Ripped brick: features, varieties and uses

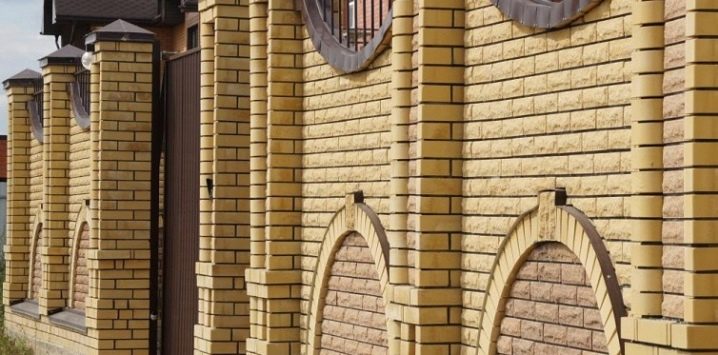

The aesthetic appearance of the facades of houses and fences made with the help of tattered bricks is truly impressive. This facing material looks great in residential interiors, zoning a section of the wall, or decorating a fireplace, arch, columns. It imitates the texture of natural stone: sandstone, limestone, granite. Any construction object lined with torn brick acquires the expressive look and spirit of romance.

What is it like?

The facing brick is called ragged, because one of its sides is deliberately destroyed, giving the appearance of natural material. A wide variety of structures, shapes, sizes and shades helps it to be in demand for various tasks.

The peculiarity of the torn brick is a large weight and density (150-250 kg per square meter). A building with such lining requires a solid foundation, and if the old structure is to be reconstructed, its foundation must first be strengthened. In order to facilitate the task, the builders invented a hollow brick, which by weight is much lighter than full-bodied and can be used in interior design.

Sometimes hollow models are made in the form of a splitter, larger sizes - 39x19 cm, which allows you to make fences and columns much faster.

Manufacturing

For the production of torn bricks do not apply clay and sand, as is done in traditional cases. Raw materials are limestone, shell rock, brick and glass battle, marble, granite chips, screenings of blast furnace slag and expanded clay. The filler is mixed with water (not more than 10%), cement, modifiers and dyes.

Ragged brick is made not by the method of burning, but by the strongest pressing with the maximum decrease in the moisture content of the raw material. Next, the product passes a long drying. The result is bricks that are close to natural stone in strength.

The product is brought to the usual "ragged" type in two ways: simple and complex.

- A simple method cleaves a stone with a machine similar to a guillotine. Each brick is destroyed in different ways, thanks to which the finished masonry looks as natural as possible.

- The second method involves mechanized cleavage on complex equipment. As a result, each brick has the same "ragged" surface. Nozzles allow you to change the structural basis that mimics the diversity of natural stone.

Kinds

Torn brick is classified not only by appearance, it is divided by structure, shape, color, location of the textured cut. For the manufacture of products using manual and mechanical molding. The use of modifiers and plasticizers makes it possible to obtain additional properties, such as resistance to many climatic factors or aggressive environment.

Structure

Facing material is corpulent and hollow, has a different weight and scope.

- The first look is more durable and heavy. It is used where a high load-bearing load is assumed: for facing the basement and the basement, for a solid concrete fence, for laying a fireplace.

- Hollow brick is inferior in strengthbut it is lighter, has good thermal insulation qualities. For facing the surface with similar material there is no need to strengthen the walls or the foundation. Apply hollow brick for interior design, exterior decoration of buildings, fences that are not subjected to special stress.

The form

The standard rectangular shape is used for cladding flat surfaces. But there are also columns, arches, staircases, parapets, cornices, doorways where stone angled, wedge-shaped, twisted or with smooth ends is required. All this diversity makes it possible to maximize the use of tattered brick in facing works.

Textured cut

The cuts on the brick facets of the brick have proven themselves well in facing the openings and corners of buildings. Sloping spoon edges are used for basic design. Angular cuts (45 degrees) are simultaneously on both adjacent sides, such a product is used for cladding columns, window sills, doorways.

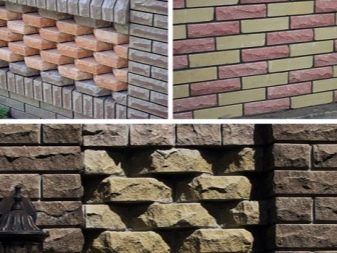

Colour

Color plays a big role in imitating natural material. With its help, it is immediately guessed what constitutes a conventional stone - sandstone, limestone or granite.The added pigment not only colors the product in the usual brown, gray, brick, white or yellow tones, but can make it completely unexpected - purple, khaki or fresh green.

Smooth stone surfaces can be matte or glossy. Good looking glazed bricks.

Positive and negative characteristics

Ragged brick is widely used in the external and internal design of construction objects. It is often preferred to other facing materials, because it has almost no flaws, but possesses an impressive list of positive properties:

- has a beautiful appearance;

- thanks to the strengthened pressing, it acquires ultrastrong qualities, especially it concerns a full-bodied stone;

- durable;

- the brick is resistant to temperature changes, burnout on the sun, mechanical stress;

- it is eco-friendly;

- does not pass moisture;

- fire resistant;

- It does not require special care;

- easy to lay out;

- hollow forms help keep the building warm;

- imitation of natural stone wins in price from the original;

- a large variety of types facilitates the work of designers.

The disadvantage of a torn stone is its vapor impermeability, a property that prevents walls from passing air. Help solve the problem left gaps between the bricks. Sometimes they prefer lighter facing material, for example, ceramic tile.

Scope of application

Ragged brick is used for both external and internal lining. Having a large variety of species, it is difficult to imagine wherever it finds its application. Let us try to summarize the already compiled idea of its comprehensive use:

- most often, a tattered brick is used in the cladding of facades to give the building a beautiful, expressive look;

- the walls of houses do not have to be completely installed with stone, they can be partially decorated, creating a figured frame of the basement or foundation;

- industry produces certain types of bricks for the design of pillars, porches, arches;

- The door and window openings decorated with torn stone look impeccable;

- bricks are used in landscape design for decorating benches, flowerbeds, arbors, patios, barbecue areas;

- it is often used in the design of fences, giving them an expensive, presentable appearance;

- indoors, one wall or a fragment of it is decorated, fireplaces, columns are made up, interior walls are made of solid bricks.

Facing works

The process of decorating surfaces with a tattered brick is quite simple and consists of two stages.

- Training. First of all, the ability of the wall to withstand a heavy load of cladding is calculated. If necessary, reinforce the foundation or the wall itself. Then a flat surface is created for the subsequent work with the material: the gaps are filled, the plane is plastered. The finished wall should be treated with antifungal agent.

- Directly facing. The adhesive composition is applied to the primed surface. It should be remembered about the impressive weight of the lining and not regret the mortar, but at the same time it should not leave the seams, soiling decorative elements. Then everything is simple: a brick is applied, lightly tapped with a wooden hammer, and the remnants of glue are immediately removed.

The process of facing a torn brick is quite simple, and the delightful appearance of the facade will delight for many years.

How masters make a torn brick look in the next video.