Acrylic primer: product features and all the subtleties of choice

Carrying out repair work according to the rules allows to significantly improve the performance characteristics of finishing materials. The focus of the acrylic primer, which today masters emphasize. To understand what attracts this material to professionals, let us examine its features and examine the subtleties of choice.

Special features

Acrylic primer is a building material for processing vertical and horizontal planes, which is necessary for maximum adhesion of the facing material to the treated surface. In other words, the primer allows the wallpaper, tile or other materials to hold firmly and securely, excluding the lag of finishing building materials from the treated base.

It is used for walls, floor and ceiling, treating the surface for about a day for gluing, laying or painting. With the advent of this material, the possibility of decorating has increased significantly. Today, processing of planes with decorative plaster, putty, and paint can not do without it.

This is especially true before installing the floor: for example, an epoxy self-leveling floor, the base of which is not treated with a primer, will quickly lose its visual appeal, and flaws are possible at the very moment of installation. This material is used not only for interior decoration: such a reinforcer is good for carrying out exterior works (for example, for processing a facade). The consistency of the finished liquid resembles milk. During processing in some varieties may be a slight smell.

It is sold more often in banks and canisters of various sizes, this allows you to choose the optimal amount of funds for processing the required area. Often masters buy large cans, which eliminates the additional purchase of material if necessary.

The color of the primer depends on the brand of manufacturer. The product has a certain viscosity, when it comes into contact with the skin it is difficult to wash it off, if you do not do it right away.

Advantages and disadvantages

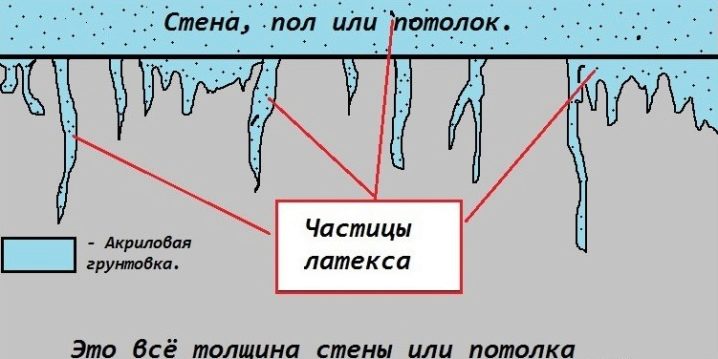

Acrylic primer has a lot of advantages. It is a solution that does not simply connect the finishing material with the treated surface. This repair component is distinguished by deep penetration - depending on the type, the plane is processed to a depth of 5 to 10 cm. The primer is necessary to strengthen the base and make it durable. Even loose walls, which are characterized by porosity, become more uniform and denser after processing. If the composition has thickened, it can be diluted with ordinary water without loss of quality characteristics.

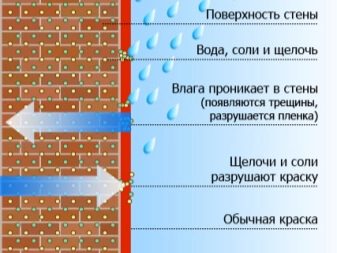

In addition to adhesion, this composition contributes to the fact that the walls absorb less moisture, this is important when pasting them with wallpaper. Reducing the absorbency of the base allows to reduce the consumption of applied finishing material. This has a noticeable effect on such building materials as self-leveling floor, wallpaper paste, and even paint, for which the use of a primer allows for greater gloss.

Moreover, the surface treatment of the base with a primer allows to paint the dark bases of the surface with light tones of paints.

This material does not reduce the vapor permeability of the surface. In the process of drying, a crystal lattice is created on it, which performs the function of a frame holding the finishing materials. Along with the formation of mesh acrylic the primer protects the surface against harmful microorganisms. This fluid is also active in interaction with the surface, on which there are minor impurities that impede the finishing of the plane. Soil eliminates the negative effects of pollution.

In the case of paint after applying a primer, the appearance of divorces, gaps and visible problem areas is minimized. It is noted that paintwork materials applied to the surface treated with acrylic primer, much easier and more convenient.

This drug dries quickly, so it does not slow down the repair process. Such a primer is suitable for the chemical composition of the main part of the facing materials, it is distinguished by its hydrophobic properties, which makes it possible to apply wallpaper glue and paint as evenly as possible.The disadvantage of acrylic primer is the impossibility of coating the surface of ferrous metals.

Of the other disadvantages can be noted the greater consumption of concentrated material, which requires a clear match between water and the mixture. Some species are not environmentally friendly. Therefore, in addition to exterior works, their use is unacceptable. Universal composition can not fully ensure the characteristics that are inherent in each particular type.

Acrylic primer differs in dispersion from 0.05 to 0.15 microns. This allows the particles to penetrate as deeply as possible, giving the treated surface uniformity.

Some varieties allow the addition of special acrylic paints (no more than 15% of the available volume).

The type of solvent used can be of the usual, fast, slow type of action, which explains the different degrees of drying of the primer. Shelf life is 2 years.

The texture of the primer is matte. On average, 1 l is enough for 8-9 l square meters (with 1 processing layer). However, this figure may vary depending on the type of base: the more the walls absorb, the more primers will go.

This material loses its properties in the cold. In the cold store acrylic primer can not. The total shelf life should not exceed 1 year. It is necessary to put means in the place inaccessible for children. If the primer gets into the eyes, they should be immediately rinsed with water.

This auxiliary material prevents drying of mortar mixes, eliminates the formation of air bubbles on the leveling layer. The application is suitable for cement-concrete screeds (including heated options), ceramic and silicate bricks, wood, metal (iron ore), gypsum plasters, lime.

Polyacrylic varieties, characterized by high covering power, prevent the appearance of blue and rot, helping to protect against moisture. They are good as a base preparation for parquet lacquer, various enamels, oil paints, marble chips and structural plaster.

Kinds

In fact, the acrylic primer can be called universal. It is the final stage of surface preparation for dispersion paints based on acrylic, drywall, brick and GLV. In its composition can be used a different type of solvent.

For example, water-dispersion varieties are designed for indoor use. They have no characteristic smell and are harmless type of raw materials. Organic analogues emit resistance to weathering, so this material can be used to prepare the planes for the facade. The use of this solution will protect the surface from mold.

Conventionally, the acrylic primer can be divided into four types:

- penetrating;

- deep penetrating;

- firming;

- adhesive.

At the same time acrylic primer of each type is different. The difference is manifested in the capabilities of each type, color, method of preparation. There are not only universal varieties of such material: today in the construction market you can buy special primer compositions for concrete, walls and wood, as well as anti-corrosion options.

The release form of the acrylic primer is divided into 3 types:

- dry concentrate;

- ready solution;

- mix in a barrel.

The concentrated solution of the strengthening acrylic soil needs to be diluted to the necessary consistence with usual water. This technique allows you to save on the purchase of a solution and carry out surface treatment (walls, floors, ceilings) without thinking about the possible shortage.The classic option is convenient for those who are not accustomed to prepare their own solution. The can is economical.

What is the difference?

The difference between species is obvious, as they differ in the type of impact:

- The first category stands out due to less penetrating power. The main focus of the action is on the surface itself. Such material is convenient where there is no significant need for deep impregnation. The impregnating composition clogs the pores and microcracks of the wall (floor, ceiling), which leads to the same absorption of the base at each site.

- The second species is different viscosity level. It is best used for unreliable grounds. In particular, it can be planes erected in violation of technology, for example, it can be concrete or plaster with a predominance of sand. Such a basis is frayed, so without solid preparation to do something with it for a long time will not work. The tool has a high price, this contributed to the appearance of a mass of cheap analogues, which makes it difficult to choose a quality tool.

- Reinforcing primer has the maximum effect.It is designed for the most problematic and weak surface types. Such a variety does not only deal with cracks: it is able to bind dust and works in relation to poorly supported base places.

- Adhesive acrylic primer has its differences: after processing, it leaves on the basis of a fairly dense film with a characteristic roughness. Unlike previous analogues, this acrylic-based antiseptic primer is characterized by the ability to level the base, preparing it for the finishing facing.

Volume

The volume of acrylic or latex primer depends on the generally accepted standards of manufacturers. Today it is sold in cans, buckets and cans.

Depending on the standards of manufacturers, the volume can be 1, 2.8, 5, 7, 10 l. Soil for plastic is minimal: the cylinder lasts for 2.5 square meters. m. Raw materials in a 10-liter canister is enough to handle the walls of a small kitchen for 2 times.

Colors

The color of the latex primer depends on the technology of the manufacturer. In the classic version, the solution is clear (colorless). Among the varieties there are materials of white and pink color, which is associated with the development of a material with an emphasis on light and color resistance. Some products are distinguished by a light gray tone.

Which is better to choose?

Choosing a type of acrylic primer, it is worth considering several criteria. This will help to understand exactly what type of material is worth buying.

- Choose products of a proven brand. Cheap materials are not always able to handle processing at the proper level.

- Aerosol is worth considering only if the minimum amount of work is planned, a slight correction of the damaged area is needed (for example, you need to change the area of contaminated wallpaper, dismantle the damaged tile).

- After examining all the varieties, give preference to a narrow profile, determining the type of surface. The universal variety from each species took a little, it will not give the proper level of training.

- When choosing a product, consider your capabilities: if you do not want to stir the concentrate yourself until you get a homogeneous solution, or you are afraid that you cannot guess the consistency, you should prefer the finished soil.

- Make a start on the type of surface and the concrete finish you are going to use: the primer for concrete and metal is different.

- Pay attention to the variety with anti-corrosion properties, if you intend to finish the metal facade.

- In rooms with high humidity will be appropriate variety that prevents the formation of fungus and mold.

Pay attention to the packaging. Usually the manufacturer indicates the characteristics of the particular material being produced. This will allow you to understand how suitable this primer is for the surface treatment of your house (apartment). If the type of raw material does not match the surface to be treated, re-repair is not excluded soon.

Tips and tricks

Any primer material should be used strictly in accordance with the technological instruction. This will improve the quality and practical characteristics of any facing materials.

Acrylic primer is applied strictly on a clean and prepared surface. In this case, the treated surface should be as fat free as possible, dry and smooth. It is worth paying attention to the shelf life: after it has passed, the material loses its qualities, therefore it will be meaningless to wait for a good adhesion from the primer.

Depending on the size of the area, they use a roller and a brush during processing. A brush is needed for corners and bottlenecks inaccessible to the roller.The roller allows you to significantly simplify and speed up the surface treatment, to make the distribution of the primer solution uniform.

If the solution is concentrated, it is necessary to prepare it strictly according to the instructions specified by the manufacturer on the package. It is possible to carry out processing at a temperature from +6 to 35 degrees. If you need to prime the surface outside, you can work at a temperature of +12 degrees.

Experts recommend treating the surface twice. In addition, each layer applied to the surface should dry well. The minimum allowable interval between two treatments is 4-5 hours (provided that it is hot in the room). Leftovers tightly closed and cleaned in a dark place. You can not keep them in the light. Storage temperature corresponds to the temperature during processing.

Manufacturers and reviews

A wide range of acrylic primers is presented on the modern construction market. Among the abundance of goods especially discussed materials are solutions of companies:

- "Norteks soil" - antiseptic deep-penetrating products for the preparation of water-dispersion paints and varnishes.

- Lacra - high-quality latex primer based on aqueous acrylic dispersion with anti-mold additives.

- Cerisit - solutions of deep penetration in the form of an aqueous dispersion of acrylic copolymers, supplemented with pigments and mineral additives.

- "Miners" - a universal primer for interior use, a finished product that does not require dilution, designed for highly absorbent surfaces.

- Vika - acrylic primer of two tones (gray and white), designed for surface treatment of metal and plastic, with anti-corrosion properties.

- Caparol - the universal remedy for the internal and external works intended for mineral types of surfaces.

- Knauf - a universal preparation for processing walls, floor and ceiling with adhesive properties and leveling the surface.

- "Styrene" - primer of deep penetration based on acrylic copolymers, designed for highly absorbent surfaces, including brick, concrete, plaster, cement.

- "Tex" - soil waterproofing for dedusting porous types of surfaces for putty, paint, wallpaper.

In general, reviews of these compositions are positive.The comments indicate a high consumption of domestic soil. Sometimes it takes much more to work on the floor and walls than is indicated by the manufacturer.

On the nuances of choosing a primer, see below.