How many facing bricks in 1 square. m laying?

The need to calculate the number of facing bricks in 1 square. m masonry occurs in cases where the decision is made to finish the facade of the building. Before the beginning of the formation of the masonry, it is necessary to calculate the number of pieces or modules in one square meter. It may vary depending on the type of masonry used, the thickness of the walls. By calculating in advance how much lining at the house you need, you can prevent possible mistakes in the procurement of materials and ensure their most rational use during the work.

Sizes and types of bricks

There is a certain dimensional mesh brick, adopted in the EU and Russia (GOST). It has differences that are necessarily taken into account when purchasing and calculating materials. In particular, domestic products are more focused on ease of laying with docking on the long sides (spoons) or short sidewalls (buttings). European manufacturers focus on the decorative component of the masonry. Here, it is the individuality of design that is highly valued, and the component parts do not necessarily have to ideally fit one another.

In particular, the European standard allows the following size range (LxWxH):

- 2DF 240x115x113 mm;

- DF 240x115x52 mm;

- WF 210x100x50 mm;

- WD F210x100x65 mm.

Russian standards also provide opportunities for varying the height of each layer of masonry. So, single variants with a figure of 65 mm are distinguished, double ones are 138 mm high, one-and-a-half are 88 mm. The dimensions of the long and short sides for all options are standard: 250x120 mm. When calculating the amount of necessary materials, it is necessary to take into account the chosen thickness of the masonry joint. For example, in 1 m2 of masonry with a mortar - 102 pieces of a single brick, and without counting the jointing, this figure will already be 128 units.

Types of masonry

A great influence on the consumption of material has a choice of pattern masonry. When facing buildings and structures, blocks of different colors are often used, a mosaic ornament or a continuous coating is formed, which is expressive due to the use of an unusual color range of products. Particularly in demand are decorative versions of brick cladding in Europe, where entire collections of solutions for facades in a particular style are produced.

The process of forming the masonry layer itself always involves two components - mortar and brick. But the sequence and method of mounting a solid wall can vary significantly. There are several types of the most popular variants of the external ornament.

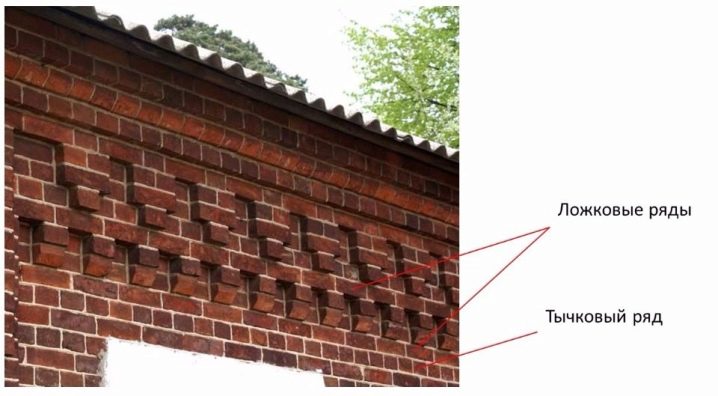

- Block type of masonry. It is characterized by alternating rows with a long and short part of the brick on the front side of the facade. At the same time, the joints coincide, providing the opportunity to create a harmonious facade solution. In the Gothic version, the same sequence of using the long and short sides is made, but with the displacement of the joints.

- Track. The masonry is formed offset by half the length of the brick in each row.The coating has visual appeal. On the front side is always the long part of the product.

- Lipetsk laying. It is characterized by the preservation of joints along the entire height of the outer wall. The rows are combined in the following order: three long elements for one short. It is possible to use modules of different color.

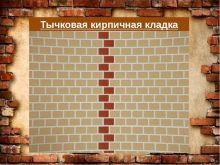

- Tychkovy. On the facade only the short side is used, shifting as the rows are laid out.

- Spoon laying. Formed on the long side (spoon). The offset is 1/4 or 1/2 brick.

- Brandenburg laying. It is characterized by a combination of two spoons and one tychkovy element. In this case, the short side is always shifted so as to be located at the junction of long parts.

- Chaotic way. It allows you to form a facade finish with the help of colored bricks of different colors. The location of the modules is chosen arbitrarily, it does not have a clear order.

In the construction industry, other popular and sought-after mounting options for facade decorative coatings are also used. It is worth paying attention to the fact that when choosing a type of masonry with a clear sequence of elements,it is necessary to carefully maintain the appropriate density and fluidity of the solution in order to avoid possible problems with distortion of the seam line.

Calculation of the area of the walls

In order to calculate the total area of the walls and get the number of bricks necessary for the house, you will have to take some preliminary steps. There are certain standard values that you can consider when you make a request.

For example, the number of products in a pack is calculated based on its height (on average it is 1 m) and dimensions. In the square, the number of bricks is calculated with and without the use of mortar. For example, thin facade cladding of 0.5 bricks in a single version requires the purchase of 51/61 pieces. If the supplier proposes to consider material as pallets, you need to remember that there are 420 standard-sized items placed on the pallet.

When calculating the area of the walls should also take into account a number of factors. So, you should definitely remember the need to accurately measure all the parameters of the facade to be veneered. To get them, you will need:

- multiply the length and height of each wall (performed for objects of any configuration);

- get by adding these values the total area of the facade structure;

- measure and calculate the area occupied by the door and window openings;

- add together the resulting data;

- from the total area of the facade subtract the same parameters for the doors and windows;

- The data obtained will be the basis for further counting the number of materials.

The metric area of all those who need brick facing surfaces will only be multiplied by the number of elements per 1 m2. But such an approach cannot be called completely objective. After all, in the process of work, the jointing, laying out of corners and openings is made, which also requires the use of an additional volume of materials. Both marriage and battle must be taken into account when processing brick blocks.

Ways to count products

Calculate the number of facing bricks in 1 square. m masonry can be in different ways. The number of pieces of building modules depends on how exactly the masonry is made. Cladding is most often done with half a brick because it is fixed around the main wall. But if you want to significantly improve the thermal insulation or sound insulation properties of the structure, you can mount the facade in 1,1.5 or even 2 bricks.

In this case, if there are seams, the number of elements in 1 m2 will be as follows.

Brick type | The number of pieces when laying in 0.5 brick with a solution | in 1 brick | in 1.5 bricks | in 2 bricks |

Single | 51 | 102 | 153 | 204 |

Bastard | 39 | 78 | 117 | 156 |

Double | 26 | 52 | 78 | 104 |

Without the seams, the calculation of brick consumption per 1 m2 of masonry will be as follows.

Brick type | The number of pieces when laying in 0.5 brick without solution | in 1 brick | in 1.5 bricks | in 2 bricks |

Single | 61 | 128 | 189 | 256 |

Bastard | 45 | 95 | 140 | 190 |

Double | 30 | 60 | 90 | 120 |

Influences the number of elements in one square meter of decorative facing and the type of modules used. High double and one-and-a-half options will reduce the consumption of the solution. For single elements, the consumption of the bricks themselves will be higher. For counting it is also worth considering the number of bricks in the pallet.

When ordering material, it is important to know other parameters and indicators of purchased products. In particular, when delivered in bulk or in packs, there are 512 bricks in a cube. It is worth adding that the averaged values in this case should be used only when calculating masonry with the same arrangement of elements (only the spoon or only the edge).

In addition, if the calculation is carried out pieces in one cubic meter of the wall, it is necessary to take into account the proportions of the seam. They account for up to 25% of the total.Work at the standard thickness of the seams allows for a flow rate of 1 m3 of 394 units of products.

Masonry thickness should be determined individually. In the case of the use of double or one-and-a-half bricks, it is necessary to take into account all the indicators associated with a decrease in the amount of material. In addition to the volume, you can conduct calculations based on the indicators of the area of the walls. This will provide a more reliable result. For exterior walls, the error rates reach 1.9%, for internal partitions - 3.8%.

Choosing the method of calculation, it is necessary to take into account all possible aspects related to the performance of work. The length and width of the masonry joints, if it differs from the standard, should be taken into account in the calculations. The number of bricks per 1 m2 or 1 m3 in this case will be less than the average.

Before you begin finishing work, you should take care to purchase the appropriate amount of materials for decorating the facades. The consumption of facing bricks should take into account the thickness of the seams, the area of the walls, the method of forming the masonry. This approach will avoid problems with a shortage of materials.

.

In addition, the calculations should always take into account the battle of the brick in the process. The stock should be about 5%. With the correct calculation of the necessary volumes of material, it is possible to ensure the uninterrupted course of work in the formation of the decorative cladding of the facade of the building.

An example of correct brick calculation in the video below.