Types of sealants for wood

It has been built from wood for many thousands of years, and this natural material is deservedly popular with builders for its excellent qualities. However, there are difficult moments in working with wood. It has a rather large coefficient of expansion and compression with temperature and humidity variations. In this case, they say that the tree "breathes." For the home, such breathing is fraught with cracks between wooden parts and cracks. During operation, the owners constantly close up these gaps in various ways.

Previously, the gaps and mezhventsovye seams caulk tow, flax, jute, moss, and other improvised materials. These natural seals had a number of drawbacks, for example, they absorbed water, let in heat, and served not for long.With the development of building technologies, innovative materials have emerged that are able to solve the problem of sealing joints and cracks in wooden structures - sealants for wood.

Special features

In stone houses there are a lot of wooden parts and assemblies that are subject to drying and deformation, for example, the rafter system, logs, doorways, therefore sealants are used in all types of buildings. The purpose of the sealant is to isolate the cracks and cracks from moisture penetration and heat loss.

This material contains many components.which give it the necessary properties: binders, plasticizers, antiseptics, dyes, polymers. The consistency sealants are pasty, similar to thick glue. Regardless of the type of sealing compounds for wood have the following advantages:

- plasticity - the ability to fill all voids, joints, penetrate into the depth of cracks;

- elasticity - the ability to withstand the load when drying wooden parts without deformation;

- adhesion - strong coupling with wood;

- resistance to temperature fluctuations without changing working qualities, frost resistance;

- moisture resistance to ensure the waterproofing of joints and seams;

- antiseptic properties that prevent the development of rot, bacteria, harmful microflora, insects;

- long service life;

- low thermal conductivity to maintain heat in the house;

- invisibility, which is important for the repair of decorative wooden surfaces.

For ease of application, manufacturers have packed sealing paste in a special building syringe with a thin nose. The composition includes colourants that imitate the shades of various wood species, which allows you to make the seams invisible. When the solvent evaporates, the process of polymerization occurs and the sealant hardens, acquiring the calculated strength.

Kinds

There are several types of sealants for wood, they are divided by scope and are for internal or external use. Universal pastes of wide application are produced, there are also mixtures especially for windows, roofs, log cabins. For special properties, you can distinguish waterproofing, thermal insulation and sanitary seals. The composition can also be divided into several main groups.

Acrylic Sealant Based on acrylic resins, it has high strength properties and is resistant to temperature extremes. It is used to seal joints in the floor, walls, ceilings, partitions, sealing windows and doors. The composition has excellent moisture resistance, which allows for wet cleaning of surfaces, is also non-waterproof. Differs in environmental friendliness and fire safety, is available at the price.

Acrylic sealer can be tinted in any color, covered with paint or varnish on top, thanks to this, the color of the floor and walls will have a smooth tone without stripes and spots. The disadvantage of this material is low elasticity and susceptibility to deformation when exposed to significant loads.

For outdoor work acrylic composition is not suitable.

Silicone sealant not afraid of ultraviolet radiation, frost and surface heating, it works at temperatures from -50 to +140 degrees. It withstands deformation loads and compensates them perfectly, does not let moisture and heat through. This material is universal, used for both internal and external works. Silicone suture seals have the longest service life - up to 40 years.Due to its high elasticity and resistance to changing conditions, this material is used as an inter-seal seal.

Silicone sealant of various colors is produced, but it is impossible to apply a paint and varnish covering on it. A repeated layer or a point correction additive after solidification will not stick to the first layer. Therefore, the silicone composition is applied once.

There are three types of compounds.

- Acidic acids have increased strength and have a sharp acidic odor, which disappears as the material dries and polymerizes;

- neutral compounds are more environmentally friendly, but less resistant to weathering;

- sanitary sealants contain special antiseptic additives that prevent fungal and mold damage to wood.

Bituminous sealant is made on the basis of bitumen and rubber. Its waterproofing properties make it possible to use this material for sealing and repairing roofs, drains, and places with high humidity.

It happens only in black, not painted.

Polyurethane composition quickly hardens and has excellent weather resistance,excellent sealing properties and adhesion. Frozen seam can be painted. It has excellent adhesion even when applied to a wet base. Polyurethane sealant is waterproof, designed to work in conditions of high humidity and sealing for dry and hard surfaces. They produce such seals with different indicators of hardness.

The disadvantages include the presence of a pungent odor, because of which it is possible to use the polyurethane composition only on the street.

Color palette

The hue of the sealant is important, especially when repairing wooden coatings, when you want the place of repair to be imperceptible. In this case, selects the color that is closest to the main. It should be noted that the seal acquires the final color only after complete solidification. Manufacturers have developed colors that imitate different tree species, such as wenge, larch, pine, oak, rosewood, teak, walnut.

For decorative gazebos, baths, orphanages and other wooden structures, the original solution would be to use contrasting shades of sealant. Colored seams will give the building a spectacular and elegant look.You can choose a neutral shade, then the seams will be visible, but not much. If the line of finished products did not find the desired color, then you can order almost any color.

Silicone sealants can not be painted, the bitumen composition is only black, and other types can be coated on top with varnish or paint of the desired tone.

Manufacturers

Even in stone houses there are wooden joints, so here too it is necessary to use sealants for wood. Therefore, such compositions are familiar to every zealous owner of a private home. The construction market is saturated with products for the repair and sealing of wooden parts of the house. On the shelves there are both imported and domestic manufacturers of sealants.

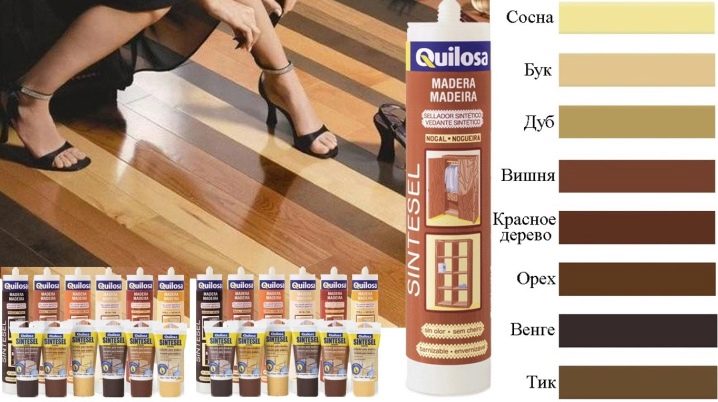

Spanish company Quilosa It has been operating in the European market for more than 70 years and during this time it has developed and produced more than 500 items of high-quality sealants, adhesives and polyurethane foams for use in various fields of construction. This manufacturer has large factories around the world - in Korea, Turkey, China, Brazil, Poland.

The products of this company have the following competitive advantages:

- product quality has been tested by many years of use in various regions of the world;

- produces special products for the northern regions;

- there are separate products for professionals and for domestic use;

- a wide range of kits and product systems that are perfectly compatible with each other;

- these are heat-resistant innovative products;

- rich color palette.

Excellent feedback is given to wood sealant that any ordinary person without building skills can use at home. It is called Quilosa Sintesel Wood Madera. This siliconized material has excellent adhesion to most basic materials. Suture seal is used to repair flooring, baseboards. They are sealing mezhventsovyh seams in wooden log cabins. Products do not darken over time and absolutely odorless.

The hit of Russian sales is deservedly a universal acrylic sealant for woodworking. "Accent". It is produced completely ready for use and can be used inside and outside, as well as under adverse operating conditions.It is universal and engages not only with wood, but also with concrete, metal, and brick.

It has a unique elasticity and is adapted to Russian weather conditions, resistant to ultraviolet radiation and durable.

After applying the sealant begins to dry and forms an elastic material, similar in properties to rubber, which can only be removed by mechanical means. Product durability "Accent" is 25 years old. Frost-resistant and heat-resistant sealant is not recommended to be applied during snow and rain. Buyers mark the perfect combination of an affordable price and high quality of this product.

Active and confident participant in the market of paintwork materials and construction chemicals - Russian company Rogneda. For 20 years of rapid development, this manufacturer has established itself as a reliable and stable supplier of quality products designed for our climate.

In the most modern laboratories and on test sites, products undergo numerous tests, phased quality control, new developments. Among the brands produced by this company, it is worth highlighting the well-known brand. Eurotex, in the assortment of which an undeniable hit is acrylic seam sealant for wood.

- Sealing of window and door openings, floors. It is plastic, gives a beautiful smooth seam, can be applied both with the assembly gun, and the spatula.

- Compaction of intervents seams and cracks in the timber, does not exfoliate due to natural shrinkage of the wooden house. The material prevents the further development of cracks, is durable and elastic.

- Repair and repair of damage in wooden structures. The compactor prevents the development of mold, is environmentally safe, does not emit sharp odors. It is made in various colors, imitating wood and tinted with special pastes in any shade at the request of customers.

The use of this sealant is possible inside and outside the premises, in conditions of high humidity, including baths, saunas (except steam rooms). Sealant applied Eurotex for work with all materials based on wood: plywood, chipboard, fiberboard. The durability of the material is 30 years when working inside buildings and 20 years when used outside under more severe conditions.

Famous German mark Ramsauer It began work 135 years ago and during this time has gained invaluable experience in the production of protective materials, putties and adhesives.Today, this company produces absolutely all types of sealants, including premium products.

Unicomponent acrylic inter seam sealant Ramsauer 160-Acryl perfectly maintains various loadings and shrinkage of wooden joints and seams. They are treated with joints of wooden parts with stone or brickwork, plaster, concrete. It dries very quickly and forms an elastic coating with high levels of thermal insulation, the so-called “warm” seam.

Sealant Acryl-160 universal and suitable for outdoor and indoor use. Full hardening occurs after 1-2 weeks, depending on the conditions of temperature and humidity. It can be applied manually and using a pneumatic construction gun.

This seal is frost resistant and can withstand negative temperatures down to -45 degrees.

How to choose?

Such a huge range puts the buyer before choosing the best option for a particular wooden house or apartment. Today, both universal pastes, the scope of which is quite wide, are being produced, as well as special materials for processing specific components and solving narrower technical problems.

To begin with, it is necessary to determine several factors on which the choice of a particular variety depends:

- materials whose joints need to be sealed;

- types of work, such as sealing seams or cracks, joints of parts;

- tasks that need to be solved with the help of a compactor: insulation, prevention of rotting, waterproofing;

- special or difficult operating conditions, climatic region of use.

For mezhventsovyh seams log cabin is the most suitable acrylic sealant "Warm seam" or with the addition of latex and cellulose. It is applied once and withstands all loads and weather difficulties, shrinkage of the structure, protects from moisture and blowing, relieves from drafts and heat losses.

The bituminous sealant perfectly is suitable for works on a roof.

It forms a coating similar in properties to rubber and perfectly waterproofs joints and cracks in the wooden parts of the roof.

For internal work on sealing the gaps of the parquet, the floor boards are often used universal acrylic sealant, which can be painted and washed from the top with detergents, which allows you to do wet floor cleaning, and make the joints invisible.

Silicone or polyurethane sealant is recommended outside for the treatment of wooden bath elements outside, and acrylic inside. When buying, you should carefully review the information on the package, instructions for applying, make sure that the certificates and guarantees of the manufacturer are available.

How to use?

The technology of applying sealants for wood is simple and affordable. Anyone without special skills can do all the work with their own hands. It is better to work in dry, warm weather, then after polymerization the seams will acquire all the necessary properties.

New log house is enough to clean the dust, wiping with a clean cloth. If the surface is impregnated with oil impregnation or has been used for a long time, then it is recommended to remove the top layer of wood with a grinder or ordinary sandpaper in a jet-abrasive manner. Logs and areas affected by fungus or mold are treated with antiseptic and fungicidal compounds, otherwise the rotting of the tree will continue and face complete destruction.

Wide gaps and mezhventsovy gaps lay foamed polyethylene.This material has replaced the sealing cord from natural materials and perfectly warms the gaps, does not absorb moisture, saves sealant consumption.

A tube with a sealing compound is filled into a gun and the spout is cut at an angle of about 45 degrees and with a diameter of 4-5 mm. If the composition is packed in buckets, then pick up the gun, holding it vertically. Extrude sealant into the interstitial gap, carefully filling voids and cracks. Then with a spatula level and smooth down the seam.

You can apply the paste and spatula with a rounded spout to create a smooth and beautiful seams.

Excess sealant must be removed before setting, or pre-glue the necessary areas with masking tape. You can trim the seams with a spatula or clean it with a cloth. Thus, vertical joints should be processed.

To seal cracks, you must first clean them from debris, dirt and dust. To do this, it is best to use a knife or a narrow screwdriver, compressed air for purging. Then both edges of the crack are sealed with masking tape, and a sealing cord is laid in depth. Then fill the gap with a sealant and level the surface of the seam with a wet spatula.The final shade composition will dial in a few days after complete solidification.

Painting will make the place of repair invisible.

Tips

A stone, brick or chopped house has many wooden parts and needs special protection with wood sealants. So that the money spent and efforts are not wasted and the seams serve as long as possible, It is necessary to follow the recommendations of experienced builders and manufacturers on the correct use of sealants on wood:

- shrinkage and deformations are still occurring in new log cabins, the cork floor has the same characteristics, therefore more flexible compositions should be chosen;

- when buying, check the expiration date of the mixture indicated on the package

- structures made of glued timber shrink less and become less deformed, which means that the sealant is suitable for them and is universal and inexpensive;

- work can be done in the cold, but it is better to choose warm and dry weather.

How to insulate a wooden house by means of sealant, you can learn from the video below.