How to make a bunk bed for children with their own hands?

Hand-work has recently become more and more appreciated and is gaining popularity due to the irregularity of the solutions used. This also applies to furniture. A rather time-consuming process, requiring patience and some skills, may ultimately please with its results even a beginner. There are many ideas for creating the most diverse garden furniture, including sofas from wooden pallets. Equally atypical approach can be implemented also in the manufacture of home furniture.In this article we will talk about how to simply make a bed in two tiers on your own.

What is good handmade furniture?

A self-made bed is always better than a purchased one in a store. And a lot of reasons for this. In the first place - the quality of the material used in the work. Choosing it, any master will take into account parameters such as reliability and durability. Therefore, at the end of the work, he will have confidence that his product will last long enough and will not disappoint with durability at the first use. It happens that the store can not find the right thing. For furniture, this situation is particularly relevant: the size of the object may not be suitable, the design or the types of materials used for the frame and decoration may not like. The question arises about what is better: order an individual production of things or take up the work yourself. Sometimes the choice of the second option is preferable, because in this case there is no need to search for a good master, explaining to him his ideas and paying a considerable amount for the work. But the main advantage of any thing made by hand is, of course, special sensations both during work and in the process of using the product - it is always nice to feel like a creator.

Let's sum up. Creating home furniture with your own hands, you can win on several points:

- cost;

- quality characteristics of the materials used;

- unique design;

- individual parameters of the product.

Species

The scheme for making such a bed is not very complicated. Such a two-story bed and a ladder can be made of different materials, for example, from plywood or laminated chipboard. Also do not forget in the project about the decor and stylish curtains. If the decision that the bunk bed needs to be done independently, has already been made by you, then you can proceed to the work. However, you first need to understand the set of existing models of bunk beds, having considered the most popular ones.

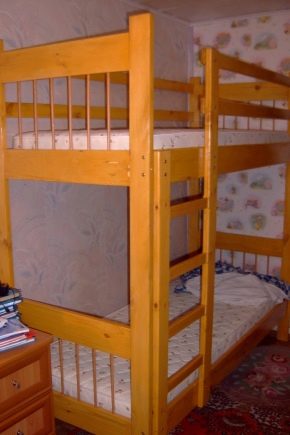

Classic

Make it easy. The design of the product includes two places for sleep, located at different levels from the floor. There is also a side staircase. Typically, as a furniture, such a model is placed in a large children's room.

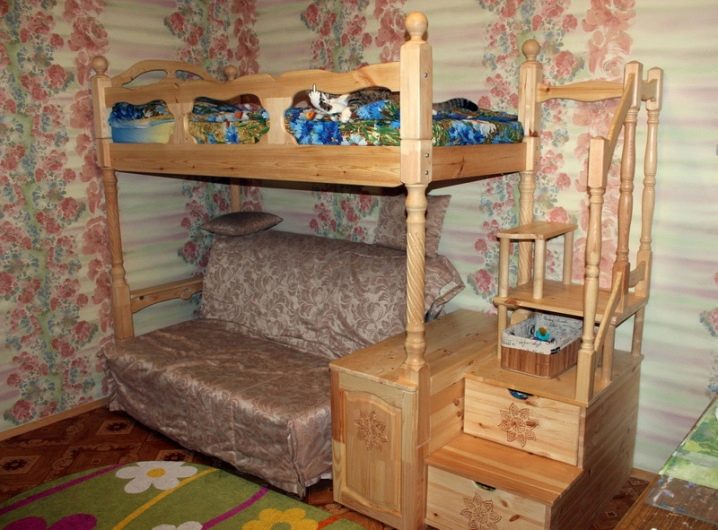

With a sofa

The presence of the sofa part located on the first "floor" is an excellent solution from the functional and aesthetic point of view. Such a model can be put in a room of almost any size, and it will be used by households not only as a bed, but also as a cozy place of leisure and recreation.It is quite appropriate to arrange such a convenient design in one of the corners of the living room.

With functional details

In order to maximize the ergonomic use of the area of a small room, you can fill the space formed under the stairs to accommodate various household trifles. The size of this bunk bed is usually much larger than the classic version, but the efficiency is higher.

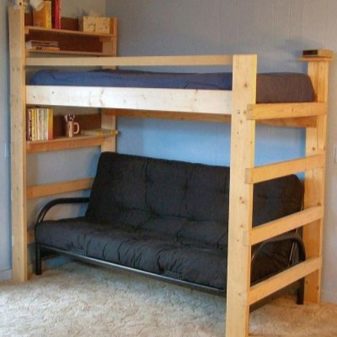

Attic

Great design for a small nursery. The second floor is a classic place to sleep, and the first is used as a study. They place a desk, shelves and plan the right lighting. Such a model may appeal to adult children seeking to have an individual space. It is usually made single, although if necessary, the size can be provided for more (taking into account the placement of two people). This bed has a variety of location options: traditional or in the corner of the room. The main thing - to provide the strength characteristics of such a product.

Bunk three-sleeping bed

To make the traditional model three-bedroom, use small tricks.For example, if there are babies in the house and limited living space within a small room, it is logical to place a double seat at the bottom. If the bed is made for a child, then the bed is at the top.

Convenient transformer

Very popular model of extremely ergonomic design. Usually, in addition to the bedroom, it also includes a disassembling place in the form of a sofa or table. Individual elements are made collapsible or retractable, for example, a table.

What materials are used for the frame?

There are many types of wood suitable for making beds.

Consider the main ones.

- Non-glued board (array). This is a very expensive and difficult material for use in manual work by beginners, requiring special preliminary preparation. It is better to have some experience for working with an array. The advantages of using it are that the products made are long and beautiful. Given that children grow rapidly, this requires a review of the issue of their placement, so it is very uneconomical to use expensive material for the manufacture of their furniture.

- Planed board, bar, edged board - the most common in the manufacture of furniture materials, characterized by ease of use. When selecting them, it is only important to take into account the quality of drying in order to exclude structural disturbances in the already finished product.

- Fine wood fraction in the form of a plate (MDF). It is completely safe material with the same emission of formaldehyde, as in the first two types of materials. The features of working with MDF include the fact that when drilling it forms not sawdust chips, but dust. Usually MDF sheets are laminated to give an aesthetic look. If you use MDF without decoration, it is necessary to at least lacquer them. As a rule, cutting of parts from this material is ordered in workshops where there is a special sawing equipment. Masters can also stick the edges at the cut points.

- Wood chip plate (chipboard). Since the release of formaldehyde in such a material is increased, with the exception of E1 class plates, products require a hermetic coating. Features of use: the material is easy to cut, but absolutely does not hold the attachment. It is best to use it in the manufacture of light structural elements, which will not act load.Plate chipboard, pre-coated with laminate, suitable for the manufacture of backs and panels of the finishing nature.

Required tools

If the master made a decision to entrust the cutting of materials according to the drawings and measurements to furniture makers, then there will be not so many tools needed for work. And at the end of the cut the main task will be only to assemble the bed.

For this operation, you need the following tools and parts:

- screws;

- screwdriver;

- level;

- glue;

- hammer;

- drill;

- sanding machine;

- already sawn parts of the product.

Completing of the work

If the preparatory stage is completed, it's time to start assembling a bunk bed.

- The foundation. First, construct a frame, that is, a rectangular box in which the mattress will be placed.

- Tsargi The base of the bunk bed is made of sawn according to size and then polished parts. Perpendicular to them join a smaller width of the board. Thus it turns out something like a shelf.

- Little bars. They are fastened with screws to the tsargs. Between them lay the boards that will hold the mattress.

- Strengthening the frame. On the short sides of the bed you also need to make shelves on the inside of the resulting rectangular design. To do this, the boards connected by a shelf are fastened to the tsargs with self-tapping screws by means of a secret fastening.

- Boards that are laid out between the king, must be sturdy to withstand sufficient weight.

- Installation of backs. The backs are attached to the racks. Their width is usually equal to the width of the bed. There should be three backs: at the feet, at the head, and at the part of the bed that will stand near the wall. Pins are used for fastening these elements - these are wooden wooden bars of circular cross section, their diameter is determined by the thickness of the drill. Having drilled the holes of the required diameter in the back and racks, they put the dowels.

- In the same way is the bed of the second floor. Then a ladder is attached to the carrier rack. Additional backboards are also being built as fencing on the top floor. If the design features of the product require storage under the stairs, then it is mounted on the outside of the rack.

Finish

Decorative design of the bed should be provided at the design stage, as it may affect the sequence of stages of the work.Experienced craftsmen make beds of fancy shapes and taking into account the wishes of the baby: like a hut, car, boat. The ladder is sometimes replaced with "lianas", climbing on which the child will imagine himself Mowgli. And an experienced carpenter will make a bed in the form of a fabulous home from favorite children's books.

Additional elements can also be added to the bed.such as wall bars, rings, climbing panel. Very popular design details are the slopes in the form of slides from children's playgrounds. The master with the imagination of the power of the embodiment of any design of the bed for the child, as well as decoration and decoration of its panels. But you can also decorate the product with textile trinkets: pillows, pendants, ropes. Making your own bed in two tiers is generally easy. And the advantages of such work can be a benefit in price, an individual style and the joy of the household.

One can only wish success in this interesting creative process!

How to make a bunk bed for children with their own hands, see the next video.