Acrylic primer deep penetration: what is needed and application technology

Having decided to finish the walls, ceiling or floor, I want to do the work as practical as possible, even if the work surface looks old and porous. Wizards easily cope with this, as the secret of success is concentrated in the use of special tools for surface treatment. We will understand together in the appointment of acrylic primer deep penetration and technology of its application.

Special features

Acrylic primer of deep penetration is a special material for surface treatment before the execution of finishing works, in finished form with a consistency resembling milk.

The color can be different: more often it is transparent, sometimes white, pinkish, light gray. This primer is one of the varieties of acrylic primer. It is not a universal means, so the purchase of material should be based strictly on the appointment of the drug.

Today, no one type of finishing work can do without such a primer. The material is a little sticky, if you do not immediately wash it off from your hands, it is removed with difficulty.

Sold primarily in cans and canisters. Volume depends on the standards of the manufacturer. Most often, such compositions produce a volume of 10 liters.

In case of contact with eyes, rinse immediately with plain water. The skin of the hands does not corrode, depending on the base, it can be odorless, eco-friendly or with a slight specific odor that does not interfere with the work process.

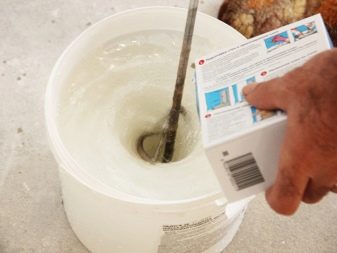

This material is sold as a dry mix and ready-to-process solution. In the first case, it is a powder that must be diluted with water according to the instructions.

The water used is cool: the performance characteristics of the building product will suffer from hot. This is convenient, since such material is usually sufficient for processing the floor, walls and ceiling of a spacious room.

Leftovers can be stored for 12 months., tightly closing the lid and removing the raw material in a dark place.Keep it in the cold is unacceptable. Shelf life of acrylic primer deep penetration is 2 years from the date of issue. Masters do not recommend using it after the expiration date.

Advantages and disadvantages

Acrylic primer of deep penetration has a lot of advantages. Such a tool strengthens the base, making its structure strong enough. It is possible to use this structure for external and internal works. It is suitable for the most unreliable grounds, which apparently do not inspire confidence in the success of cladding. This primer has a high viscosity. Its convenience is water solubility.

The use of acrylic soil allows you to save on the amount of adhesive or paint: the treated surface no longer absorbs the liquid in a large volume, so it does not dry quickly and allows you to carry out finishing work carefully, without haste.

After treatment with this primer of dark surfaces, the paint falls evenly without undyed areas, stripes and other defects. In this case, the gloss of the surface is more pronounced. With regards to the other components of the finish can be noted: the application of tile and wallpaper glue after applying the soil becomes more uniform, which simplifies the finish.

Latex primer has vapor permeability. Despite the fact that it penetrates deep into the base and strengthens even porous surfaces, microorganisms and mold will not appear on it. At the same time, the primer itself after application does not slow down the facing work: it dries quickly even at normal room temperature. Drying time can be different, as it depends on the type of solvent used (fast, slow, classic).

The disadvantage of acrylic primer is some inconvenience of dilution of concentrate, which is not pleasant to everyone. Basically, newcomers complain about this, who are afraid to accurately recreate the desired consistency, which leads to an increase in soil consumption.

Despite the fact that a primer can treat a different type of surface, not every compound is suitable for treating dark metals. Therefore, the use of this tool when facing is permissible only if the desired type of surface is in the list, marked on the packaging.

What is it for?

Acrylic (or latex) primer is suitable for surfaces of different composition. The effect of the material is based on imparting the machined plane to high adhesion withsubsequent applied material. It is necessary in order to keep the finish on the surface as long as possible.

This soil does not just treat the top layer of the base for finishing: it penetrates to a depth of 5 to 10 cm deep into the plane on which it is applied.

The action is based on penetrating ability, which allows you to strengthen the walls, made by the developer in violation of technology. This is more often concrete walls or plaster, in which sand is noticeably more than the norm. Such surfaces peel off, which complicates the process of finishing and may affect the final result. The action of acrylic soil allows penetrating deep into cracks and problem areas of surfaces.

The material binds not only microcracks: it connects the dust and forces all areas of the surface with the risk of poor strength to retain the facing material as much as possible. At the same time, it doesn’t matter at all whether the wallpaper is ceramic, ceiling tile or self-leveling floor. An interesting feature is the formation of a rough mesh on the surface during solidification, which levels the base, making it ready for subsequent processing.

Acrylic primer is suitable for processing cement-concrete screeds, it can handle wooden, plaster types of surfaces, limestone. It will glue the smallest particles of the base, will help prevent the formation of blue and rot.

This primer is protected from damp. You can use it when preparing the surface for parquet, enamel, marble chips, structural plaster. Everywhere she will reward a solid monolithic foundation.

Application technology

Applying soil to the surface is easier than it seems at first glance.

When working you will need:

- foam roller;

- flat brush;

- small flat brush;

- gloves;

- flat tank under the primer.

In the case of a dry concentrate, this set should be added to the container for the breeding material, which is bred strictly in the proportions specified by the manufacturer (usually 1: 4).

Stirring is carried out until the composition becomes homogeneous. In this case, a mask may be needed to prevent the dry compound from entering the lungs.

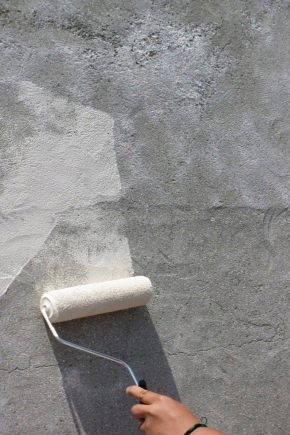

After preparing the necessary equipment and the primer itself proceed to surface treatment.The soil is poured into a flat container, approximately 1/3 closing the roller placed in it by volume. You should not pour more: the solution will drain off the roller in large quantities, which is inconvenient when processing surfaces of walls or ceilings. The roller is convenient because with its help the time spent on surface treatment is halved.

Fill the walls is not necessary: the primer and so high penetration. However, it is not necessary to save either: the main thing is that there are no splashes when rolling the surface. The movements should not be sharp: this is especially true if the repairs in the room are partial. If the soil gets, say, on the wallpaper, they may be stained.

The solution is collected on a roller and rolled them surface for further lining. Since in any job one cannot do without handling the corners of the joints and uncomfortable places, the working tool is changed to a brush of the desired size. The roller does not cope with the accurate processing of the corners: usually in this case it is impossible to avoid stains on the walls.

The brush will avoid unnecessary consumption, make the processing more accurate.

When all the planes are processed, you must immediately remove the remnants of the primer from the tools and containers.If you leave it for later, foam and bristle brush will be oak. After they freeze, the brush and foam coat will have to be thrown out. In the process, the material should be poured into the container little by little: it will not be possible to pour the remains back into the common canister (they will have the smallest dust particles or microfragments of the cement screed).

Ground surface twice. In this case, the reapplication of the soil is possible only after the first layer has dried.

What to consider?

So that the finishing work is not complicated because of the choice of the wrong primer or its incorrect application, it is worth considering a few recommendations.

Experts recommend when buying pay attention to shelf life. If it is less than a month before its end, but the product can obviously remain, either take it back to back with the re-purchase, or choose a material of another brand.

It is preferable to use the soil of a proven company with a good reputation: cheap varieties do not have good viscosity, they will not be able to create a strong crystalline grid and level the base at the proper level.

To ensure maximum adhesion, before applying the primer itself, the surface must be rid of dust, dirt, and especially grease stains that impede high-quality finishing.Distributed by means of the roller on the surface of the facing fabric, dust, grains of sand will prevent further sticking of wallpaper, causing small bubbles under the wallpaper.

It is possible to make facing after full drying of the second layer of soil. This is because when it touches the surface it does not stick. Ground the walls before processing. If repairs are not planned for another month, there is no need to apply a primer in advance.

It is impossible to treat the floor with a primer if it is not prepared and there are significant cracks: this will cause the composition to leak. He will not fix big problems, for this purpose it is necessary to use cement composition.

See below for instructions on applying a deep penetration primer.