Should the walls be primed before plastering?

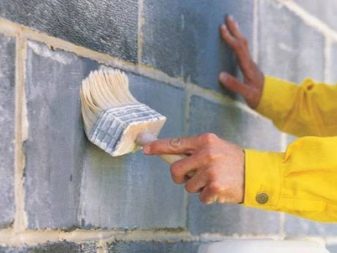

Plastering walls in the process of repair is one of its most important stages. On how well you do it, depends on the durability, strength and aesthetic appearance of the finishing coating: wallpaper, paint or tile. Sometimes the plaster itself begins to crack and fall off. Pre-coating the walls with a primer can save you from a lot of problems and extra time and money.

What is it for?

Is it necessary to ground the walls and is it possible to do without it - a question of interest to many people starting repair. Can highlight several important functions that the primer performs:

- strengthens the crumbling and porous surface of the base of the walls;

- improves the adhesion of the plaster and the previous layer;

- reduces the risk of moisture from the wall to the decorative layer, that is, acts as a waterproofing;

- the composition of priming mixtures includes special additives that provide an antiseptic effect (resist fungi and mold, which is important in wet rooms) and increase the fire-resistant properties of plaster;

- improves the quality of the surface, as during its application fine particles and construction dust are scrubbed from the base;

- any formulations applied to the primer, fall more evenly;

- protects the finish from various stains that may appear from the walls.

From all of the above, we can conclude that the treatment with a primer before plastering is required.

Kinds

The primer can be subdivided, depending on different indicators. One of them is the impact feature. Mixtures differ in composition, and each additional ingredient affects certain properties of the final product:

- Adhesive composition used for better contact with materials that poorly absorb moisture. These include plastic, glass, tile or metals.Dense coatings are not able to grapple with plaster.

- Deep penetrating mixture. It should be used for porous substrates, such as concrete, drywall, brick, and plaster walls. The composition increases the strength of the wall, saves plaster consumption by reducing its absorption.

- Insulating compounds. The need for their application arises when there are visual color defects on the basis of the walls: various stains, rust and paint.

The primer forms a layer that does not allow contaminants to tread on the finishing material or can be used to separate the layers of the draft and topcoat.

- Anti-fungal and anti-mold compounds. First of all, their use is justified in bathrooms, bathrooms or kitchens and other rooms with high humidity. They will prevent damage to the walls from microorganisms and guarantee a healthy environment in the rooms.

- Universal primer combines several types to improve the quality of the base and facilitate the application of plaster on it.

The compositions of primers are different, in this regard, there are several types:

- Acrylic formulations.This is a universal type of primer used for various types of surfaces and for many finishing coatings, including emulsion paints. Ecological properties of acrylic cause the popularity of the application and give advantages to the composition: it dries quickly, has no odor, increases adhesion. Such mixtures are not suitable only for metal substrates: they can contribute to the appearance of rust.

- Alkyd primers have sufficient versatility for use on different types of bases. The only exceptions are walls made of porous materials with high absorbency: concrete, brick, drywall, etc. If phosphates are included in the mixture, then it should be used mainly under acrylic paint.

Glyphthalic subspecies is used mainly for dry spaces. They are covered with hydrophobic materials (resistant to moisture).

- PVA soils. Many people try to prepare such solutions by themselves. They have several disadvantages: they provide insufficient adhesion, they can contribute to the detachment of plaster in violation of the proportions of the batch, they can cause the appearance of yellow spots on the finish.

At the same time, there are several advantages. The cheapness of the composition does not allow him to lose demand for repairs. The adhesive backing forms a waterproof film on the wall surface.

- Mineral solutions. They are intended for porous substrates: gypsum, concrete, walls of gas silicate blocks, bricks or covered with a layer of plaster.

Their main task is to reduce the moisture absorption of the surface, and consequently, saving the applied solution. This is especially true before wallpapering or applying decorative plaster.

- Polystyrene primer. Use it for wooden and plastered walls. But indoors such a composition can not be used because of its toxicity.

To improve the properties of various types of primer mixtures can be added components that form a film layer or accelerate the drying of the surface. In the characteristics of the primer, the type of substrate is often mentioned. Therefore, it is appropriate to separate the primer materials for:

- wood;

- metal;

- glass;

- plastics;

- mineral bases.

Surface Features

The optimum choice of primer is due to differences in the properties of the bases.For each surface, it is necessary to select the type of mixture that will best prepare it for the application of plaster and ensure the durability of such a coating.

There are several groups of wall surfaces:

- Metallic surface. In the apartment you are unlikely to meet this type of material, but in a private house it can be gates, garage doors, and various partitions. If you need to plaster them, you should use a primer that protects against corrosion.

A rust converter is often used on metal for this purpose. It will also cope with an increase in adhesive characteristics.

- Hydrophobic types of grounds. This group includes glass, plastic, laminate, tile. Before applying the plaster, they must be processed to improve the adhesion of dense and smooth materials with the next layer. In order to form a film on the surface, you can use primer mixtures with the addition of resins or PVA. Then it will be much easier to apply paint or plaster.

- Wood surfaces have two significant drawbacks: they burn easily and are exposed to various microorganisms.This applies not only to natural wood, but also to chipboard, wood-board and blocks of pressed chips. Properly selected primer mixes will increase the safety of coatings and protect against mold in case of high humidity.

- Loose and porous surfaces. This group includes walls of foam concrete blocks, aerated concrete, brick, concrete. The structure of the materials will contribute to the excessive absorption of moisture-containing mixtures into the surface of the walls. Therefore, it is common to apply a primer, which forms a special protective film, on brick foundations or walls, the basis of which is a gas block.

It is better to use this composition if you are going to plaster the wall on which the putty has been applied.

Which one to choose?

For the most part, before plastering walls you need to solve only two problems: how to strengthen the surface and ensure the durability of the coating with a smooth base. In the first case, primer mixtures of deep penetration form a film, which, when heated, begins to emit a characteristic odor. Among the mixtures for smooth bases is widely distributed concrete contact, containing adhesive additives.

In the case of the preparation of ceilings for plaster, traditionally, deep penetration, acrylic or mineral soil is used. In the old houses can be found bleached ceiling. If it is coated with lime, it is sufficient to remove it with a damp cloth and proceed with the priming. In the case of working with a chalk base, the primer should be applied twice.

After the first layer it will be seen what quality whitewashing on the surface. If nothing is damaged, you can use special compositions for whitewashing. In case of defects, it is better to remove the entire chalk layer.

The success of your repair will depend on the quality of the primer you choose. Therefore, the store should pay attention not only to the composition and purpose, but also to the manufacturer

If you are not particularly versed in building materials, you should study the products of brands:

- Knauf. This is a German manufacturer, guaranteeing the appropriate quality and improving its manufacturing technology for building materials since the first half of the last century. The range of primers includes compositions of deep penetration, and universal acrylic, and betonkontakt, and even solutions for decorative plaster.

- Tikkurila. Finnish sales leader of paints and finishing materials, known throughout the world.Selecting different primers will allow you to choose the most suitable mixture for solving a specific problem.

- Ceresit - Another high-quality German brand, produced by one of the world leaders in the production of various materials Henkel. The company constantly applies the latest technology, expands the range and works on pricing. The cost of production remains acceptable due to manufacturing in Russia. Four types of soil are most popular: deep penetration, under decorative plaster, concrete contact (can withstand temperatures of -40? C) and antifungal.

- "Miners" - Russian company that has been developing various construction materials for more than 20 years. A tempting price tag combined with a decent quality, according to customers and a wide range of primers make it a serious competitor to foreign counterparts.

- Bergauf - the result of investing funds from Germany in order to create plants of dry mixes of German level in Russia. The history of the brand does not have two decades, but it has already managed to gain the trust of customers. The line includes 4 product options: deep penetration primer, adhesive, universal and for external and internal surfaces (frost-resistant).

Usage tips

Below are a few recommendations that can help avoid common mistakes when working with primer mixtures and in some cases save time and budget:

- Any substrate before priming must be carefully prepared. From the brick wall scrape away all the hillocks of cement. Concrete dedusting and leveling. Wooden bases are cleaned of dirt and dust. If a large layer of plaster is required, fill a grid of thin slats for greater adhesion.

- Sometimes you can use other types of solutions instead of primer. If you mix the PVA and sand to a state of a light homogeneous slurry and apply on the cement base, you can safely lay the tile on such a coating. It is better to refuse use of paints on a water basis instead of priming mixes. Adhesion properties in this case will be low, and the moisture barrier is ineffective. Instead of saving, you get poor strength and high consumption of plaster.

- In the case of working with wooden walls and ceilings, it is definitely better to resort to shop products. At home, you will not be able to pick up all the necessary anti-mold and firming additives in the right proportion, and the risk of damage to the coating will be great.

- In the process of mixing the primer, strictly follow the instructions on the packaging. This will ensure the quality and durability of the finish coating.

- If the surface is very loose and porous, the mixture consumption may increase in relation to the specified by the manufacturer. Therefore, it is better to always take a primer with a small margin.

- Do not use a mixture of primers from different manufacturers. This will violate their stated qualities and functions.

- In conditions when it is necessary to choose a certain shade to cover the wall, you can use special formulations containing colored pigment. And the primer, and Kohler better to purchase from one manufacturer. This will provide better interaction and reliable results.

In the next video you can learn more about the primer.