Features of the choice of silicone sanitary sealant

Reliable sealing of sanitary equipment is an important task, which determines the success and duration of its operation. It is especially important to carefully approach the docking of various non-standard parts. To ensure a strong connection will help specially designed for this silicone sanitary sealant.

Composition and types of silicone materials

Sealant for sanitary works is a thick, viscous mixture based on silicone polymers with the addition of fungicidal substances, designed to prevent the development of mold, fungus, reproduction of pathogenic bacteria.

The composition of sanitary means:

- silicone rubber;

- plasticizer made of silicone, giving plasticity to the material;

- fillers for extra volume and color;

- a vulcanizer that makes a mixture of rubber-like, elastic and viscous;

- an amplifier with thixotropic properties, strengthening the structure and not allowing the mixture to spread.

Vulcanizers determine the type of product:

- Neutral Sealants (amine, alcohol and amide). The compositions do not have a sharp smell. They can be used for any coatings.

- Acidic. They are composed of carboxylic acids, evaporation of which is toxic and dangerous to health. They can not be used for processing metal and marble surfaces, building materials containing cement.

Two-component mixtures mainly have a production scope, and one-component mixtures are widely demanded in everyday life.

Basic properties

Sanitary silicone has an optimal level of adhesion with the coating, prevents the damaging effects of ultraviolet rays, can be applied to surfaces with different temperatures.

The complex composition of the material determines its properties and technical characteristics, including:

- resistance to high humidity;

- Immunity to temperature fluctuations, with standard compositions, the limit of oscillations is from -50 to +200 degrees, heat-resistant ones withstand temperatures up to +300 degrees;

- silicone agents are not exposed to aggressive environment;

- Sealants are characterized by maximum elasticity and can stretch by 900%, so the joints are protected at any displacement.

The most popular blend for plumbing work is white moment sealant. It is easy to use, has a high resistance to chemical compositions and climatic conditions. In addition, it contains antiseptics and fungicidal additives.

The composition of Kiilto is ideal for working with plumbing and tile. It differs in heat resistance and water resistance, ensures complete match with the color of the putty.

You can also note the high quality tools Soudal. It is a neutral, water-resistant composition with good elasticity and a high content of antifungal components. Suitable for interconnecting different materials - metal, ceramics, polyester, glass.

These sealants are the most popular and safe for sealing in residential areas.

Purpose of sanitary mixes

Silicone sealing compounds are designed for rooms with high humidity, for processing sanitary devices, sealing joints between surfaces of different chemical composition.

Silicone sealant:

- protects equipment from temperature changes;

- maintains the working condition of connecting pipes and protects them from the damaging effects of various active substances contained in water;

- prevents leakage with strong liquid head;

- the composition is indispensable in the assembly of water supply for different threaded connections;

- it is used in the absence of sealing rings and for their hardening;

- used for auxiliary waterproofing during repairs.

The tool allows you to provide both internal and external protection of compounds. Especially it is important for buildings made of polyvinyl chloride. With the help of such a liquid and viscous composition, the sewers of the sewage pipes, which are placed in the socket, are treated, rubber cuffs are hardened, which cannot guarantee optimal tightness. In this way, the required structural strength is achieved, and its service life increases.

In addition to the processing of pipes, with the help of sanitary silicone it is possible to carry out finishing work and seal joints of tiles in rooms with high humidity.

Release form

Convenience is represented by a sealant package, it is produced in a tube from 100 to 310 ml and is equipped with a piston engine, due to which it is easy to charge a mounting gun for polyurethane foam. It is comfortable to work with such a tool and you can adjust the amount of sealant. If a mixture remains in it, it is necessary to tightly plug the hole.

If you need a large amount of money, you can buy soft packaging weighing 600 ml, but for work it is necessary to use a construction tool of a different type.

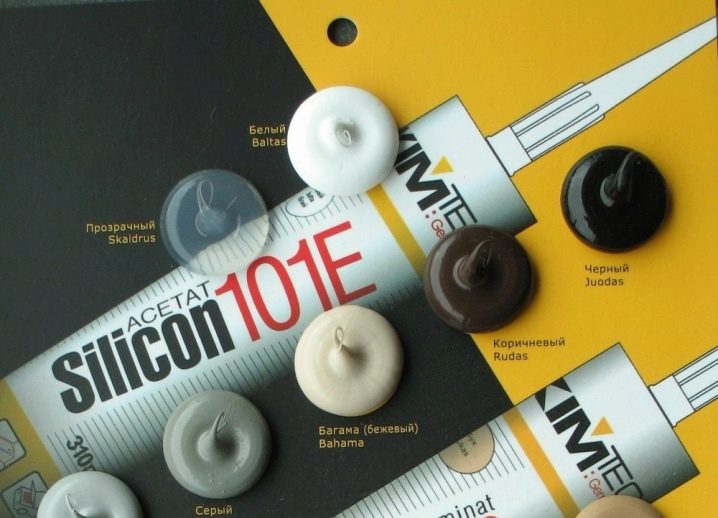

When buying, you should pay attention to the conditions of use indicated on the package. For different surfaces, you can choose different colors of the encapsulating material, for example, white, yellow, pink, black, and colorless.

Terms of use

Proper use eliminates the loss of elasticity sealant and the appearance of cracks. Therefore, it is necessary to carry out work consistently.

- For optimum adhesion, surfaces should be cleaned if they have dust, dirt and rust.

- After that, a cartridge with a mixture is inserted into the construction gun and the joints are processed. It is desirable that the applied line is not interrupted.

- Surplus substances that are not intended for this purpose are immediately wiped with a napkin.

- After 5 minutes after application, begin to make a seam. Form it moistened with a spatula or gloved hands.

- If the agent is still left in unwanted places, remove the excess mechanically or with the use of a solvent.

- The composition dries out completely after about 15-20 minutes, after which it is impossible to make corrections.

Selection features

If you are going to buy a tool for sealing equipment in the bathroom or bathroom, should take into account some of the nuances.

- Silicone adhesive sealants are suitable for metal products: aluminum, copper, mercury hard alloys. But they can glue together any combination of materials. At the same time there is no need for preliminary preparation of surfaces because of good adhesion.

- Acid sealants are more suitable for the treatment of water supply pipes, since they are not subjected to biocorrosion. It is better not to use them for non-ferrous metals due to the destructive impact.In addition, acidic products contain biocides, so such compounds should not come into contact with the places of placement of products.

- Neutral silicone mixtures are needed when working with plastic parts of equipment, but they are difficult to paint. That is why you should immediately choose a specific color to mask the joints.

- White or transparent water-resistant composition is usually used to seal water structures, which ensures a reliable connection of sanitary devices, shower cubicle panels, gaps between the wall and the bathroom, and fixing a toilet bowl. It also helps avoid stains and mold.

- It is better to purchase sealants that have additional characteristics, such as heat resistance, fire resistance and other qualities.

It is important to pay attention to such issues as drying time. This and other information is usually contained in the instructions or indicated on the package. Sealant must be selected for its intended purpose and suitable for operating conditions.

It is always necessary to check the shelf life of products, as well as the integrity of the packaging material, as this may affect the quality of the sealant.In addition, it is wiser to purchase such a product from a trusted manufacturer.

To plumbing equipment served for a long time, it is necessary to effectively seal the plumbing fixtures. To do this, select the appropriate quality tool and apply it correctly. This will be the key to success.

On the intricacies of applying silicone sealant to seal the seams in the bathroom, see below.