Masonry technology "In one and a half bricks"

The walls of various buildings are often laid out in a half bricks. If we are talking about the construction of a two-story erection, then here a similar installation scheme is the best solution used by most experienced craftsmen. Everyone can cope with such construction works, the main thing is to act according to the instructions and use good materials. Today we will take a closer look at the difference between brickwork and a half brick, how to cope with it on our own.

Special features

The brick is one of the most popular and widespread materials possessing a set of positive operational characteristics. That is why brick buildings are found with enviable regularity on every street.They can be built not only by an experienced team of craftsmen, but also by the owners of the acquired site themselves. The main thing is to strictly adhere to the instructions and laying patterns of bricks. If everything is done correctly, the result will not make you disappointed.

There are many uncomplicated brick layouts. One or another option is chosen in accordance with the direct purpose of the future construction and skill of the owners. Many users turn to the method of laying a half bricks. If you follow this scheme, brick walls will be very strong and durable. However, experts advise to apply to this clutch in the event that you are not very limited in the volume of building materials, and also plan to build a house in a zone where increased strength is a necessity.

It should be noted that laying in one and a half bricks differs in that it prevents possible delamination of the material from which the wall structure is made.

If you do not pursue the goal of building a real "bastion", then you can turn to another (simpler) way of laying brick blocks.As in the case of other variants of brickwork, the first row plays a very important role in this situation. He must be laid out according to the rules. It is from this fact that the quality of the whole structure as a whole will depend.

Also, do not forget about the quality of the laid corner bases, since they will subsequently serve as the foundations for the construction of walls. When laying a brick and a half should act very carefully and deliberately. You should not make mistakes and neglect the geometry of materials. As a result, this may lead to the manufacture of unstable and short-lived wall construction, which may have to be redone.

How to make yourself?

The wall, basement and any other construction can be made with the use of 1.5 brick masonry without the involvement of professionals. Of course, the result will largely depend on the quality of the work performed. It is necessary to rely on step-by-step instructions to achieve the desired result. Let's get acquainted with all the stages of such work on the example of making a wall of 1.5 bricks.

Preparatory stage

As with any other construction work, the manufacture of brick construction according to the above scheme provides a number of preparatory steps. You will need to buy high-quality building material and prepare a suitable binder solution for it. In addition, you will definitely need to purchase a number of tools and accessories:

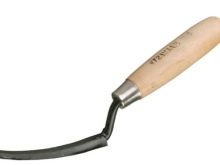

- trowel (otherwise it is called trowel);

- hammer;

- jointing;

- mop;

- plummet;

- level;

- gon;

- cord;

- order;

- roulette;

- the rule;

- pendulum.

Before proceeding to installation, you will need to familiarize yourself with a number of nuances (consider them on the example of building walls):

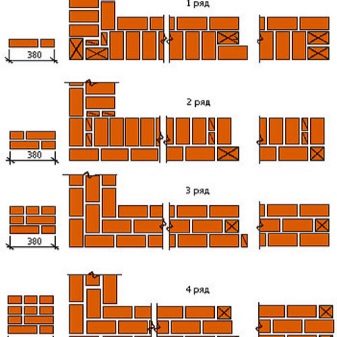

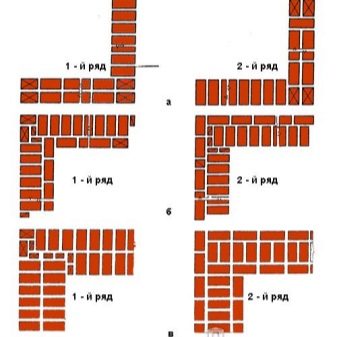

- the thickness of the specified masonry usually reaches 380 mm (this parameter is composed of the parameter of the width of one part, the width of the element joining it and the thickness of the seam);

- it will be necessary to pay special attention to the correct layout of each corner and ligation of the rows;

- for a sufficiently good ligation of 1.5 bricks, full-length, half-quarter, and three-quarter products are required to be used;

- You will need to first mark the location of the 1st row (of course, after choosing the installation technology).

Dressings

Usually masters refer to these types of dressings:

- single row (or chain);

- multi-row.

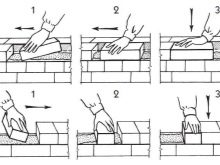

Simple recognized single row ligation. When it alternates tychkovy and spoon rows from the outside of the planned base (if it is a wall). In this case, not full-size bricks in large quantities will be needed.

Multi-ligation is done like this:

- the starting row is laid out "spoon-poke";

- the second is the opposite;

- 3,4,5,6 rows spread spoons with a bunch of stitches in half a bale.

Masonry corners

Angles are the basis for building such brick structures as walls. Even small flaws in the layout here can lead to a serious violation of geometry. Because of this, the carrying capacity of the structure can be significantly reduced.

Note that the installation of corners ahead of the layout of the walls themselves by about 3-4 rows.

This is required in order to be able to install orders and it was possible to stretch a special cord between them. It will help monitor the evenness of the rows in the process of laying out. The technology of displaying 1.5 bricks is complicated when compared with the technique in 1 block.This is explained by the fact that in the first case it will be necessary to use building materials of various formats (fours, three-quarter and half are meant).

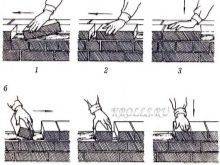

Masonry work

First, you need to waterproof the foundation, laying on it sheets of roofing material. After that, using the construction level in the corners of the future construction, masonry is made in several rows. Corner arrangements with special brackets will then be attached to them. Along the order, you will need to stretch a special cord. He is advised to be positioned every 5 m. If the length between the constructed corners is more significant, then in order to avoid stretching the lace, a beacon of bricks is placed in the middle. After that, it is possible to proceed to the arrangement of brick rows.

Using a trowel, spread the prepared masonry composition. Step from the edge of the wall should be about 20 mm. If the seam is filled entirely, then no more than 10-15 mm. The thickness of the reservoir should be maintained in the range of 25-30 mm. Based on the consistency of the solution, the seams will be 10-12 mm.

Masonry techniques

There are three types of brick laying in 1.5 bricks. Get to know them.

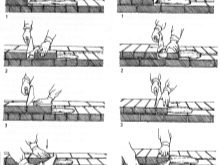

- Come on. This method of laying bricks is recommended to start, if you work with a solid bonding product. At the same time, the seams are completely poured, and their jointing is carried out. To the vertical of the previously delivered block, the rest of the solution is pushed by the trowel. Then put the next brick, which must be pressed against the trowel. Kelmu need to get sharply. The laid-out detail is upset.

- Injection The specified method is relevant when working with plastic composition. In this case, the brick is slightly tilted, it touches the laid solution with one of its faces, advances it to the part fixed before this, and besieges it.

- Sponge with undercut. This technology differs from the above only in that the binder should be laid at a small distance from the edge of the wall. The solution, outstanding outside the joints, then removed with a trowel.

Layout 1.5 blocks can be done with insulation. It is simply attached to the bearing wall base with further plaster coating.

Tips and tricks

Use the tips and recommendations of experts.

- If you doubt your abilities, then experts recommend trusting the laying of corners,piers (as well as zones at the intersection of piers) and such details as poles to masons with extensive experience, since these elements of brick structures are usually extremely important components of the entire structure as a whole.

- Bearing wall with a fixed insulation is permissible to finish a variety of coatings. Plaster can be a rough design, then completed with brick cladding or ventilated facade.

- When preparing a binder solution, it should be remembered that the more cement it contains, the less plastic it will turn out. If you are afraid to prepare the mixture yourself, then it is better to buy an already finished product with consistent proportions. It will only need to add water.

- If the brickwork in 1.5 blocks will be finished off with plaster mix, then there is no need to make jointing of joints in it. This procedure is also not needed if you further want to add the resulting layout with facing brick.

- At each stage of construction work, use the building level. Do not forget that all rows and bases must be as even and correct as possible.

The brickwork "in one and a half bricks" is shown in the video below.