How much does a silicate solid brick weigh?

Silicate solid brick is one of the most popular building materials, due to its high performance properties and wide consumer availability.

Material properties

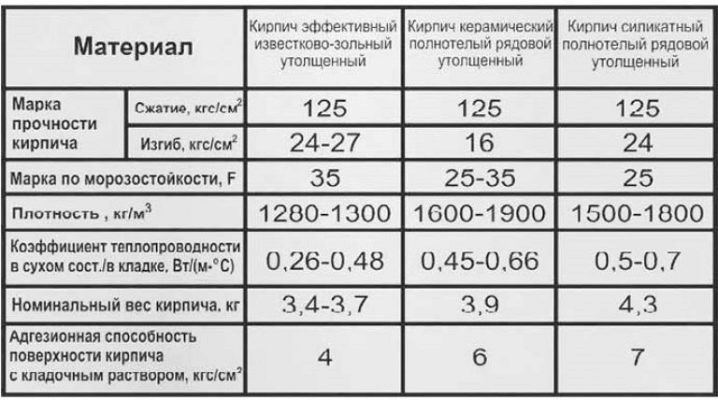

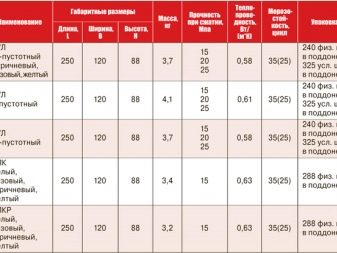

Lime, quartz sand and water are used as raw materials for the manufacture of silicate solid brick. The material has high working qualities, which are clearly defined by GOST 379 95. One of these qualities is the strength of silicate products. This indicator is considered defining. It fully affects the overall reliability and durability of a brick structure, and is indicated by the index M (n), where n is the degree of strength of a particular modification of the silicate product.Thus, the models with the M300 index have the greatest strength; they withstand a pressure of 30 MPa under compression and 4 MPa under bending. Such material is used for the construction of bearing walls of buildings, which later will be a significant weight load. However, it is not used for the construction of foundations.

An equally important indicator of the working qualities of a brick is frost resistance, which is denoted by the symbol F (n), where n is the number of freeze-thaw cycles, which is able to transfer material without losing the main operational properties. The frost resistance of corpulent products corresponds to the F50 index, which is a good indicator and guarantees the preservation of the forms and working properties of the material for 50 years. Porosity and water absorption are also important characteristics of the working qualities of a brick. The porosity of the corpulent silicate is 1500 kg / m3, and the hygroscopicity indices are within 7.5–7.7%.

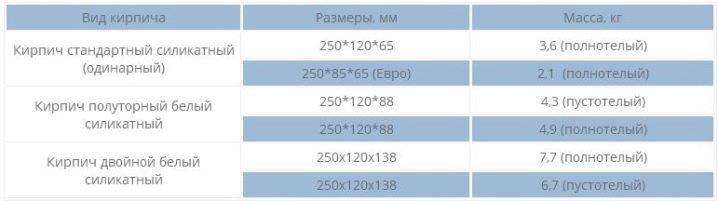

According to GOST standards, solid silica brick is available only in single and one-and-a-half versions, double models of this modification are not made. Brick sizes are also standardized.So, the length of single silicate products is 25 cm, width - 12, and thickness - 6.5 cm. One-and-a-half models have dimensions of 250x120x88 mm. By purpose, there are two varieties of silicate solid brick. The first type includes facing models used for cladding facades, and the second is used for masonry walls and partitions.

Advantages and disadvantages

High consumer demand and widespread use of full-bodied silicate in construction explained by a number of indisputable advantages of this material.

- The complete environmental safety of the material is due to the absence of harmful impurities and toxic additives in the brick composition.

- Low, in comparison with ceramic models, the cost makes silicate brick the most affordable type of building materials used for the construction of buildings.

- Due to the absence of cavities, solid brick has high sound insulation properties, and therefore it is successfully used in the construction of interior and interroom partitions.

- High strength, moisture resistance and frost resistance of silicate products allow construction in any climatic zones.In addition, the brick has a long service life, and buildings built from it look neat and aesthetically pleasing.

The disadvantages include a narrower, in comparison with the ceramic models, the scope of application: silicate brick is used mainly in the construction of the main walls and interior partitions. For the construction of the basement, the foundation, fireplaces, chimney pipes and stoves material is not suitable.

Weight features

The weight of a brick is considered to be a rather important indicator and must be taken into account when predicting the load on the foundation of the foundation, the choice of carrying capacity of vehicles on which the building material will be transported, as well as to determine the type of crane and storage conditions. In addition, the knowledge of the weight of one copy allows calculating the weight of each pallet and the total weight of 1 m3 of silicate masonry with an accuracy of up to a kilogram.

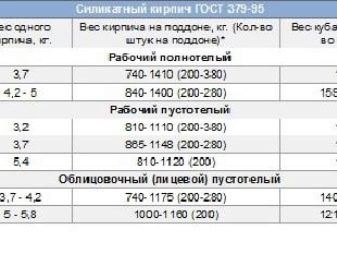

The weight of the white silicate corpulent model of a single version 250x120x65 size is 3.7 kg. Knowing this value is easy to calculate the weight of each pallet, which will vary depending on the number of bricks in it. For example, the weight of a pallet consisting of two hundred products will be equal to 740 kg, while a pallet with 380 copies weighs already 1410 kg. The total weight per cubic meter of masonry is calculated in the same way.The cube includes 513 full-bodied copies, hence its weight will be equal to 1898 kg. However, when calculating the mass of a cubic meter, it is necessary to take into account the weight of the solution consumed for its construction. And based on the fact that the weight of the cement composition of different grades and different consistency is slightly different, you should not take the weight of one cubic meter as a constant value.

One-and-a-half silicate models of full-bodied execution weigh about 4.8 kg. Accordingly, a pallet of 200 pieces will weigh 960 kg, and from 280–1344 kg. One cube of brickwork contains 379 copies, hence its weight without taking into account the mass of the solution will be equal to 1819 kg.

Thus, the knowledge of the weight of a full-bodied silicate brick will help with special accuracy to calculate the weight load of the material on the base plates and will relieve from unpleasant surprises during its transportation and storage.

You can learn more about silica brick from the video below.