Slit brick: types and technical characteristics

The success of subsequent work depends on the choice of building materials. An increasingly popular solution is a double slit brick, which has excellent technical characteristics. But it is important to find the appropriate type of material, as well as to understand the specifics of the masonry blocks.

Special features

The advantages of a brick block are:

high density;

resistance to water;

stability in the cold.

The size of the following types of bricks:

single;

one and a half;

- double.

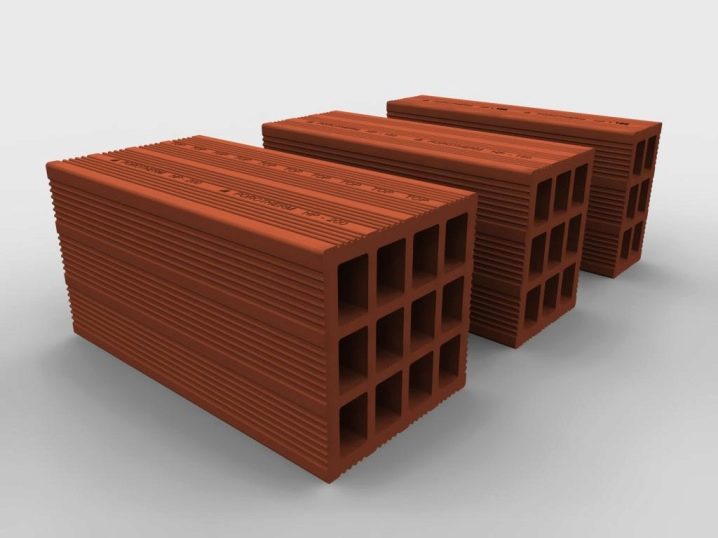

A single product has a dimension of 250x120x65 mm. One and a half - 250x120x88 mm. Double - 250x120x138 mm.The more voids, the easier the molded design. But we must also take into account the effect of the number of voids on the resistance to cold and water absorption. A red building block can have a different shape — a circle, a square, a rectangle, or even an oval.

Categories of building materials

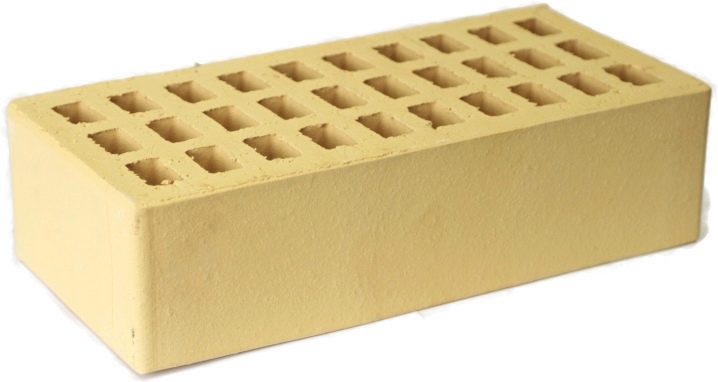

Hollow bricks based on cement and sand are cheaper than the traditional ceramic version. After all, it does not include quite expensive clay. Its absence does not affect the technical characteristics - the product is quite durable. However, such a brick transmits more heat than other varieties. Therefore, it is used sparingly.

Much better in this regard, the so-called heat-efficient material. It is relatively light and allows you to keep the heat in the house in any weather. Ceramic slotted block is widely in demand when facing buildings. It also has an excellent level of thermal insulation. If, along with the retention of heat, it is necessary to prevent the spread of extraneous sounds, it is necessary to use porous brick.

Double slotted brick is popular because of the optimal speed and cost reduction. It also has excellent strength and retains heat well.These valuable properties are preserved even when stacked in one row. The share of the cracks can be from 15 to 55% of the total brick volume.

The most expensive type of slotted bricks is foamyatomitovy - it is needed mainly for metallurgical production, and in private construction almost never used.

Nuances of technology and application

Slit brick is produced with a minimum consumption of primary raw materials. This reduces labor intensity and helps reduce the cost of the finished product. The seven-gage building block has become widespread, but without any particular problems any other number of voids can be obtained. For work clay with humidity of 10% is used.

Receiving voids inside the pressing unit is achieved by using special cores. The important point is the systematic drying of the blocks, which cannot be accelerated. As soon as the drying is over, the bricks are burned, heating them to 1000 degrees. Slit brick suitable mainly for load-bearing walls, the base of it can not be put. But you can lay out the internal walls.

The selection of blocks in size is based on the complexity of the construction and the scale of the work to be done.The larger the structure under construction, the larger the blocks themselves must be. This allows you to speed up the workflow, save on cement mix. Large residential buildings are often built from double smooth bricks. The ban on the use of hollow bricks in the plinths and foundations is associated with its high hygroscopicity.

Practical use of slotted bricks

The laying process does not require the use of any fasteners, with the exception of cement mortar. Each stage of work is performed by strictly defined tools. In order for the stability of the structure to be optimal, it is necessary to wait 2 or 3 days until the coating is dry. The territory where they will build a house must be marked up. In advance designate rows of future laying.

The outer part of the brickwork must have a pattern, otherwise it will not be sufficiently aesthetic. This problem can be solved by jointing (compaction of the solution in them). Immediately when laying the solution is pruned. This greatly simplifies the execution of the work. The seams can be rectangular, oval or round.

For the jointing to be concave inward, the special shape must be convex. But jointing round section done with the help of concave elements. Attention: the brick should keep within relative each other most accurately. Capital walls are mainly laid out from double blocks. If lightweight construction is being built, single products can be used.

Additional Information

Interior partitions, as well as other non-bearing structures are often constructed of cement-sand brick. The lining of stoves and fireplaces is mainly produced by foam diatomite constructions. But the lining is most often porous or ceramic material. According to established standards, the minimum proportion of voids in a slotted brick can not be less than 13%. The term covers ceramic products obtained from low-melting clay of various grades.

The marginal fraction of voids in the slit brick is 55%. For comparison, in a simple ceramic product, this proportion is limited to 35%. The hollow single block of category M150 has standard dimensions 250x120x65 mm. The mass of such a product is from 2 to 2.3 kg. In the thickened version, these figures are 250x120x65 mm and 3-3.2 kg, in the double version - 250x120x138 mm and 4.8-5 kg.If you take a silicate brick, not ceramic, it will be a little harder.

The slotted material of the European format has dimensions of 250x85x65 mm, and its mass is limited to 2 kg. To build bearing structures, use bricks of the marks M125 — M200. For partitions need blocks of at least M100. In the lines of most Russian factories there is a slotted ceramic brick with a strength of M150 and higher. Ordinary material should have a density of from 1000 to 1450 kg per 1 cu. m, and facing - 130-1450 kg per 1 cu. m

The minimum allowable resistance to cold is not less than 25 cycles of freezing and defrosting, and the water absorption coefficient is not less than 6 and not more than 12%. As for the level of thermal conductivity, it is determined by the number of voids and the density of the product. The normal range is 0.3–0.5 W / m · ° C. The use of blocks with such characteristics will reduce the thickness of external walls by 1/3. There is only one warmer material - this is a particularly light insulated ceramics.

Slit clinker for the most part is in the form of a double stone. Such building material allows not to use auxiliary insulation means for walls with a thickness of 25 cm and for internal partitions.The increased thickness of the blocks provides, along with the acceleration of work, the minimal risk of displacement of structures. This additionally minimizes the pressure on the base of the building. Products well survive even the direct impact of an open flame.

In some cases, the laying of a slotted brick is made using special anchors. Screw fasteners will fit (with an additional nut). It looks like a rod of steel 0.6–2.4 cm long. The coupling on such products is movable, and the shank is similar to a cone. The main surface is covered with a layer of zinc.

Bolted in anchors (with the addition of spacers) are mainly made of brass. In addition to the liner, the design includes a nut and bolt. The shape of the bolt can vary extremely widely. And also used a chemical anchor, working through a mixture of two components. The fastener is held in a laying with a nylon sleeve.

You will learn more about the slit brick in the video below.