Acrylic Sealant: Pros and Cons

In the process of carrying out finishing works, there is a need to handle connecting joints. Today, in the building materials market, acrylic sealant is in great demand because it can be used to protect objects from the negative effects of moisture and temperature changes. But before you purchase this product, you need to familiarize yourself with its advantages and disadvantages.

Special features

Acrylic compounds are used to connect fixed or inactive parts. Acrylic sealant can be water resistant. Such a composition is easily diluted with water and is characterized by an environmentally friendly composition. It can not be used, equipping rooms with high humidity. The material does not withstand strong deformations and low temperatures.

Masters use this composition when working with plasterboard or brick surfaces, as well as for redecorating furniture and installing baseboards.

Acrylic composition is resistant to moisture. It is used in working with wet rooms - bath, swimming pool and sauna. The composition can not be diluted with water and the substance is used immediately after opening the package.

The basis of acrylic glue is durable plastic. Characteristics of the material depend on its components. The liquid that makes up the material evaporates over time. Within a day, the water disappears completely and the sealant freezes. In addition to plastic, the sealant contains thickeners and additives.

Among the advantages of this material can be identified ease of use. Acrylic material can be diluted with water, so it can be easily removed from the surface. Also, the sealant can be diluted to obtain a comfortable consistency. After hardening, it is easy to remove from the surface with a knife. Acrylic sealant is universal, has a relatively low price and a large selection of varieties.

The water base is safe, so you can use sealant without additional protection.The material is non-toxic and does not cause allergies. The material contains no flammable substances, which increases the resistance of the material to elevated temperatures. Due to the adhesive properties, the sealant can be used on virtually any surface. The material is suitable for both glossy and rough grounds.

Acrylic sealant is capable of passing steam: water between the seams of the tile does not accumulate. This property helps protect the surface from rotting and fungus formation. Over time, the bright composition will not turn yellow. Under the influence of ultraviolet rays the surface does not crumble. Silicone foam, also used in construction for the treatment of joints, does not possess such resistance.

Sealant can be additionally coated. Acrylic does not collapse when in contact with the ink base; therefore, it is considered a versatile material. Ready joint can be restored. The sealant is easily removed from the surface and is easily applied in several layers.

Properties

The scope of application of the sealant is quite large. With the help of an acrylic composition, you can restore the wooden parquet, to process the laminate.Masters use sealant when installing windows and doors. Without it, it will be very difficult to seal the lines connecting the pipes, seal the baseboards and seams between fragments of ceramic tiles.

Sealant can be used as an adhesive when repairing furniture.

The main property of acrylic sealant is elasticity. Plasticizers included in the composition, give it an elastic consistency. The material withstands continuous vibration without damage. The tool is suitable for sealing narrow joints and spreading cracks, because it can penetrate small holes and seal them. To obtain the desired result, the material is simply poured onto the surface.

The main distinguishing features of the material - the ultimate elongation at critical load and wear resistance. After drying, the material may shrink slightly. For a good material, the displacement amplitude will not exceed ten percent of the maximum elongation. The more irreversible deformation, the less quality material was selected. If the tension of the sealant exceeds the limit value, the material will not be able to assume its original position.

Masters are not advised to choose an acrylic mixture for working outdoors. Sealant for exterior applications should have increased frost resistance, since the material will have to withstand several freezing cycles. Such a composition is usually characterized by increased rigidity. The optimum temperature of drying of the composition - the interval from -20 to +70 degrees.

Masters recommend applying a sealant with a layer width of 5-6 millimeters and a thickness of not more than 0.5 mm from the width. If the distance between the panels exceeds six millimeters, then experts advise against increasing the sealant layer. Instead, a sealing cord is used. Its diameter varies from 6 to 50 mm. It is designed to connect the panels during installation and protect the joint from moisture.

The hardening time of the coating depends on the density of application. With a sealant thickness of 10-12 millimeters, the curing time reaches 30 days. The material hardens while maintaining constant humidity and temperature. It is not necessary to constantly air the room. Enough to maintain 20-25 degrees, and humidity from 50 to 60 percent. Subject to all rules, the sealant may harden for 21 days.

The setting time of acrylic sealant is one hour. But to remove the coating from the surface is not difficult. Paint sealant is possible only after complete drying. You can store unpacked material for about six months in a room with an air temperature of +20 degrees.

The main disadvantage of the adhesive composition is low moisture resistance.

It is forbidden to apply the composition to the surface, which constantly interacts with moisture. If it is necessary to apply the composition during rain, it is necessary to protect the outer layer with a sheet of polyethylene. Prolonged contact with water causes depressurization and flaking of the coating.

When buying a sealant it is necessary to consider its scope. For each type of work should be selected individual composition. Universal material can be used everywhere when working indoors. But for the decoration of the facade of the building it will not work.

Species

Depending on the behavior after application to the surface, the material is divided into three types: drying, non-hardening and hardening. The first group includes compositions based on polymers.This sealant freezes after a day without additional manipulations. The drying acrylic blend can be two-component and one-component. Before applying the sealant with a complex composition must be thoroughly mixed. Single component material does not need mixing.

Non-hardening sealant produced in the form of mastic. The elastic mass must be kept at a temperature of 20 degrees for at least a day. The material is resistant to heating up to + 70 ° C and cooling to -50 ° C. The width of the junction of the panels can vary from 10 to 30 mm. This sealant is mainly used in the design of facades of buildings, even in regions with a harsh climate. The hardening composition is based on silicone materials. The components of the sealant freeze in the course of the chemical process (vulcanization).

In appearance, the compositions are colored, transparent and white. The color of the sealant remains almost unchanged after drying. Transparent silicone in the composition may slightly dim, the intensity of acrylic will not change. Some types of sealant are transparent, but with the addition of coloring pigment. This composition is used when working with glass products.The sealant has light transmittance and adapts well to the transparent material.

Siliconized colorless sealant is widely used when installing plumbing fixtures. This composition is waterproof, therefore, suitable for interior work in the bathroom. The composition protects the surface from leaks and mold. Due to the absence of color, you can get a coating without visible seams.

Masters use this material when installing kitchen furniture and glass shelving.

A colored sealant is purchased if the selected surface cannot be painted. To avoid an obvious color drop and preserve the integrity of the composition, experts advise to give preference to this type of material. Pigmented adhesive composition in its physical properties is not inferior to the colorless. The color palette of the sealant is wide enough. It is possible to get both gray, and black or brown material.

White sealant is good for painting. It is used for installation of plastic windows and light doors. The presence of pigment helps to determine the thickness of the adhesive composition and the uniformity of application.It is much easier to eliminate shortcomings, if the composition is visible on the surface. After complete drying, such a sealant is painted with the surface.

There are several types of product, depending on the area of use and the conditions of future operation.

- Composition based on bitumen. This type of sealant is used for external work - the elimination of cracks in the foundation and tiles. The material is able to fix almost any material due to the peculiarities of the composition. The sealant is resistant to heating and cooling to critical temperatures, and also does not collapse under the influence of moisture. The indisputable advantage of the material is the creation of strong adhesion.

- Universal sealant does not require special skills when applied and is suitable for almost all interior work. The material is frost-resistant, so it is often used when installing windows. Sealant tightly fills the gap, preventing the appearance of drafts. When working with wood masters recommend to use a colorless composition.

- Silicone sealant for aquariums. This material must not contain toxic substances. The adhesive is water resistant because it will be in constant contact with water after curing.High plasticity and adhesion allow to use this sealant when installing shower enclosures. Also suitable for processing ceramic and glass surfaces.

- Sanitary. This professional material is used to work in wet areas. The composition contains special anti-fungal components. The material protects the surface from the development of bacteria.

- Heat resistant. This fire-fighting composition is used in the assembly of furnaces, processing of joints of heating pipes and chimneys. The adhesive can withstand temperatures of up to +300 degrees, while retaining its physical and mechanical properties.

Such a tool can not be replaced when working with electronics and wires.

Application area

The seam can be treated with a waterproof and non-waterproof composition. Masters advise applying an acrylic adhesive to work inside the building. For the treatment of the facade of the building masters recommend using cold-resistant sealant. It is also suitable for interior work. It is impossible to work as moisture resistant sealant in the conditions of the increased humidity. It is usually used for the installation of wooden and plastic panels, polystyrene foam and drywall.

Acrylic is good at work with decorative elements. - ceramic fragments can be securely fastened to the concrete and brick wall. Installation can be carried out on walls with increased roughness. The sealant reliably clogs the seams of tiles and clinker panels. With the help of such adhesive composition, you can beautifully decorate the facade of the building, protecting the walls from the negative effects of the environment.

Waterproof acrylic sealant is used much more often. It is needed in work with various types of wood, ceramics, concrete and PVC panels. Thanks to the plasticizer in the composition, the adhesive composition is suitable for surfaces with varying degrees of roughness. The structure reliably fixes both porous and smooth surfaces. Waterproof material is recommended to use in the bathroom or in the design of the kitchen. It is well suited for working in wet areas.

Acrylic sealant is used to treat joints in wooden flooring. The adhesive composition is available in all shades. This allows the client to purchase material that does not differ in color from wood. Sealant has good adhesion to wood,therefore, it is often used to seal joints between bars. Material can be used at installation of a bath or giving.

The sealant is distinguished by its environmental properties.therefore it is used almost everywhere. The material allows to eliminate drafts in the room. In the composition of the sealant there are no components that emit harmful substances under the action of temperature, so this adhesive can be used in living rooms. In combination with panels of natural materials, sealant is often used to finish the bedroom and nursery.

Using the sealant brown shades create the final finish of the premises of wood. It is suitable for sealing holes from knot fallout. The scarred surface of the wood can be smoothed with a sealant of the appropriate color. Acrylic also helps to strengthen the wooden surface and protect it from delamination.

During operation, gaps can be formed between the panels, which must be filled with sealant.

Adhesive is required for fixing ceramic panels. This material is versatile and easy to use, so it will be easy to use even for beginners.Special adhesives require adherence to individual technology. Seizure of acrylic sealant does not occur immediately, which allows you to make the necessary adjustments at the initial stage of work. When working with tiles often use white sealant. The tile with white seams looks aesthetically pleasing, also this color serves as an ideal base for painting.

Sealant can be used when fixing the sill to a concrete base. A durable compound protects joints between concrete slabs. In external works, the adhesive composition is often used to seal cracks on stone surfaces. The coating protects the concrete from the penetration of water into the chips and the formation of a grid of surface cracks. Sealant also fights moisture.

Acrylic material is used to fix the ceiling cover. If necessary, fixing stucco or plinth can not do without the use of sealant. The composition provides reliable adhesion of panels to the surface and prevents the development of mold.

Consumption

To calculate the exact amount of sealant required for operation, you need to know the dimensions of the joint to be filled.The depth of the seam is multiplied by the width of the future strip and the flow value is obtained. Consumption is taken on one meter and is expressed in grams. If the seam is planned to have a triangular shape, then the flow value can be divided into two. This case is suitable for processing the connection of perpendicular surfaces.

To seal cracks it is necessary to take a sealant with a margin, since the exact dimensions of the gap is almost impossible to learn. For processing a 10 meter long seam, you need to spend 250 grams of silicone. Sealant produced in tubes of 300 grams - this amount is enough to handle this surface. Color sealer is better to buy the same brand and one batch, as the shade of the product may vary.

The use of sealant does not require additional equipment and possession of special skills. The material does not have a sharp smell and does not irritate the skin. Work can be performed without special protection of the respiratory tract and skin. The composition can be easily washed off with warm water from hands or tools.

Uncured composition is easy to remove.

When treating surfaces with sealant, some rules should be followed. Do not change the humidity and temperature in the room until the composition is completely dry.Do not use water in the bathroom or in the kitchen unless the sealant surface has hardened. Otherwise, the risk of smearing the adhesive is great.

The process of hardening the sealant is conventionally divided into two stages. First, the surface is tightened with a strong film. This stage lasts no more than three hours and allows for adjustments. Then the sealant seizes completely, but this stage lasts several days. With the onset of the second stage of the wizard does not recommend to affect the layer of material. Intervention can affect the structure of the frozen composition and reduce its physical and mechanical properties.

The sealant is applied with a special gun or spatula. Most often, the finished substance is sold in a special dispenser. After opening the package means is recommended to use until the end. Sealant can not be stored after the first application - it loses its basic properties. For large volumes of work, the masters advise buying sealant in buckets, as the use of a tube in large areas is problematic.

Before applying the adhesive composition, it is necessary to carefully prepare the rough surface.From seams remove dust, dirt and the remains of material. The space on which the sealant will be applied must be degreased. When you skip this stage, there is a risk of violation of the properties of acrylic. The required adhesion will be carried out only on a pre-treated dry surface.

Reduce material consumption and save money by using a sealing cord. Experts use this method when installing windows, baseboards, laying large ceramic fragments. The cord can reduce the consumption of adhesive by 70-80 percent, as well as increase the pace of construction work. The cord also serves as an insulator and prevents heat leakage.

How to wash off?

Often after using a sealant, its particles remain on a clean surface. These traces need to be removed. Among the methods of cleaning the coating from the frozen sealant is the removal of mechanical and chemical removal. Both methods do not require special skills and are available to everyone. They are used by both professionals of the business, and the beginning masters.

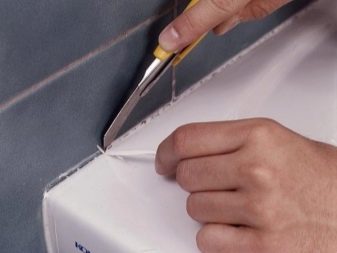

To clean the surface mechanically, you need a blade - a razor or stationery knife will do.

Excess glue is cut off with gentle movements. Remove sealant should be neatly, in layers. Small residues are rubbed with pumice stone or metal wool. Care must be taken to ensure that cracks do not form on the surface. For more delicate work, you can use a wooden scraper.

After completion of the work, the surface should be washed with a cleaning powder dissolved in water. The coating can be rubbed with a soft brush and left to dry completely. Hardened glue is contraindicated to tear off his hands. This may adversely affect the flawlessness of the coating. Monitor the quality of work at each stage - scratches can not be fixed.

When the plastic surface is contaminated with a plastic surface, the areas are cleaned with a plastic spatula. The use of metal cleaning devices on the plastic surface is prohibited. PVC is most sensitive to the effects of sharp objects. After processing the coating with a spatula, wipe the areas with a cloth.

Metal scourer and scouring powder are used only on surfaces that are resistant to a small external load. Wipe the cover should be a light circular motion with a little pressure.Such work requires patience and accuracy. But the result will justify the expenditure of time and effort.

The chemical method of removing sealant is to use a special solvent. Chemical cleaners are produced in the form of a pasty mass and aerosol. After applying the agent to the glue, its surface becomes plastic. Soft substance is easy to remove with a napkin or wooden spatula.

It must be tested before using the cleaner. Due to the large amount of aggressive chemical additives, the solvent can spoil the surface. To avoid loss of color or partial dissolution of the coating, the composition is applied to a small area and wait for some time. If the test is successful, then proceed to the treatment of the entire surface.

Need to work in a protective mask and special gloves. Substance is applied and waited for an hour. But before work it is important to familiarize yourself with the instructions on the solvent packaging - a different composition requires a different amount of time. The solvent is not recommended to be applied on the painted surface.

Fresh acrylic sealant is easily cleaned if wiped with a napkin napkin,vinegar or acetone.

When working with chemicals, it is necessary to ventilate the room well. The composition of the solvent can be very toxic, so do not neglect the safety rules. In the process of work it is not recommended to remove the protective mask - the chemistry may irritate the mucous membranes. Touching the composition with bare hands is also prohibited. Work with sharp blades should also be careful.

To protect the surface from contamination with a sealant, it must be sealed with masking tape. Adhesive tape is glued along the seam, protecting it from excess adhesive. It is better not to neglect such protection, because it is not always possible to carefully remove the sealant.

Manufacturers and reviews

Today in the market of building materials you can buy sealant from reputable manufacturers. Buyers note the quality of the composition from Germany, Poland and Russia. Masters do not recommend using materials of unknown brands - they do not exclude the use of low-quality raw materials. To avoid buying bad stuff you need to listen to the feedback from real buyers.

Customers note the affordable price of wood acrylic sealant "Accent". This brand produces five types of sealants. "Accent 136" easy to use even for beginners. About 40 kilograms of product is spent on 40 square meters of wall space. Buyers say good insulating properties of the material - the heat loss in the room has decreased significantly. Sound insulation increased, and insects from the apartment disappeared completely.

Sealant "Accent 117" pleases buyers waterproof. It is suitable for interpanel seams. Customers are pleased with the quality of products when comparing sealant with counterparts from other companies. The hardening adhesive is suitable for installing windows and interior doors. The coating has good adhesion.

"Accent 128" characterized by high content of silicone. Buyers recommend using this sealant to seal joints with slight deformation. The advantage of the composition is resistance to staining. Customers note that the coating can withstand several cycles of freezing. The apartment remains warm at low temperatures.

Acrylic Sealant "Accent 124" is multifunctional. Buyers advise to use it when performing outdoor work, as it is characterized by high adhesion to concrete. The composition is used to fill the cracks in the stone, brickwork and tile.

The material can be used to repair almost any surface - PVC, plaster or metal.

Another equally well-known firm - "Germent"pleases buyers with reliable fixation. Mechanical properties fully justify the price of the material. The structure reliably fixes the panels and is suitable for almost any surface. Among the disadvantages of buyers can note a sharp smell. Masters advise to work with this composition in a protective mask and in a ventilated room.

Brand Sealants Illbruck differ a large palette of shades. Buyers note the richness of the pigment and the preservation of color during operation. Material is suitable for work in areas of high humidity. Customers often use this compound when installing glass surfaces. Sealant also works with metal and concrete.

Hardening material Ramsauer 160 lays down evenly. Buyers are satisfied with the lack of smell. On this sealant the paint well lays down. Customers use the composition in special packages, providing the coating in an even layer. Sealant suitable for working with wood.

Tips and tricks

Sealant is chosen based on the type of material that will be fixed. Plastic, wood and metal have different properties and operating features. To increase the adhesion masters advise to additionally purchase a primer composition. A layer of this composition is applied to the rough surface before using the sealant. Intermediate primer increases the adhesion of the adhesive to the material, the connection becomes more reliable and durable.

When using a sealant in an aggressive environment, preference should be given to samples with the presence of fungicides in the composition. Such a sealant resists high humidity and is resistant to temperature extremes. Experts use it for arranging a bathroom or a balcony. The material may be toxic, so its use in the decoration of the kitchen is unacceptable. When in contact with food composition may adversely affect the health of the tenants.

For mounting the aquarium should pay attention to the composition of the sealant. The material must be water resistant. However, toxic substances in the composition should not be - sealant must be safe for animals. This material has an increased resistance to rupture.It can not be dissolved in water. Modern acrylic compounds can meet all the requirements of customers, but the choice of composition should be taken seriously.

For the treatment of cracks in the stove or chimney coating, preference is given to a sealant with a high heating temperature.

Permissible operating heating of such a composition should reach +300 degrees. Otherwise, there is a high risk of ignition of the material. Under the influence of critical temperatures, a simple acrylic sealant quickly loses its elasticity and collapses. In the shops you can find compositions that retain their properties when heated to +1500 degrees.

An important criterion for the choice of material is fire resistance. For work in warm rooms, it is necessary to choose a fire protection composition. Very often, additional protection is required for wood panels. The site of the log house and the joints of the bars must be processed and protected. When assembling baths or heated floors on logs with a wooden topcoat, all joints are coated with sealant to protect the structure from overheating.

Do not apply sealant in direct sunlight. Light accelerates the formation of a dry film on the surface of the coating and the curing process.The coating freezes unevenly, so the sealant can become covered with bubbles and cracks. The working surface must be closed with a screen. Pritaty wall must be within the first five days.

When buying a material, you need to ask for a certificate of quality. For each room there are prescribed rules and regulations. The documents indicate the requirements for materials and construction in each room. Sealant should be selected based on these data. The purchase of material is best carried out under the guidance of the master. In the modern market it is easy to purchase material of inappropriate quality.

For information on how to use acrylic sealant, see the following video.