How to make a stove for a bath with your own hands?

Most of the owners of country plots, along with the construction of the house, the ennobling of the adjacent territory, are planning to build a bath. Someone more convenient to use the services of professional craftsmen, but for someone a bath, built with his own hands, has a special indescribable value.

The main element of the bath is the stove. Despite the large number of important details, it is quite possible to design it yourself, if you study all the subtleties and nuances of the furnace business.

Special features

With all the functionality of the furnaces, the requirements for different models will be different. Bath stove should have high efficiency. Since it should take up little space, it should have enough power to heat the steam room to significantly high temperatures, heat up quickly and keep the heat on for a long time.

The design of the stove is not so complicated, but there are a number of significant conditions. A very important parameter is the safety of the furnace.. For example, the so-called hot oven raises the temperature of the bathing room in a short time due to the fact that its walls are heated to a temperature of up to 100 degrees Celsius.

If you carelessly touch this hot surface, the burn is inevitable. Moreover, in this case it is impossible to control the degree of heating, which is fraught with great stress for the body and even heat stroke. Unlike conventional furnaces for space heating, there are additional elements in bath stoves, such as a heater or water tank.

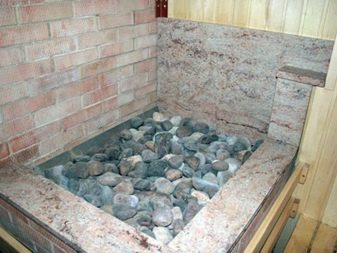

Kamenka represents capacity in which cobble-stones of the different sizes keep within. When heated to high temperatures, they contribute to the retention of heat in the sauna room, and are also direct generators of steam. Stones are poured with water, evaporating water creates the necessary humidity and a comfortable atmosphere in the steam room.

The water tank can be equipped with a tap for greater convenience. In the absence of a central or other water supply in the bath, a container with hot water becomes a necessity for taking bath procedures.

Species

There are a large number of models of furnaces that can be made by hand. They differ in different characteristics. In general, conditionally sauna stoves are divided into two types - cold and hot. The hot oven, as noted above, heats up completely, including its own walls, hence it spreads heat to the entire room of the steam room. And if such a furnace has a minus in that the room will overheat, then a cold furnace will not have such a problem due to heating only the firebox and the stones in the heater. But in this case, an additional source of heat is needed, especially in winter.

There is a high probability that such a centralized heater will not cope with the large volume of air in the bath.

The next characteristic is the constancy of heating. there is continuous heating furnaces, they are heated during bath procedures for an unlimited time. It is not necessary to heat it to very high temperatures, it is enough to constantly maintain a given level by throwing firewood. With constant heat, the heat and humidity are stable, the room is comfortable.

Periodic heating furnace properly heated before visiting the bath. After this, the bath will keep the resulting temperature for a long time due to the stones that are inside the heater. An interesting additional effect from such a furnace is the smell, very pleasant with the notes of wood, which arises from the settling of wood soot on the stones.

To make the right choice, you need to figure out how different furnaces are characterized.

By production material

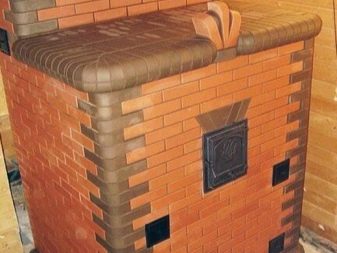

The first model to pay attention to is brick stove. Experienced builders recommend this material as the most optimal for a bath. The biggest advantage is the quality of steam, which is obtained from the heat of this furnace. The heat generated by it is soft and uniform, so the steam is dense, hot, but not burning.

Another nice nuance for owners of aesthetic taste - brick can create an unusual or classic interior solution, so the furnace of the bath will be not only a useful, but also pleasing to the eye structure.

At the same time, you need to pay attention that brick oven requires free space. There are, of course, small-sized structures, but more often the dimensions of such a furnace are quite large. In addition, for its installation will need an additional foundation, since the furnace is heavy, which can also affect the free area of the bath.

Brick furnaces, in turn, also come in several forms. Depending on the characteristics of the building, the stove will be called “in white”, “in gray”, “in black”.

Bath "in black" known in Russia since ancient times. Once it was the only option for arranging a bath and it was believed that her visit brings health, kills the ailment and strengthens the body.

The bottom line is this: in the sauna room a stove is built of stone and rubble. This stove does not have a separate chimney. Due to the simplicity of their design, such furnaces managed to be designed even in the marching military life, organizing baths for soldiers. That is, the furnace is melted, the firewood is thrown up constantly, in order to achieve strong burning, smoke from burning firewood goes directly into the room.

It takes a few hours to warm up the stove and the room thoroughly. After this, the room is ventilated and ceases to sink.Of course, the bath will not be able to retain heat for a long time after the fuel burns through, but, as a rule, this was enough for washing.

After such procedures for heating everything in the bath was covered with a layer of soot, shelves, walls, all possible surfaces. Soot was washed with water, and after the stones were poured with broth of mint, pine needles. It was believed that it was in this way that all bacteria and microbes were destroyed., and the air with the smell of wood and burning is very useful.

Now many adherents of the “black” bathhouse are reappearing. They argue that such a bath is really real, and everything else that exists at the moment is only a parody and does not carry any value for health and good spirits.

But there is an opinion that such a bath can be organized only by professional bath attendants, and for people who do not know all the subtleties and nuances of the bath business, it can even be dangerous.

For arranging the bath "in gray" A chimney pipe is added to the simplest design of the stove. Thus, smoke and carbon monoxide no longer enter the steam room, but at the same time the heater is mounted in such a way that the smoke goes out through the tank with stones. In this case, after watering water on the stones, steam is obtained with an admixture of smoke.

Soot in the bath will be gone, but the unique bathing atmosphere will remain. This option may be suitable for lovers of this Russian bath, who want to avoid the minuses of the bath “in black”.

Bath "in white" will warm up longer than all listed. But its worth is that she keeps warm for a long time.

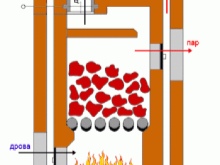

Hearth furnace - another original type of brick bath stove. It differs from standard furnaces in that the air is accessed from burning firewood from above, not from below. If in the usual version of the firewood stacked on the grate and set on fire from the bottom, then in the hearth furnace, ignition is performed from the top and the direction of thrust will change to top to bottom. Such a device allows firewood to flare up evenly and maintain a certain temperature for a long time, unlike furnaces with lower burning, where firewood flares up sharply and intensively, but also quickly burn through.

The laying of firewood in the hearth oven should occur in a certain way: large logs are placed at the very bottom, then the middle ones, and very small chips at the very top. Designing a stove with a top burning,You can refuse to install the ash pan, because with this method of burning ash after the end of the burning, you can simply sweep the broom on the scoop.

A metal furnace is a fairly common option.. It has small dimensions, can be both square and round, it quickly heats up and cools quickly. Such a furnace can be bought finished, and it can be welded from steel sheets, having a little welding experience. Moreover, it can be made even from recycled material, for example, scraps of pipes. It is easy to burn metal on metal, so for security reasons you can enclose it with a layer of brick.

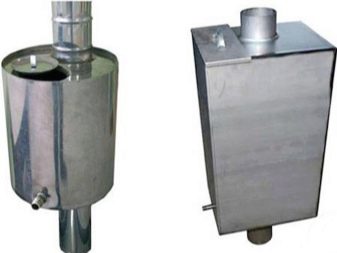

One of the varieties of the metal furnace is the bath boiler. If the metal furnace can be of any shapes and sizes, then the boiler is, as a rule, a cylindrical structure, small-sized. The boiler can be placed in the bath room as a source of additional heating.

The implementation of such a structure is done by hand using an algorithm for all metal furnaces. The sheet of metal is cut in shape, the body is welded, the firebox and the heater, the chimney is equipped. After that, the boiler can be lined with bricks so as not to risk burning yourself with a red-hot contour.

By location of the furnace

The main technical element of the furnace is the firebox.It can be located inside the steam room, and outside.

If the firebox is inside a steam room, it can be convenient because you don’t need to go far to add heat. But at the same time, given that, as a rule, a steam room is small, there is a great danger of getting burned.

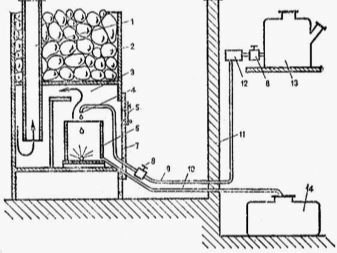

Remote heating - a much more convenient and safe choice. In this case, there is a sauna stove in the steam room, possibly with a tank of water, and the fire chamber was moved to the dressing room. Obviously, with such an arrangement, the possibility of scalding is minimized.

To install a heat exchanger for the bath - a special single element for heating water, you need to focus on the location of the furnace, because it can be located in the chimney or in the furnace itself.

By type of fuel

This bath, of course, is heated on the wood. It is firewood - an environmentally friendly material that creates the very wellness atmosphere for which everything is being started. But there are exceptions.

The furnace can run on gas, “fuel” can be electrical energy, and in other cases, a liquid combustible substance such as diesel or diesel fuel. When working out such options it is important to remember that these products are toxic and if it is decided to heat the bath exactly this way, be sure to bring the combustion system to the street.

Electric furnace - An interesting option for those who do not want to put a lot of effort into the preparation of the bath, does not like to follow the heating process. A possible disadvantage of such a furnace can be the fact that it is absolutely not economical. But for those who are ready to sacrifice the atmosphere of the Russian bath in favor of convenience and comfort, such an oven can be an ideal option. From such a furnace will not be soot, there is no need to arrange a chimneyand the most important advantage is that you can set exactly the heating temperature that is ideal for you.

The electric furnace is purchased in finished form and installed according to the instructions. If everything is done correctly, such a furnace will be absolutely safe in operation, the heating-cooling modes will be adjusted automatically, and it is very convenient to control all its functions using the remote control.

Gas oven also has a lot of supporters. It features easy installation, ease of maintenance, safe when used correctly and very compact.The furnace of this type is equipped with a gas burner. There are models equipped with a water tank, a tray for stones. In this design, there is necessarily a fuse that will not allow gas to spread if the fire suddenly goes out.

At installation of the gas furnace it is necessary to be guided by safety rules. The main requirement is the remoteness of the walls of the furnace from the walls of the room (at least 50 cm). The foundation under the furnace should exceed its circumference by a minimum of 10 cm. It is also necessary to pay attention to the size of the burner - they must fit the size of the furnace. The main advantage of the gas model is its economy and durability. Gas ovens can last about 25 years.

The furnace itself is a high-risk device, Furnaces operating on diesel fuel, diesel fuel and mining have a very high class of danger.. At the same time, such a furnace is the only option that can very quickly heat a very frozen room, which can be a great advantage for those who visit the country bath several times over the winter, for example.

Having decided to install such a unit, it is necessary to resort to the help or recommendations of specialists.Since in such a furnace the oil product is heated to high temperatures, if the wrong approach to the device of such a furnace is possible, fuel may burn up or explode.

The diesel-powered furnace can be dual-circuit, wick and drop. Dual-circuit is a kind of heat gun, which instantly warms up even the most ventilated room. Fuel consumption for it is very high, so this type of furnace is not particularly relevant for installation in the bath.

A wicker stove is more a marching design.. If you want to use it for heating, you need to make sure that all its parts are made of high quality materials and carefully fitted to each other. But such a device has a very small power anyway.

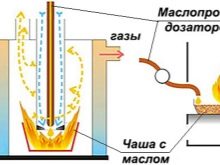

Drip oven that runs on a diesel engine - the best optionwhich can be used for the bathing room.

The principle of operation of such an apparatus is that fuel is dripping into a container with a hot evaporator. The stove is started using a burned wick, the evaporator is heated. After almost complete burning out of the wick, the droplets of fuel are started.Getting into the capacity of the evaporator, the drops boil and the steam lights up, generating heat.

Already available stove- "stove" can be successfully altered under this type of fuel. Be sure to carry out all work in strict accordance with the scheme, made in compliance with all safety requirements.

By way of heating

The next important characteristic of a bath stove is the type of stove device on which the method of heating stones depends, which means temperature and steam in the room. Everything is simple here.

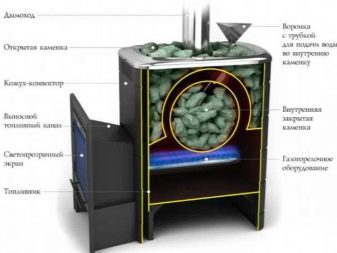

Kamenka happens open type and closed. In the open type, the stones are placed above the fuel compartment. Hot water is poured on them in order to get steam. This is suitable for small rooms, because with frequent watering of stones with water, the stove cools quickly. If the stove is equipped with a water tank, this design will be more convenient, since everything will be at hand.

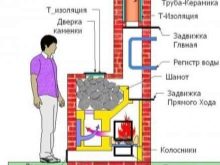

Closed type stove - a better option for many reasons. In this design, the stones are located behind the door. It will take more time to warm the bath, but the stones can store heat for up to a day.

When the type is closed, the fuel compartment is located outside the room, thus eliminating the possibility of carbon monoxide in the steam room.The entire furnace is heated equally, which creates a mild atmosphere of uniform heat. With this arrangement, the stones are less able to burn themselves with hot steam when they are watered.. Behind the closed door, the stones keep their heat for a long time, so the temperature in the bath will remain high for a long time.

There are also original models of stoves that can be purchased and installed. These are standard designs which are improved on various characteristics. For example, akvapech, which retains a sufficient amount of oxygen in the steam room due to the water layer, which is laid in the walls of the furnace.

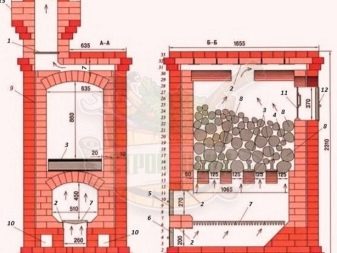

Kurin's furnace is a type of brick furnace for a bath, which has its own characteristics of a device for a more comfortable and uniform heating of the bath room.

Subtleties of manufacture

It is easier to make a metal furnace with your own hands, but with a great desire and the presence of patience, you can also make a brick one. Before construction, you need to have a general understanding of the basic requirements for building a stove for a sauna room.

The furnace must be installed against the wall, which is located opposite the one that is equipped with shelves. The chimney pipe cannot be designed so as to be able to adhere to the ceiling surfaces, it is necessary to leave a gap, which will then be filled with refractory material and covered with a protective lining. A sheet of metal is placed on the floor in front of the fuel chamber to protect the premises against the likelihood of fire.when coals wake up from the oven.

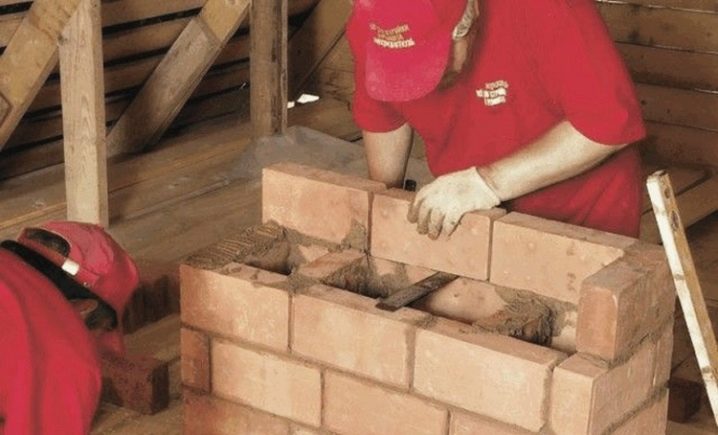

Brick

The most common designs of stoves for a bath of bricks, which can be made by yourself, also differ in the location of the tank for heating water. There are stoves with the installation of the tank below and stoves with the installation of the tank above.

Before you start building the stove, you need to prepare the necessary materials:

- brick itself;

- clay and sand;

- mixing solution bowl;

- marking and laying tools;

- insulating materials;

- Separately, you need to prepare materials to create a tank for chimney water, if you decide to do it yourself. You can also buy them ready.

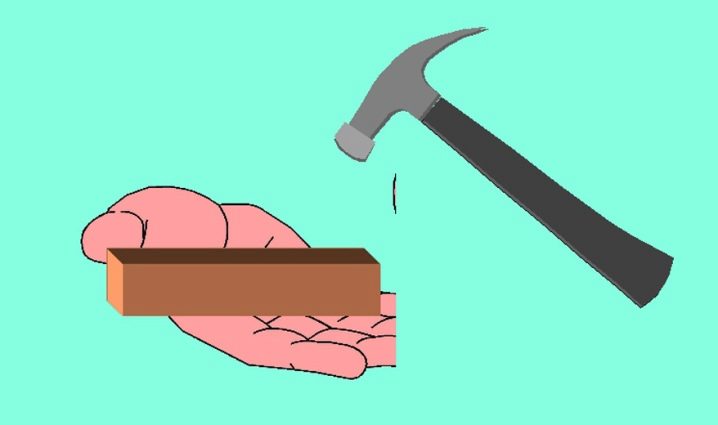

To build a stove that will be installed in the sauna room, brick must be purchased of higher quality than normal for construction. It should also have refractory characteristics and have clear shapes and the same size.

So-called chamotte brick - in its parameters the most suitable option for the stove, standing in the bath, but it is necessary to take into account the fact that its cost will be much higher than ordinary brick, therefore it is possible to use it partially, in the most significant places, for example, for heating - the place of greatest heating. And for the outer walls, chimney and trim can be used ordinary red brick, but not of poor quality.

You can easily test bricks by knowing a few simple ways. The first tentative parameter will be sound. If you hit it with a hammer, the sound coming from the surface should be ringing and clear. If the sound turns out to be deaf and as if going inside, it is likely that inside the brick there are cracks that make the brick fragile and fragile. In this case, your furnace runs the risk of collapse after a short operation.

The second indicator is the appearance of the brick. By standards, the brick should measure 250 * 120 * 65. Deviation in the normal range is considered to be 2 mm.There should be no visible defects, cracks and chips on the brick. Minor presence of grooves is allowed. Sometimes on the surface of the product can be seen bloom, reminiscent of the film. It is worth refusing such brickbecause it indicates a defect in production. Such a brick will not be fixed in the right place, as the film will prevent the necessary adhesion.

The third landmark inside the brick. In the true sense of the brick must be divided into two parts and carefully examine the surface of the chip. The color should be uniform and not have darker veins and inclusions. Their presence indicates a violation of technology in the manufacture, burning brick. Such a brick for the construction of a bath stove is absolutely not recommended to use.

Starting construction, you need to properly establish the basis of the future furnace. The base must be made waterproof to keep it cold. A sheet of roofing material is perfect for this purpose.

The foundation should be more than a furnace approximately 10-12 centimeters. It is covered with a beam of concrete or steel and a flooring will be installed on top of this overlap.

Next, you need to prepare a solution that will link the bricks together. For the mixture will need clay, sand and water. It is advisable to use clay the same as that used in the manufacture of bricks. It must be mixed with water and left for a day. Sand is added last. The consistency should be homogeneous and thick.

To understand whether the mixture is prepared correctly, you need to trowel it to the side, on the surface. The mixture should not crack, spread, stick to the trowel, the solution should keep its shape well. There is another way. Wooden stick to dip into the solution. The layer of the mixture, settled on a stick, should be no more than, but not less than 2 mm. It is better to prepare the solution in small portions.by making a new batch after using the previous one.

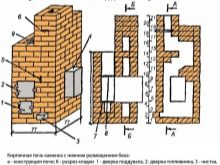

After the installation of the foundation, starting the laying, you need to have before your eyes the drawings on which the work will be performed. The scheme prepared in advance, according to which brick will be laid, will greatly simplify and streamline the process.

Brick laying is standard and rarely performed otherwise. The first rows of bricks are stacked, as a rule, in a continuous layer, this will be the so-called kiln cushion. Two rows will be enough. The third row begin to lay, based on the drawing. Here the grate, the blower door and the ash compartment are usually laid. The blower door is installed using galvanized wire. The door is mounted in the middle of the wall, and its lower segments are laid out on the surface of a row of bricks. The wire is hidden in the grooves made on the surface of the bricks. And the upper part of the door will be fixed in the sixth row of bricks.

Next, four rows of bricks fit in a row. Here need to pay close attention to the alignment of the corners. The correct installation of the ashpit and the grate depends on this. If at least one corner is wrong, there will be a possibility of smoke entering the steam room.. After laying the solid rows, the top of the door blends, on the sixth row of the masonry.

The seventh row of bricks is the level at which the fire door and the grate are installed. The grate grate should be flush with the brickwork; for this purpose, recesses along the height of the grate rods are made in the bricks.The grille is fixed with a mortar. The grate is tightly placed on the layer of the mixture and knocked with a hammer for a stronger grip. The grill should not be allowed to come into contact with the walls of the stove., because the grate when heated will increase in size and create pressure on the side surfaces, which is fraught with destruction of the furnace. The door of the firebox is mounted similarly to the door blew.

Next, you need to make an opening under the water tank. Considering that the tank will come into contact with the brick in some places, for the best fastening it is necessary to wind the tank with an asbestos wire cord. The tank is placed on the side walls.

From the next row of masonry, namely the eighth, the chimney will begin, therefore it is necessary to install a partition there. The ninth row is already mounted water tank itself and set the stove. Then the brick is installed at the height of the furnace and after that the chimney is laid out according to the scheme.

The water tank can also be located above the chimney. But it is obvious that, being located directly above the furnace, the capacity will warm up much faster.

Metallic

Metal furnaces have their undeniable advantages.For example, easy installation and quick heating. This also includes the small size and aesthetic appearance. But with all the advantages, we must not forget that the metal furnace will be more demanding in terms of safety. Therefore, conceiving the installation of a metal furnace, you must strictly follow the instructions and follow all installation rules.

The oven is installed at a distance of at least 0.5 meters from the walls and interior.

If the metal furnace will work with the help of electricity, be sure to ground it. When choosing such a heating option, coordination with the fire inspectorate is also necessary.

The ceiling and walls of the bath need to be protected from fire by laying an insulating material. or by finishing brick and / or metal sheets.

Stone or masonry can be laid over the walls of the stove, reducing the risk of burns. An additional advantage of this lining will be an increase in the heat retention time in the furnace.

Since the metal furnace has a small weight, as a rule, it is not necessary to build a separate foundation. Such a need may arise when the weight of the furnace is more than 750 kg. In other cases, it is enough to lay a sheet of metal on the place of the future furnace or even to lay the usual ceramic tile. This layer is made in order to fire safety.

The furnace itself can be purchased in finished form, but with at least a small knowledge and skills, you can also weld yourself from sheets of metal.

In the case of a furnace for installation in a bath, you need to understand that the metal should be tested for strength and possible deformation when exposed to high temperatures. In order to avoid such surprises, it is necessary to heat metal sheets red hot and see what will happen to the sheet.. It may increase in size and lose its smoothness. Then with a hammer the sheet is tapped over the places of the hillocks and hollows to the original appearance, and the surplus is cut off. Such preparation will not allow the furnace to warp during operation.

The metal furnace most often does not provide in the design a tank for water. Since the stove itself is small, the additional capacity will make the structure more cumbersome, depriving this option of its obvious advantage for small rooms. But of course, if necessary and desired, the tank can be provided.

Anyway, the tank needs to be picked up in small sizes, since it has to warm up in a short time.

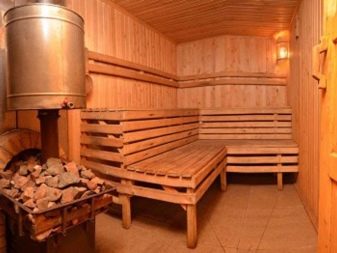

The stove in such a furnace can be internal or external. If the heater is installed outside, you can pour water on it to get steam. It looks aesthetically and beautifully, warms up to high temperatures.

Internal type heater allows stones to warm up more.accordingly, they will retain heat longer, but in this case, the path of the chimney will lie there and there will be a need for periodic deep cleaning of the heater from settling combustion products.

Stones themselves are of great importance for a self-made metal furnace. Granite cobblestones are absolutely inappropriate material.. They contain inclusions of mica, which, when heated, releases toxic substances. Inhalation of these toxic fumes is very hazardous to health. It is best to use conventional natural stones, round, approximately the same size, without cracks and chips..

In specialized stores you can buy cobblestones from basalt or jadeite, which are perfect for a bath stove.

In addition to the correct choice of stones, it is important and correct to fold them. The largest and heaviest need to put on the bottom of the heater, given their shape. If the stones are oblong, they are laid vertically so that the heat going up can pass along the surface of the stone. If we neglect this rule, a natural barrier will arise for the heat and the lower stones will be very hot, while the upper ones will remain cold. On top of large stones lay out stones of medium size and then, with a top layer, small pebbles..

If the stones are improperly placed, the steam in the room will become wet and heavy, and the healing procedure of soaring will become ineffective.

As in the case of other types of furnaces, in the manufacture of a metal furnace the firebox can be designed as a single piece. This design is installed directly in the steam room. This option is the simplest. A large number of drawings and diagrams are available for those who wish. The option with a portable firebox is more laborious, but having an adequate supply of patience, it is quite possible to implement it.

The important point is the design of the chimney when installing a metal furnace. This compartment must be isolated. Optimally between the inner and outer casing of the pipe to lay the insulating sheet.

Metal furnaces have one interesting feature. The design of the furnace of most furnaces is such that it allows you to get the maximum heat in a minimum of time due to the rapid burning of firewood.

A situation arises when the wood has burned out and heated the furnace to high temperatures, which cannot be controlled. This happens because, as a standard, the furnace is equipped with a grate, which is designed to enhance combustion by supplying additional air, which means oxygen through its grates. With this device, the top of the furnace heats up very much, while the bottom and sides are very slightly. There are additional inconveniences in operation, because there is little pleasure - instead of bathing procedures, to regulate the flame.

The solution of the problem is simple, as all ingenious is to completely abandon the grate. If the firebox door is maximally sealed with an asbestos cord, the wood can be laid directly on the bottom of the stove. A small hole with a flap must be fitted on the door in order to be able to control the access of air to the fire.

After such actions, the wood in the stove will quietly burn for an hour or more, and the stove itself will warm up evenly. So simple, but effective adjustment of the design will make the metal furnace as convenient as possible.

The most common model of the metal sauna stove is the “stove”. Such a furnace is mobile, the easiest to manufacture and operate, and is familiar even to those who are far from the furnace works.

This design contains all the key elements:

- foundation;

- firebox and blew;

- grate;

- internal heater;

- chimney;

- water tank.

Near the stove it is possible to equip a place for storing firewood.

To install the simplest version of this furnace, you will need a welding machine, a section of a pipe with thick walls or a barrel like the furnace body itself and containers under water, a chimney pipe, a grate or rods for its manufacture, an insulating material.

First, prepare the base. To do this, free up a section of the floor and dig a pit with a depth of about 50 cm. Its size should be the size of a furnace with an additional 30 cm around the perimeter.A layer of rubble or crushed brick is lined at the bottom, and then it is poured with a layer of concrete. The next layer is a ruberoid sheet. It will be useful to lay it in two layers, but only after the concrete is completely dry..

Two layers of refractory brick are placed on the ruberoid sheets. The first layer on the edge. Burnt brick will create a good protection of the foundation against moisture and the effects of exposure to high temperatures.

The next stage is the assembly of the fuel compartment. The pipe, which will be used under the firebox, is cut off from two sides, in order to finally get a cylinder. In this cylinder, you need to cut a hole in which the firebox and the ash tube will be installed. Inside the pipe you need to weld fixings for the grate. The lattice itself also needs to be welded from metal rods.

Next, you need to prepare two circles cut from sheets of metal, weld them to the top of the pipe one and below the other, after making a hole to install the future chimney. Doors are made of metal residues.

For correct operation of the chimney, it is necessary to observe the sequence of its installation. The inside must be welded to the stove and the water tank installed on top so that the chimney pipe passes through the tank. In one of the walls of the tank you need to insert a tap.The rest of the length of the pipe must be removed from the premises. It is also necessary to insert a valve into the chimney pipe that looks like a metal rod with a circle fixed on it. Turning the valve, you can control the incoming air.

Sometimes it is better to install a water tank near the stove.. In this case, the tank and the fuel compartment are connected by metal tubes for circulation. This design allows you to mount a box for stones above the firebox, that is, to build a complete heater.

Simple homemade options

In addition to the brick and main metal furnaces, there are also the most simplified devices for heating the bath. You can build them from improvised means, making minimal effort. Of course, you need to understand that such designs are unlikely to be of particular beauty or to ennoble the interior, but if the goal is only in heating the room, it is quite acceptable to use such options.

When planning to build such a furnace, it is advisable to prepare a drawing or scheme according to which it will be assembled.

An interesting variant of the furnace may come from unnecessary wheels.. Such a heating element is simple in design, takes up little space, heats up quickly and gives off heat well. In addition, such a furnace will be durable, durable and, if desired, it can be heated not only with wood, but also with coal.

The downsides are those that are inherent in all metal furnaces - rapid cooling and the likelihood of getting burned by accidental contact with the wall. Also it must be borne in mind that due to the small size, such a furnace can warm a small room, ideally no more than 14-15 square meters. m, for heating more space, this design is not suitable.

The case of the device requires 4 discs from the truck, which must be pre-prepared - cleaned of dirt, possibly using emery cloth. Two discs need to remove the middle, leaving only the rim. They will be used as a water bottle. To do this, they need to be welded to each other and to the top of the metal cover to fill the water, and at the bottom of the structure to attach a metal sheet, which should have an opening for the chimney pipe. The resulting container must be sealed.It is necessary to check and eliminate deficiencies in their presence.

The remaining two discs are made of the fuel compartment and the heater. In one disc you need to leave the central part, it will play the role of the grate grate. The second disc must be freed from the central segment, then when welding two parts, the second will serve as a container for stones.

All parts of the furnace are assembled according to the scheme, after which the furnace is installed on a previously prepared foundation.

A stove made of an unusable iron barrel can also be a good option for small steam rooms.. To install such a furnace in the first place you need to lay the foundation. It should be a concrete or brick base, which has a high fire resistance.

Barrel need to trim the grinder to the required length. After that, the brick is laid out inside. The fuel compartment is allocated with metal profiles. Stones are piled on them. After that, a lid with a welded smoke pipe is installed on the barrel.

Such a furnace will heat up and give its heat to the stones, and the smoke will fall into the gaps between them and evaporate.

Useful recommendations

When planning the construction of a bath stove, it is important to properly assess your strengths and capabilities. Of course, a stove made with your own hands will heat not only the body, but also the soul. But in order for such a fascinating and fruitful exercise to bring pleasure, you need a serious approach.

Manufacturers of stoves for baths offer a wide range of ready-made devices that only require installation. If you still bother to build the furnace yourself, be sure to take into account all the tips and recommendations.

It is strictly impossible to neglect the requirements of fire safety. There must be insulation of the foundation. It must be remembered that for stoves operating on different types of fuel, safety criteria will vary. The most unreliable option is a unit that uses diesel, diesel fuel, liquid combustible mixtures as fuel.

It is necessary to foresee in advance how the issue of ventilation in the bath will be solved. Proper installation of the chimney will avoid the leakage of smoke and carbon monoxide poisoning.

Carefully study the needs of your family in relation to bath procedures.Based on this information, you can decide in favor of which furnace to make a choice. A metal oven will quickly heat the steam room and if in your case the duration of the bath procedures is a couple of hours, then it makes sense to install a metal structure.

For lovers of the steam brick oven would be a more suitable option.as long it keeps heat and generates soft comfortable steam.

The metal walls of the furnace can be lined with brickwork, you get some kind of medium version, which has advantages and brick and metal furnace

An excellent bath solution will be to purchase a cast-iron finished furnace. with the subsequent facing of its walls with bricks. The steam from such a furnace will be pleasant and dense, and the furnace itself will last a long time. Another advantage of this option is fast heating. But we must remember that Such a furnace is not installed directly in the steam room. Her chelie must be in the waiting room.

It is good when the stove is designed in such a way that both types of stoves are present - closed and open. So more opportunities to bring the steam room to the desired temperature. Kamenka can be arranged in the form of a grid filled with stones. Less metal - less hot heat.

Stones can be laid in a certain way in the form of a well, so that you can pour water directly into the designed recess. This will give a large amount of good quality steam.

In addition to a good stove, it is important to properly make the thermal insulation of the steam room, the drain for water and the entire internal structure of the sauna, including the wall covering. You may have to think about how to organize additional heating to accommodate the wishes of all family members.

The best fuel for the bath will be birch firewood. They burn evenly, leaving little waste. Coniferous trees during combustion very clog up the chimney. It is better not to use them.

The volume of the water tank, as a rule, is calculated from the amount of 10 liters for washing one person.

Clay for mortar used for laying bricks, you can fully use the natural, collected on the banks of reservoirs. It should be soaked for several days to clear from possible impurities.

Drawing attention to all the subtleties and nuances of the furnace business, you can build a device that will bring joy and health.

See the next video for a master class in making the stove.