Features of polyurethane primer for the floor

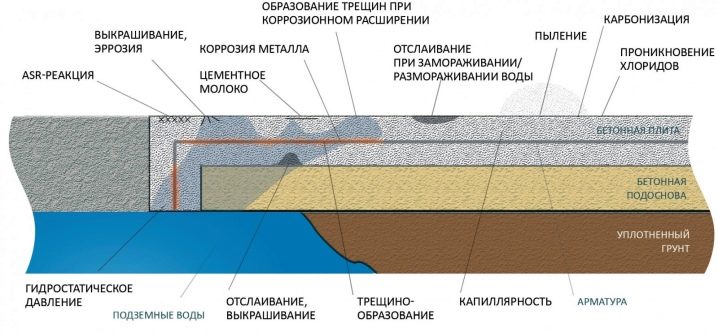

Concrete, despite its high mechanical hardness and density, is a porous material. The presence of such a structure leads to the absorption of moisture from the environment. The increased absorbing capacity of concrete foundations that have not undergone additional treatment with a primer for concrete, leads to an overrun of paintwork materials in the process of finishing works on them.

For this reason, the surface of the concrete floor is covered with a layer of primer. It is a special compound that has the ability to penetrate deep into the base of concrete. Filling the micropores of such a floor, the primer helps to strengthen the concrete surfaces, while enhancing their adhesive ability.

Types of primer coatings

The modern market offers consumers a wide range of ground coverings. All these finishing materials must have the necessary strength of adhesion to the concrete surface and the ability to improve its structure.

All primers and their zinc-rich variety, in particular, differ in composition and purpose.

In composition distinguish:

- Adhesive primer, creating a top coat with a rough surface. This feature contributes to a better setting of finishing building materials with a smooth concrete surface;

- Epoxy, designed to resist external factors and is able to fill small pores in concrete, creating a flat surface and strengthening it;

- Polyurethane, having a similar to the epoxy principle of action. It primes concrete floors for industrial premises;

- Acrylic, eco-friendly primer without odor and release of substances harmful to humans. It contains a fungicidal component to prevent fungal mold accumulations. Its structure helps to reduce the consumption of finishing building materials. The undoubted advantage of acrylic primer is its small price.The maximum drying time is 3 hours, which makes it possible to continue repair work soon;

- Silicone for priming the floor in rooms with high humidity;

- Primer brand "Concrete Contact". This coating is applied before laying a new ceramic tile or processing plasterboard sheets.

To destination differ:

- antiseptic primers that protect against mold and mildew;

- anti-corrosion;

- insulating primer mixtures for protection against chemical aggressive compounds and adverse environmental factors;

- priming compositions to improve the connection between two different materials;

- compositions for priming the surface of aerated concrete.

There is also a classification according to the type of surface to be treated; it includes primers for smooth concrete surfaces that will be painted, plastered, or waterproofed.

Another type used for porous concrete surfaces are those that fill these pores with silicate fillers.

Another type of primer - alkyd, it is designed to work with metal. It is also used on concrete, since in both cases it has a very high level of strength, cannot be erased after solidification, and can be used in the cold. However, the disadvantage is a long, about 12 hours, drying time.

Criterias of choice

A competent choice of soil mixture should include the use of such its brands, which include an antiseptic to prevent the appearance of fungi and mold, especially in rooms with high humidity levels.

For indoor concrete foundations of premises used conventional primers, and for the outer part of the basement the best option would be a mixture specially designed for facades.

When making a purchase, pay attention to the time of manufacture and the integrity of the container. Overdue goods, as well as damaged packaging can cause loss of useful properties of the primer.

Ways to apply primer

The primer coating is applied in 2 layers with waiting time for each to dry. This work is carried out in compliance with safety regulations. Be sure to use a respirator, goggles and gloves.It is important to consider the required temperature conditions, which are indicated on the product packaging.

Primer compositions can be sold in finished condition or in dry form for further dilution with water.

In the latter case, the mixture is prepared immediately before performing repair work:

- The surface to be cleaned is cleaned from dust, dirt and grease stains manually or with the help of a grinder.

- The composition is applied with a brush, roller or spray gun.

- Application of the soil to the concrete is carried out in one or two layers, as indicated in the instructions for this brand of mixture.

General recommendations

- Before buying a building material, you should consider the area of its application, for which works (external or internal) it will be used.

- It is necessary to pay attention to the quality of the treated surface, its service life, the presence of pores in it, what kind of finishing method will be applied to this concrete floor.

- It is necessary to determine the level of solar lighting, state of humidity and other environmental factors. After that, the material consumption is calculated per unit area of the treated surface, that is, per square meter.

Benefits of using primer composites for concrete

By taking into account all the properties of primer coatings for concrete foundations and recommendations for their choice, you can get the most even surface. Concrete begins to interact better with any finishing material. The service life of the floor treated with a primer mixture, significantly increased by giving its surface improved adhesion properties.

The finishing material adheres more firmly to the concrete, which helps prevent the development of delaminations from it, cracks and subsequent destruction.

The concrete floor surface itself is significantly hardened after such treatment, whereas without it a small layer of concrete under a decorative coating can quickly collapse. Processing the concrete base with an appropriate soil composition greatly contributes to its protection against aggressive chemical compounds, which, together with dampness, are able to penetrate even under a layer of putty.

The primer securely closes the micropores in the concrete layer., thereby contributing to a reduction in the consumption of finishing materials.This treatment method preserves the natural moisture level, since non-grounded surfaces are always either overdried or, on the contrary, excessively moistened.

The latter circumstance negatively affects both the quality of the finish and its durability.

See below for how to prime the floor.