Heat-resistant silicone sealant: pros and cons

Construction work can not be done without sealants. They are very widely used: to seal joints, remove cracks, protect various building elements from moisture penetration, fasten parts. However, there are situations when such work must be carried out on surfaces that will be subjected to very large heating. In such cases, heat-resistant sealants are needed.

Special features

The task of any sealant is to form a durable insulating layer, therefore many requirements are imposed on a substance. If you want to create insulation on highly heated elements, you will need a heat-resistant material. There are more requirements for it.

Heat-resistant sealant is made on the basis of polymeric material - silicone and is a plastic mass. During production, various substances can be added to the sealants, which give additional characteristics to the product.

Most often, the product is available in tubes, which can be of two types. Of some, the mass is simply squeezed out; for others, a mounting gun is needed.

In specialized stores you can see a two-component composition, which should be mixed before use. It has strict operational requirements: it is necessary to strictly observe the quantitative ratio and not allow accidental ingress of even drops of the components into each other in order to avoid an immediate reaction. Such compositions should be used by professional builders. If you want to do the work yourself, get ready one-component composition.

The heat-resistant sealant has a very wide range of applications in a variety of construction and repair works, due to its remarkable properties:

- silicone sealant can be used at temperatures up to +350 degrees C;

- has a high level of plasticity;

- fire-resistant and not subject to ignition, depending on the type can withstand heating up to +1500 degrees C;

- able to withstand a large load without losing its sealing properties;

- high resistance to ultraviolet radiation;

- can withstand not only high temperatures, nor frosts down to -50 - -60 degrees C;

- It has excellent adhesion when used with almost all building materials, while the main condition - the materials must be dry;

- moisture impermeability, immunity to acid and alkaline formations;

- long service life;

- it is safe for human health, since it does not release toxic substances into the environment;

- when working with it, the use of personal protective equipment is optional.

Silicone sealant has significant drawbacks.

- Silicone sealant should not be applied on wet surfaces, as this will reduce adhesion.

- Surfaces should be well cleaned of dust and small debris, as the quality of adhesion may suffer.

- Quite a long curing time - up to several days. Work at low temperatures in air with low humidity will increase this figure.

- It can not be painted - paint dries off after drying.

- They should not fill very deep gaps. When hardening, it uses moisture from the air, and with a large depth of the seam hardening may not occur.

Do not exceed the thickness and width of the applied layer, which must be indicated on the packaging. Ignoring this instruction may subsequently lead to cracking of the sealing coating.

It should be remembered that a sealant, like any substance, has a shelf life. With increasing storage time, the time required for curing after application increases. There are high requirements for heat-resistant sealants, and to be sure that the stated characteristics are in accordance with the quality of the product, purchase the product from reliable manufacturers: they will have a certificate of conformity.

Species

Sealants are widely used. But for each type of work you need to select the appropriate type of composition, taking into account its characteristics and the conditions for which it is used.

- Polyurethane suitable for many types of surface, perfectly seals.With its help, they build the building blocks, fill the seams in a variety of structures, make sound insulation. It withstands heavy loads and harmful environmental effects. The composition has excellent gluing ability, it can be painted after drying.

- Transparent polyurethane sealant is used not only in construction. It is also used in the jewelry industry, as it firmly holds metals and non-metals, suitable for creating subtle neat connections.

- Two-component professional The composition is complex for domestic use. In addition, although it is designed for different temperatures, it cannot withstand the long-term high-temperature mode.

- When installing and repairing structures that are exposed to high heat or fire, it is appropriate use of heat-resistant formulations. They, in turn, depending on the place of application and the substances contained, can be heat-resistant, heat-resistant and fire-resistant.

- Heat resistant silicone designed to seal those places that during operation warmed up to 350 degrees C.These can be brickwork and chimneys, elements of heating systems, pipelines supplying cold and hot water, joints in a ceramic coating on the heated floor, and external walls of stoves and fireplaces.

To sealant acquired heat-resistant quality, it is added iron oxide, which gives the composition a red color with a brown tint. When frozen, the color does not change. This feature is very useful when sealing gaps on a masonry of red brick - the composition on it will not be noticeable.

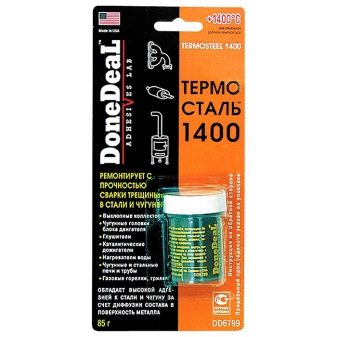

Option heat-resistant sealant exists for motorists. It is often black in color and is intended for the process of replacing gaskets in the car and other technical work.

In addition to resistance to high temperatures, it:

- does not spread when applied;

- resistant to moisture;

- oil and petrol resistant;

- tolerates vibrations well;

- durable.

Silicone compounds are divided into neutral and acidic. Neutral during solidification, it emits water and alcohol-containing liquid, which does not harm any materials. It is suitable for use on any surfaces without exception.

Acidic acid is released during acidification, which can cause metal corrosion.It should not be used to apply on concrete and cement surfaces, as the acid will react, salts will form. This phenomenon will lead to the destruction of the sealing layer.

When sealing compounds in the firebox, the combustion chamber, it is more appropriate to apply heat-resistant compositions. They provide a high level of adhesion of concrete and metal surfaces, brick and cement masonry, withstand temperatures of 1500 degrees C, while retaining the existing characteristics.

A type of heat resistant is fireproof sealant. It withstands the effects of open flame.

When building stoves and fireplaces, it is advisable to use a universal adhesive sealant. This heat-resistant composition can withstand temperatures above 1000 degrees C. In addition, it is refractory, that is, it can withstand an open flame for a long time. For structures in which the fire burns, this is a very significant feature. Glue will not allow the ingress of fire on surfaces with a melting point well below 1000 degrees C, and which emit toxic substances during melting.

Scope of application

Heat-resistant silicone sealants are used both in industry and in everyday life when performing work on the installation of individual structures. High-temperature compounds are used to seal the threaded connections in the pipelines of the hot and cold water supply and heating systems in buildings, since they do not change their properties even at high negative temperatures.

In various fields of technology, they are needed to glue metal and non-metallic surfaces., silicone rubber to seal the seams in contact with hot surfaces in furnaces, engines. And also with their help, equipment operating in air or in conditions where there is vibration is protected from penetration of moisture.

They are used in areas such as electronics, radio and electrical engineering, when you need to fill the elements or make electrical insulation. During car maintenance, heat-resistant sealant is treated from the formation of corrosion of a place whose working surface is very hot.

It often happens that the kitchen appliances fail under the influence of various factors.In this situation will help high-temperature food sealant. The product is necessary for gluing the fallen off glass of the oven, for repair and installation of the oven, hob.

This type of sealant is often used in food and beverage factories., at repair and installation of equipment in kitchens of institutions of public catering. Do not do without a heat-resistant composition in the elimination of cracks in the masonry stoves, fireplaces, chimneys, when sealing up welds in boilers.

Manufacturers

Since heat-resistant sealants are needed for structures that are operated under extreme conditions, the product must be purchased from reputable manufacturers.

You should be alerted by a too low price. The fact is that some manufacturers add cheap organic substances to it to reduce the cost of goods, reducing the proportion of silicone. This is reflected in the characteristics of the sealant. It loses its strength, becomes less elastic and resistant to high temperatures.

Today there are many manufacturers of high-quality goods on the market, they provide a wide choice.

Good consumer properties are distinguished by the “High-Temperature Moment Germent”. Its temperature range is from -65 to +210 degrees C, the non-durable period withstands +315 degrees C. It can be used to repair cars, engines, heating systems. It seals well, exposed to prolonged temperature effects. "Germent" is characterized by a high level of adhesion with various materials: metals, wood, plastic, concrete, bituminous surfaces, and insulating panels.

Motorists for repairing cars often choose ABRO sealants. They exist in a wide range that allows you to make a choice for cars of different brands. They are available in different colors, are able to create pads within a few seconds, take any form, have high strength and elasticity, and are resistant to deformation and vibration. They do not crack, oil and petrol resistant.

For a variety of works suitable universal silicone adhesive sealant RTV 118 q. This colorless one-component composition easily reaches hard-to-reach places, has self-leveling properties.It can be used with any materials and can also come into contact with food. The adhesive acts at temperatures from -60 to +260 degrees C, resistant to chemicals and climatic factors.

Estonian product Penoseal 1500 310 ml will be needed for sealing seams and cracks in structureswhere heat resistance is required: in stoves, fireplaces, chimneys, stoves. After drying, the sealant acquires high hardness, withstands heating to +1500 degrees C. The substance is suitable for surfaces made of metal, concrete, brick, natural stone.

In the next video you will find a review of heat-resistant sealant PENOSIL.