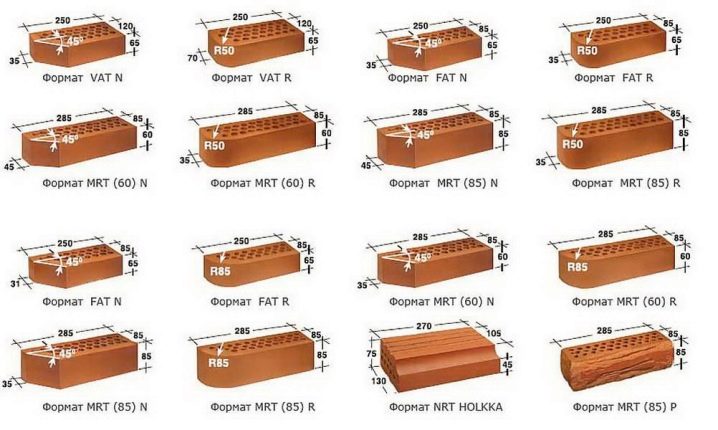

The standards described above relate primarily to domestically produced building materials, while in Europe several different concepts and sizes are adopted. In this case, by the way, the allowable volumes are twice as large:

- DF - 24 by 11.5 by 5.2 cm;

- 2 DF - 24 by 11.5 by 11.3 cm;

- NF - 24 by 11.5 by 7.1 cm;

- RF - 24 by 11.5 by 6.1 cm;

- WDF - 21 by 10 by 6.5 cm;

- WF - 21 by 10 by 5 cm.

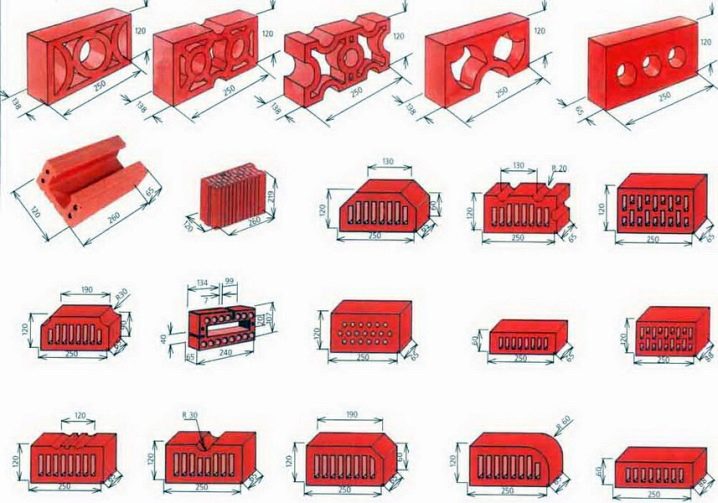

It is assumed that for all the “ordinary” bricks described above, each angle is 90 degrees, thanks to which the correct rectangle is obtained everywhere. However, consumer demand, again, forced manufacturers to think about producing curly blocks that are significantly different in their appearance. Here, fantasy has almost no limits - for example, a corner brick can have one beveled side so that the house does not have one right angle, and instead there are two angles of 45 degrees with a small distance. An alternative solution may be a completely rounded block whose angle simply does not exist. What to say about the blocks, some of which protrude outwards, beyond the limits of the main masonry, imitating the old building of poorly hewn stone.

As in the case of different colors, the non-standard brick shape can be attributed to facing, and if its ordinary brother is needed in the construction of virtually any brick building, then none of the facing options can boast such massive demand - it all depends on the tastes of the customer. For this reason, blocks of unusual shape often also have to be ordered specially, although the most popular varieties in large supermarkets must be in stock.

Spheres of application

Although different bricks are designed for completely different ways of use, it is usually silly to choose one of them for building a full-fledged brick house - this design is quite complex and involves different operating conditions in its individual parts. For this reason, all blocks purchased for construction should be divided into categories and the percentage for each should be calculated correctly.

For the walls of the house, in almost any case, an ordinary one, a building brick, will be used. By such is usually meant a normal, silicate or clay building material, for which there are no special requirements for appearance - it can even have visually noticeable deviations in terms of shape or size.Such drawbacks are not striking, since they are further hidden behind the interior and exterior trim. Since the production does not imply complex technologies (even the size requirements are not adhered to perfectly), such building materials cost the least.

Facing brick is relevant in the event that the customer wants to do without exterior finish and get a beautiful house itself of brick. The procedure for the manufacture of such a product is somewhat more complicated, because at least it must strictly comply with the standard sizes and have the correct shape, and the latter often also involves some figure. The complication of the production process predictably affects the cost, because facing blocks are almost always used only for exterior decoration, hiding behind a less presentable material. For the lining of the building as a whole, they use a textured version, in which all the elements are the same, but for the finishing of windows and other complex architectural forms a shaped brick is used, each copy of which can be purposefully unique.At the same time bricks of both types are used not only for the construction of houses, but also, with sufficient funding, for the construction of beautiful fences. Such building materials are usually made colored.

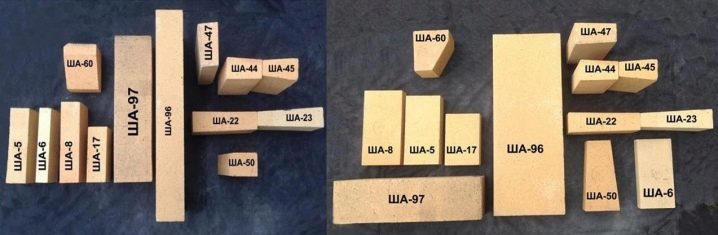

The so-called fireclay bricks were previously called simply stoves, which in many respects reveals its main purpose. Under the common name, several types of bricks are made at once, made of different raw materials and differing in their characteristics, but any one of them theoretically would be suitable for the construction of an ordinary residential building. Any chamotte block differs from the usual one with increased heat resistance - it not only does not collapse under the influence of high temperatures, but also does not lose any of its advantages even with repeatedly repeated heating and cooling cycles. Such a building material can be used for the construction of the whole house as a whole, but usually it costs much more than a simple ordinary brick, because of the fireclay varieties more often lay out only stoves, chimneys and other sections of the wall that will be regularly exposed to strong heating.Most types of fireclay bricks are designed primarily for industrial needs, for example, for the needs of metallurgy or the chemical industry.

For greater durability of the building, you can also use clinker bricks in the construction process. This type is in many ways similar to a simple ceramic red block, but the production process is much more diligent - and the raw materials are chosen more carefully, preferring refractory clay grades, and the firing temperature is higher, so that the mass is sintered into the stone. Raw materials devoid of any impurities, provides the final material with the highest strength and durability, as well as water-repellent and frost-resistant characteristics. Such a brick of selected clay is, of course, significantly more expensive than most others, because it is used sparingly - most often it can be found as a lining of socles or the main material for "eternal" garden paths. Since such a material is not only distinguished by excellent operational qualities, but also is visible, it is almost always decorated with an unusual texture or bright hues, which still slightly increases the already considerable cost.

Tips for choosing

Although the brick seems to be extremely simple, and most importantly - mostly the same, the durability of the building depends on its adequate choice. Even a sophisticated bricklayer will not build a building for ages because of bad construction materials, so you need to wisely choose a brick. We have already talked about how to determine the variety, mentioned also the meaning of the voids in the body of the block - now it is time to reveal some secrets.

Take at least the same dimensions - only at first glance they are a matter of taste. In fact, the larger each individual block, the smaller the seams in the wall, and it is the latter that are rightly considered the weakest point of the masonry both in terms of strength and in terms of thermal insulation. According to this logic, a double brick should be in high demand, but it has its drawback - its large dimensions may require splitting individual blocks too often and even provoke the inability to accurately recreate the contour and planned dimensions. In the end, the double version is simply harder, because the delivery and installation of each individual copy of the force is spent much more.

A good indicator of the strength of a building material is its mark, but not everyone understands that the typical designation indicated in the technical passport has a specific decoding. M100 brand blocks are capable of withstanding up to 100 kg of load per square centimeter of their surface, M150, respectively, 150 kg per area. In general, brands vary from M75 to M300, and, of course, the higher the brand, the more reliable the structure, but along with the durability, the price rises, because the most expensive building material is not worth choosing. Experienced builders indicate that M100 is also suitable for building on the plot, and the same M150 is more designed for multi-storey buildings, but sometimes it is worth making more serious calculations for the weight of the structure to determine the optimal grade with high accuracy.

The brick frost resistance index is somewhat similar, but the figure, contrary to popular belief, here means not the minimum possible temperature, but the number of defrosting and freezing cycles. Every winter is frosty in our area, therefore this indicator should be high - at the level of at least Mrr 50, and even better at Mrr 100.At first glance, this may seem illogical, but in the Far North, high frost resistance rates are not even so fundamental - there are no periodic thaws for winter, because the cycles are usually somewhat less than in those regions where winters are not so severe.

Even in quality products there is a periodic marriage, which greatly affects the properties of building materials. The fact that a burnt or not burnt brick has much weaker performance has already been mentioned, but this can be determined not only by the outer color, but even by the gradation of hue in each individual copy - the “filling” should always look more bright and rich than outer layers. Any external damage also suggests that such blocks should not be taken - if they had time to be damaged during relatively short storage, it is difficult to say what will happen to them during the operation of the building.

If there are blotches in the form of white dots on the cleaved brick, it means that quicklime was present in the original raw material. For building materials, especially facing grades, this is very bad, because in contact with water, the lime will be extinguished, and a spall will remain in its place - a small funnel.At least it looks ugly, and in especially neglected cases such phenomena can disrupt the integral structure of a brick and significantly reduce its strength. For this reason, builders are often advised to choose a proven manufacturer with a good reputation - he will not risk his good name, neglecting possible lime intersperses in his products.

In a way similar to the above described and the situation with efflorescence, when there are too many soluble salts in the composition of the brick, which are not really there. With abundant contact with moisture, such “additives” appear on the surface in the form of characteristic white spots, which usually does not have a bad effect on the performance properties of a brick, but it strongly spoils its appearance. Accordingly, a similar problem is critical for facing blocks, but, on the other hand, there are special washes that will help resolve the issue even if an error has been made in the purchase of building materials.

For many consumers, a peculiar indicator of product quality is also its price relative to competitors. On the one hand, such logic often turns out to be fair, on the other - it is also necessary to understand how the price is formed. For example, European bricks are much more expensive than the average, and Belarusian bricks, on the contrary, differ in relatively low cost, although it’s not a fact that the difference in quality is so great. Elementary logistics is of great importance - the products of nearby factories are always on average slightly cheaper than imported ones. Building materials may also go up in price greatly due to the mass of intermediaries - often a brick is twice as cheap from a manufacturer as a foreign seller on the market.

Finally, a few more simple tips:

- construction and facing bricks must be of the same grade, otherwise there will be a discrepancy in the strength plan inside the wall;

- documents like a certificate of quality or a passport for a product may contain a lot of useful information and are often the only source of knowledge about something that cannot be determined;

- before placing your order, once again specify whether you have ordered the correct grade of building material, otherwise the purchased bricks may be inappropriate for the planned tasks;

- allegedly the same brick from different batches may differ slightly in color and even some other characteristics, therefore for the integrity of the design it is desirable to use products strictly from the same batch;

- Experts note that the seasonal increase in brick prices is usually observed in the summer, so you can save money by purchasing building materials in the spring, because by the winter brick reserves are gradually depleted, so it starts to increase again until the manufacturers intensify production for the new season.

Beautiful examples

Silicate bricks are not taken seriously by many builders - they value the burned red block, which is notable for its increased strength and resistance to various influences, much higher. At the same time, this material is quite suitable for relatively small buildings on a private plot of land - this is once again confirmed by the millions of houses from this building material scattered throughout the country. In this case, a certain variation of shades is also possible, and the fact that the silicate brick usually has a very smooth and even surface is also very important for the external attractiveness of the building.

The situation is even better with red ceramic bricks - it is both stronger and more durable, besides, manufacturers produce it in dozens of shades, which allows combining different shades of building material within one wall to highlight accents. The second example shows that color harmony can be achieved even with a roof - the red tile against the background of baked clay looks very worthy. The holistic artistic image also complements the garden path in the same color.

If, on one example, you want to see several completely different types of blocks involved at once, then you should not even look so much at home as at the fences. It is such small architectural forms that usually provide for various delights, because only a sufficiently wealthy owner can afford such a solution, and the impenetrability of the fence for outsiders, and the external gloss of such a wall, are probably fundamental to him. In the photo, put in the example, you can see that the brick can be of different colors and shades, can have a certain texture, as if protruding beyond the seams, and can also turn the generally accepted idea that the brick should be strictly rectangular and lie only in the horizontal plane.For a pronounced aesthetic effect, the builders also used blocks of different sizes, thanks to which the columns are of unequal thickness and somewhat resemble refined ancient columns.

How to choose a brick for building a house, see the following video.