Grouting decorative brick joints - all the details of the procedure

After completion of works on finishing the foundation, grouting of decorative brick or other material is necessary, which will make it possible to give a finished look to the masonry and ensure its uniqueness. It’s easy to do this kind of work on your own and you don’t need special education or skills. You can prepare the mixture yourself or buy ready-made in a hardware store. With proper work, the decoration will last on the wall for many years and will not lose its appearance.

Grouting features

In order to fill the gaps between the individual building materials after their installation, you can apply different compositions.When choosing such a composition, it is necessary to take into account the color of the decorative product, the space between its individual elements, the thickness of the bricks and other moments. You can rub the mixtures that differ in different shades depending on the color of the finishing material. And also it is possible to mix various solutions on color, achieving the required shade.

When preparing such a composition with your own hands, you must take into account the characteristics of the masonry and the location of the wall itself. If this is a room with high humidity, it is necessary to use compounds for sealing seams, which will prevent the possibility of moisture between the bricks. For this you can use various additives for solutions.

The advantage of the plaster grout is that the material quickly hardens, but the work must be done carefully so that there is no solution on the face of the brick. Otherwise it will be difficult to scrub or wash it later.

In some cases, rubbing after brick is made with silicone sealant, which usually has no color, but dyes can be added to it.Such a grout after the completion of the work will allow to emphasize the natural color of the finishing material itself and smooth out the unevenness of the seams, if any.

Amount of compound to fill the seams

All work on the grout should be carried out only after the completion of the installation of finishing materials. Reliably and beautifully wipe the distance between the individual elements can, if you follow the rules and regulations. It is also important that the laying itself is carried out at the same distance between the individual bricks, in which case it will be easier to fill the seams.

Depending on the width of the seam and the depth of the laying itself, it is possible to calculate the amount of material required to fill them. For brick seams up to one centimeter wide, it is necessary to spend 7–8 kg of the mixture per square meter. But these parameters may vary depending on the characteristics of the laying.

Grout technology

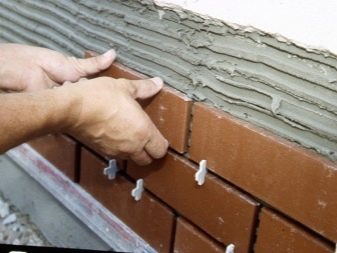

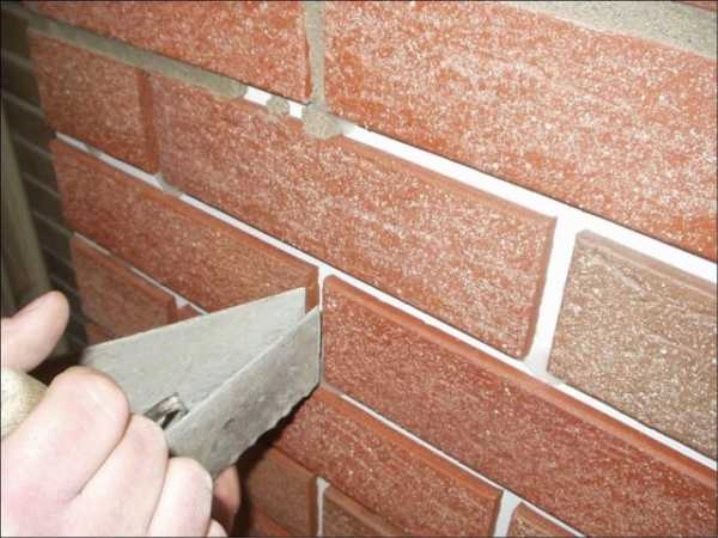

To make all the work, you must have a tool, among which the main is the spatula and a special bag where the composition is placed. But also work on filling the seams can be done with a syringe. The use of these tools will help to quickly treat the seams and not to contaminate the surface of the brickwork.

Depending on which grouting method will be used, it is necessary to prepare an additional tool:

- capacity for solution;

- trowel;

- level;

- mixer.

It is important to initially prepare the surface and clean it from excess solution and dust. The mixture is carefully laid in the seams and compacted, and its excess is erased immediately after application, so that they do not dry out.

You need to choose a mixture depending on the characteristics of their use, and diluted in accordance with the instructions on the packaging. Often such compositions are sold in dry form, they will only need to be diluted with water and stirred. It is better to prepare such an amount of mixture that the master can use during the period of time for which the grout will not be able to freeze. In addition, a stale solution may impair the waterproofing of joints, and cracks will form when they dry.

From this point it is necessary to decide on the stage of laying bricks, depending on why the method of brick laying itself will be chosen. Each of the grout technology has its own technique of execution, and therefore it must be adhered to throughout the entire time of work. Usually grouting is done in several ways.

- Flush. This is the easiest option and it is performed with a semi-dry mixture. It can be made by hand. The composition is applied between the bricks with a trowel, and its excess is removed. At the end of the work it is necessary to wipe the surface with a hard cloth or a brush in order to remove the excess.

- Inside All mortar, which remains when brick is laid between them, is tamped and, if necessary, additional recesses are made. This will create a concavity of the seams, and the bricks will protrude outwards.

- Convex To do this, use a special spatula, which is carried out on the seam filled with mortar. Thanks to this method, the seams go outside. But the process requires certain skills. Not everyone can handle it.

- Triangle. Quite a complicated process and it is often used for grouting indoors. To carry out the work, it is necessary to remove a small amount of mortar between the bricks, and distribute the remaining composition with a triangle. This technology requires a certain experience from the master.

- Under the bevel. This method is simple and does not require skill.It is necessary to move the trowel along the seam and remove part of the solution, making a small depression up to 4 mm at a certain angle.

Specialist recommendations

So that during the work there are no defects and errors, need to read the recommendations from the masters.

- When preparing the composition for grouting, it is necessary to use sifted ingredients so that they do not have large fractions.

- After preparing the solution, it should be allowed to stand for 10–15 minutes, and then mix again to improve ductility.

- When grouting, avoid applying the mortar to the bricks.

- If the solution got on the decorative finish, it must be immediately removed, not allowing drying.

SNiP indicates that the seam thickness should be up to 1 cm, and therefore it is recommended to make small gaps between the bricks themselves, adjusting the value depending on the climatic conditions at the work site. There is no need to start grouting on hot days, as the solution will harden quickly, which can lead to a disruption in the process. And it is also worth refusing to work in wet weather.It is necessary to knead the solution in small portions in order to produce it quickly and not allow it to freeze.

As can be seen, the grout is a responsible, but effective way to improve the appearance of the ceramic or other coating after the finishing works, and also it will give an opportunity to create the completeness of the work. Professionally produced grout will improve the appearance of the base and will protect the wall from damage. In addition, it will increase the insulating properties of the masonry, which will allow it to stand for a long time and not require annual repairs. To do this, you only need to perform all the work according to the recommendations and the capitalized rules.

An example of grouting you can see in the video below.