Rules for installing the furnace in the bath

The installation of the furnace is the most important stage in arranging the bathing space. Effective warming up of the steam room can be achieved only with the right approach. To understand the process, you need to consider the details of the installation of the furnace structure, as well as the algorithm of all the work.

Special features

Furnaces for a bath are made taking into account the following parameters:

- minimum sizes;

- warming up speed;

- minimum amount of fuel;

- optimal price.

An important feature of the sauna stove is the rate of heating the room. Therefore, attention is paid to the choice of matching the dimensions of the unit with the parameters of construction. It should be borne in mind that steam is an important component for the steam room, and for the entire building.

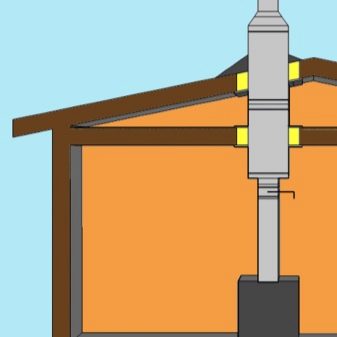

The heating rate is directly related to the proper preparation of the place for the furnace. Its classic location in the bath should provide heating for all premises of the building. The features of these events imply the obligatory equipment of the external fuel channel.

The layout of the unit requires extremely careful insulation of structures. This work should be prepared taking into account the fact that the highest temperatures rise. Especially hot in the chimney unit.

The choice of location for the stove in the bath should be due to a number of the following factors:

- structural features of the stove;

- principle of the device.

The possibility of a choice of a place the iron bathing stove with a portable fire chamber a little limits. But modern versions have equipment in the form of a telescopic firebox. If necessary, the length of such a firebox is permissible to increase, so the choice of location options are also expanding. For uniform heating, the stove is installed taking into account the spread of convection currents. The best option for placing the stove is in the steam room, with a firebox in the dressing room. Thus, you will achieve heating of two rooms at once.

The optimal cost of the device can be achieved by self-manufacturing stove for a bath.

Required tools

In the process of planning the installation of a bath stove, one must take care not only of efficiency, safety and functionality, but also of the necessary tools.

To improve the quality of installation, you should first prepare:

- steel sheets (8 mm thick);

- pipe with a circumference of about 50 cm;

- bars from metal, with a section of 100 mm;

- the grid-iron, furnace, doors blew;

- chimney;

- hot water taps;

- tank under water in a volume of up to 1 cubic meter.

For installation of the structure, a welding machine, a Bulgarian will be useful. It is important to choose all the completing materials in accordance with the existing construction regulations and building regulations. For example, galvanized asbestos pipes are not recommended for use.

How to set your own hands?

Choosing the correct location of the stove, take into account the location of the components that should be available for periodic monitoring. Reliable and high-quality pedestal will serve as a screed with insulation, poured over a primed base, at the same time the construction phase with the foundation. If the floors in the bath are incombustible, for example, from cement or concrete floors, no additional protection is needed.Fire retardant materials are used only for wooden floors.

If the soil at the site is heaving, you do not need to lay for the stove, not connected with the foundation on the screw piles of the slab pedestal. It may be associated with the base of the bath if the device is shallow. For the bundle, anchoring of the bases and the furnace and the bath is performed.

Rules for the arrangement of the pedestal for the stove

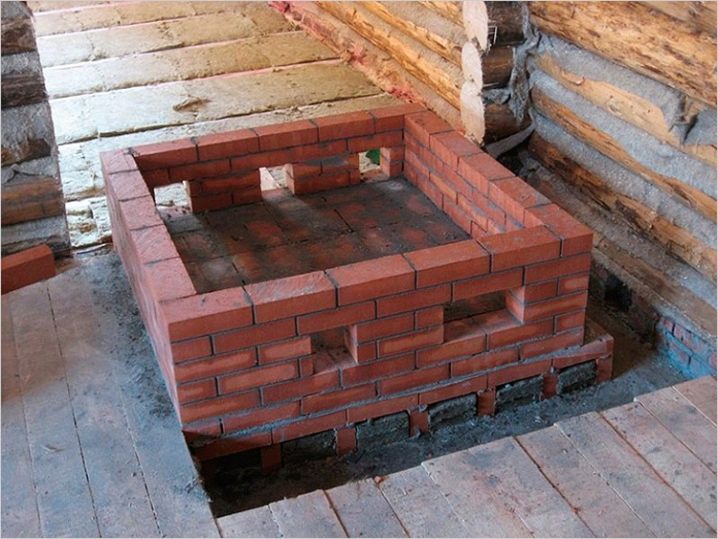

The dimensions of the base should be more than the size of the stove made of metal with protective screens 20 cm. The height of the base should be equal to the depth of the bath foundation. The free part is permissible to fill with brickwork.

Technological step-by-step process involves:

- Preparation of the pit.

- Formwork installation.

- Laying armwork.

- Pouring cement mortar.

- Covering the base with a layer of waterproofing.

- Laying bricks in several rows.

You can avoid installing a separate pedestal under the heat exchanger, if the lag and the base of the floor are strong enough to hold the weight of the structure.

Solutions:

- laying a sheet of metal on top of the basalt sheet;

- laying brick or stone base under the stove;

- laying ceramic or porcelain tiles.

Vertical parts that will come into contact with the structure are protected by heat-resistant sheet material. Specific values of the parameters are indicated in the instructions of the manufacturer of the bath stove. Values are interconnected with the real thermal level of the stove and its structural nuances.

Remote Channel Furnace

Consider the installation of a factory stove-heater with a remote fuel channel, is the best suitable for a country bath.

Standard instruction involves the following stages of work:

- arrangement of the opening in the wall;

- thermal insulation of the stove;

- fire protection of walls;

- installation of chimney construction.

The site near the structure is covered with clay, cement mortar or liquid glass. On this basis it is already permissible to put the stove. The place for the stove is exactly consistent with the direction of the chimney. In the wall, next to a specific place for it, an opening is being prepared. It should be more than the size of the ash pan.

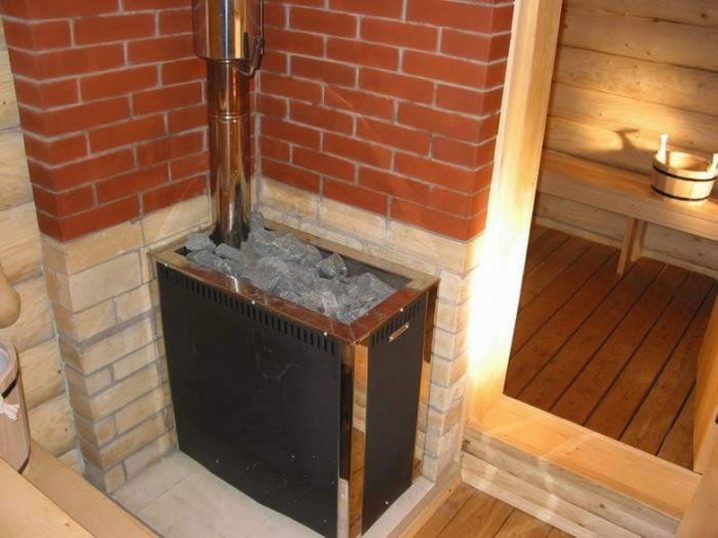

The surface of the wall is protected by bulk-type mineral insulation. Heat-resistant material is finished wall adjacent to the body of the stove. In the frame baths, as well as in the construction of the timber, the junction area is laid out with bricks.Thermal protection tiles are glued over the masonry. To fix the furnace, special loops are used, fastened with anchors.

The ideal chimney should not have turns and knees, and the first meters are necessarily of heat-resistant steel. For the pipe, it is desirable to have a body of heat insulating material. Standard straight pipe is led through the roof. Therefore, in the roof, in the designated points, mounting apertures are prepared. The space around it is filled with mineral wool and asbestos sheet. The pipe is closed by a casing.

In general, with the right approach, the installation of the stove will take two to three working days. However, you can use it no less than seven days. It is necessary that the laying under the foundation, protective systems receive the necessary degree of reliability. Filling stones Kamenka is possible only after 14 days. During this period, the pedestal under the furnace will shrink.

Metal oven

Metal stoves for steam rooms are on the wave of popularity. Iron models are wood, coal and other types of fuel. One of the positive qualities of the design is its small size. The unit is optimal for location in small baths.

For the purchase of the furnace, even cast iron, often does not require a monolithic plate under the base. Another positive point - in a small metal structure, heating is faster. A brick oven, for example, will warm up for 3-4 hours. But the brick stove provides more uniform heating of the premises.

Forms of metal stoves are:

- vertical;

- horizontal;

- barrel-shaped and other interesting configurations.

The design implies the obligatory presence of a hot water tank and a grid for the heater.

Heaters

The heaters with a separate steam bath create an ideal microclimate for visitors. Therefore, the construction of the heater is given maximum attention.

She must be:

- productive;

- safe;

- compact.

Rules for the arrangement of the heater imply the presence of:

- metal foundations;

- guides for dissecting steam flow.

Bath stones are usually laid on a waterproof base.

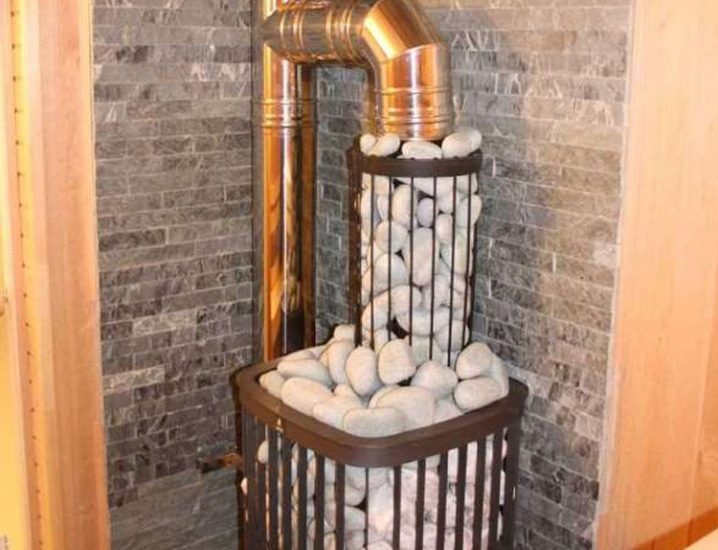

Stoves-heaters are a type of permanent firebox. Unlike other types of stoves, the stone bookmark accumulates heat better, as it acts as a kind of evaporator.A liquid is poured on the surface of the stones, which is transformed into steam by the action of heat.

At the same time, if a waterproof stove is installed above the firebox, steam can be obtained in the process of burning wood, and they will not be extinguished with water. If the heater is located in a simple crate, steam can be obtained only after complete combustion of the fuel.

The temperature of the stones in the first variant of placement can reach up to 600 degrees, and in the second variant of placement up to 300-350 degrees. It is believed that with optimal placement of stones, a soft steam should not burn or obstruct breathing.

Tips and tricks

Despite all the limitations of fire safety, the layout of the bath stove inside the steam room is allowed to be different. For example, if you move the device to a corner, you can free up a sufficient amount of working space. Placing the furnace in the middle of the wall will allow you to install benches and shelves on the sides, increasing the number of seats. However, the latter option is not very convenient to maintain and during bath procedures.

The installation instructions for the stove in the bath assume the maximum approximation of the unit to the wall.In this case, the distance to combustible materials of the walls should be at least one meter. The rules for installing the unit in the finished bath involve marking the place relative to the lag. Thus, a uniform distribution of the load on the supports will be ensured.

Wooden surfaces are covered with a protective base, which will provide high resistance of wood to temperature differences. The efficiency of heating is better if the furnace part is very close to the base. Some craftsmen even specially set the oven, deepening it in the floor by 10-15 cm so that the boards become warm. When installed below the floor of the furnace is inconvenient to lay firewood in the furnace.

Manufacturers and reviews

Individual companies usually specialize in the production of heating and sauna stoves. For example, "Thermosphere" known for its units, which are sold on the market for over four years. Products are made of thick-walled materials using innovative technologies.

The best option of the furnace for a bath from this Bashkir company "Gorynych 3". The model is equipped with a longitudinal combustion system that provides heating of the entire bathhouse without an additional boiler and radiators.

Another well-known manufacturer in the domestic market is the company. "Teplodar". The most popular model of this company. "Taiginka 16 T". Small in size design will heat the steam room to 16 cubic meters. In this case, the system is designed so that both the shower room and the rest room of the small bathhouse will be warm. Reviews of the stove in most positive.

Ovens "Ermak" presented on the market a number of designs with different features. Heating equipment can work on wood, electricity, gas.

Known variations:

- "Ermak 12" - designed for 6-14 cubic meters. m steam room;

- "Ermak 16" - 8-16 cub. m;

- "Ermak 24" - 12-24 cu. m;

- "Ermak 30" - 15-30 cu. m

Users mark the special attractive design of domestic manufacturers of furnaces. "Barbara". These devices have secured a stable demand for themselves and have no complaints. Enough good feedback from the company. "Hephaestus", producing solid units for baths up to 120 cu. m. The main advantage of these devices - high quality, reliability and good performance.

Successful examples and options

The oven, located inside the steam room in the center, with benches and shelves on the sides.

A stove installed in the corner of the steam room, equipped with a heater to create a soft steam.

Metal bath stove with a metal fire screen that is built into the wall itself.

Sauna stove, lined with brick. This option will protect against burns. The heat of the furnace will not decrease due to the air gap between the casing and the finishing material.

For tips on installing a stove in a bath, see below in the video.